Process for synthesizing polycrystal lattice laminal compound

A technology of layered compounds and synthesis methods, applied in chemical instruments and methods, polycrystalline material growth, single crystal growth, etc., to achieve the effect of design synthesis and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: the synthesis of polylattice nickel niobium oxide hydroxide

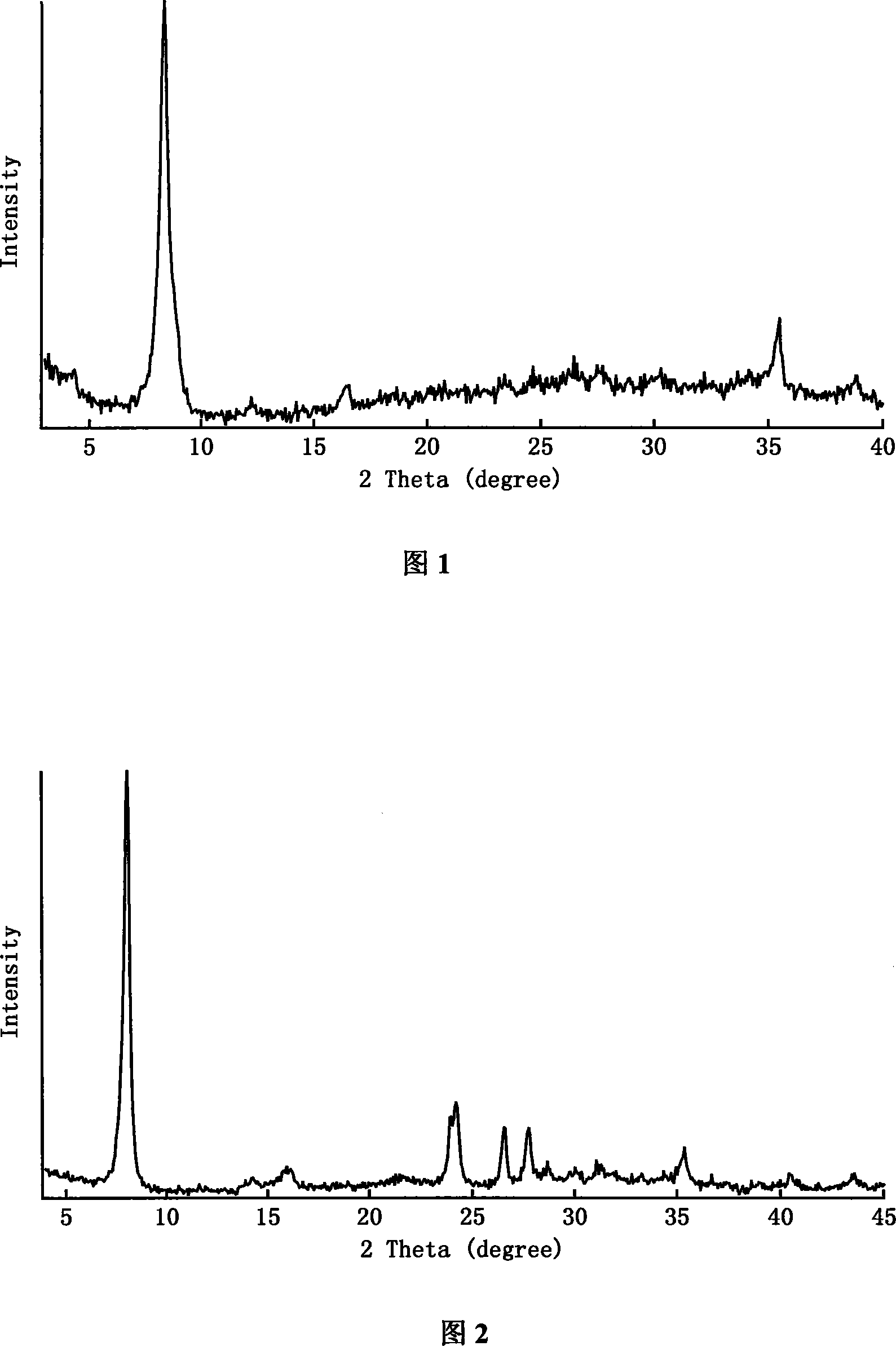

[0024] Take 1mmol of K 4 Nb 6 o 17 Perform proton exchange in 40ml of 1M HCl, add the exchanged product to 30ml of water containing 5mmol of n-propylamine, and after hydrothermal treatment in an oven at 120°C for 1 day, add 4mmol of NiCl 2 Wash the resulting precipitate with deionized water to PH=6-10, put it into a reaction kettle, use water as the reaction medium, and put it in an oven at 160°C for 3 days. The solid powder X-ray diffraction spectrum is shown in the figure 1.

