Method for preparing synthetic terephthalic acid-1,3-trimethylene glycol ester

A technology of polyterephthalic acid and dimethyl phthalate, applied in the field of synthesizing polyterephthalic acid 1, to overcome the effects of long synthesis time, shortened reaction time, and poor light stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

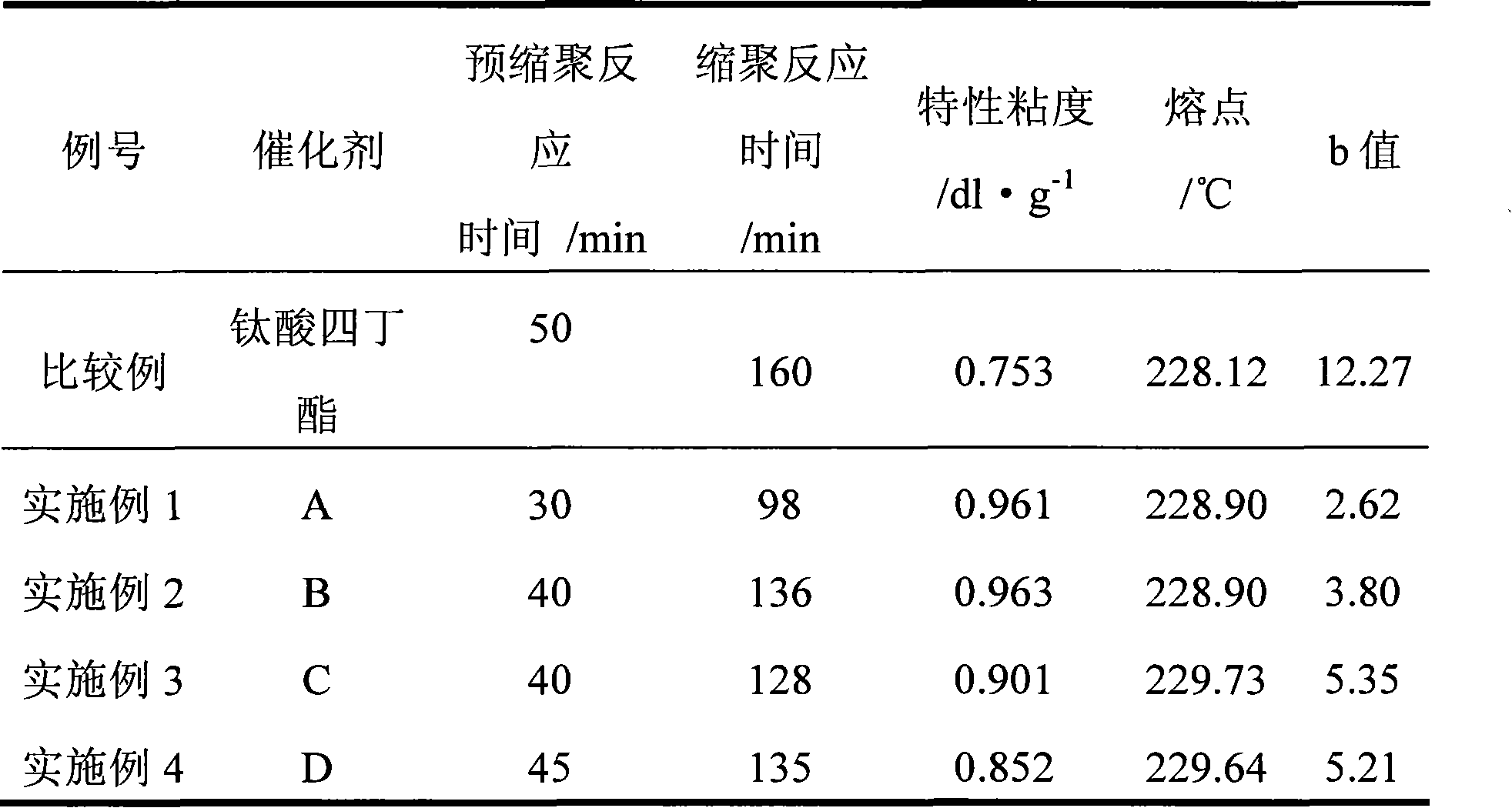

Examples

Embodiment 1

[0021] Preparation of Catalyst A

[0022] In a reactor equipped with a stirrer and a thermometer, add 100g of 1,3-propanediol, add 1.5g of germanium oxide, add 3.0g of cobalt acetate tetrahydrate, slowly add n-tetrabutyl titanate into the reactor while stirring 3.75 g of ester was stirred for 30 min to obtain a mixed solution. Called Catalyst A.

[0023] 1000 grams of purified terephthalic acid (PTA), 650 grams of 1,3-propylene glycol (1,3-PDO) and an appropriate amount of catalyst A are mixed into a slurry and added to the polymerization kettle (wherein the content of the catalyst in the PTA weight is : Tetrabutyl titanate is 375ppm, cobalt acetate tetrahydrate is 300ppm, germanium oxide is 150ppm), carry out esterification reaction, the pressure is 0.2MPa, the esterification temperature is 230-250 ℃, the by-product is distilled out in the reaction kettle When the amount of product water reaches the theoretical water output, the pressure in the kettle returns to normal pres...

Embodiment 2

[0025] Preparation of Catalyst B

[0026] In a beaker, add 100g of 1,3-propanediol, add 2.5g of germanium oxide, add 1.5g of cobalt phosphate, add 2.0g of tetraisopropyl titanate, place in an ultrasonic system for mixing for 15min, and heat to 70°C at the same time to obtain Homogenous mixture. Call it Catalyst B.

[0027] Preparation of polyester

[0028] Polyester was prepared by the same method as in Example 1, using catalyst B as the reaction catalyst, wherein the content of the catalyst in the mass of PTA was: 200ppm tetraisopropyl titanate, 150ppm cobalt phosphate, and 250ppm germanium oxide.

Embodiment 3

[0030] Preparation of Catalyst C

[0031] Catalyst D was prepared by the preparation method of catalyst A, adding 100g of 1,3-propanediol, adding 1.0g of germanium oxide, adding 1.0g of cobalt nitrate, adding 3.0g of tetrapropyl titanate, heating to 80°C at the same time, and stirring for 60min to obtain a uniform Mixture. Called Catalyst C.

[0032] Preparation of polyester

[0033] Polyester was prepared by the same method as in Example 1, using catalyst C as the reaction catalyst, wherein the content of the catalyst in the mass of PTA was: 300ppm tetrapropyl titanate, 100ppm cobalt nitrate, and 100ppm germanium oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com