Embodiment 2

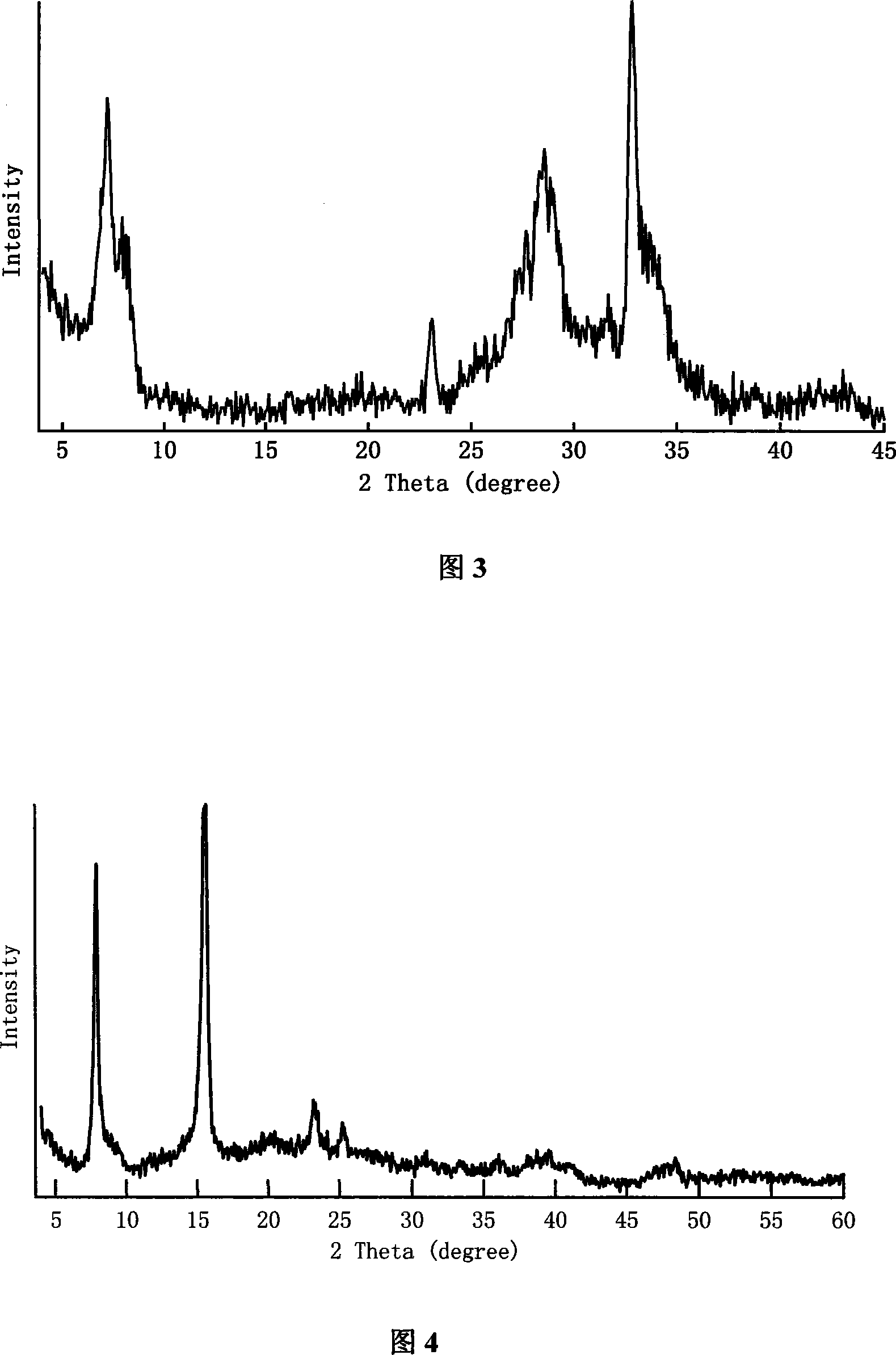

[0025] Example 2: Synthesis of polylattice nickel titanium niobium oxide hydroxide

[0026] 1mmol of KTiNbO 5 Perform proton exchange in 10ml of 1M HCl, add the exchanged product to 30ml of water containing 1.5mmol of n-propylamine, put it in a 100°C oven for hydrothermal treatment for 1 day, and then add 1mmol of NiCl 2 , wash the generated precipitate with deionized water to PH=6-10, put it into a reaction kettle, use water as the reaction medium, and put it in an oven at 260 ° C for 1 day. The solid powder X-ray diffraction spectrum is shown in Figure 2 Show.

[0027]Use tetramethylamine hydroxide, tetraethylamine hydroxide, tetrabutylamine hydroxide, tri-n-propylamine, n-butylamine, ethylamine, methylamine, n-pentylamine, n-hexylamine, cyclohexylamine and other organic amines instead of n-propylamine , the same product can also be obtained.

Embodiment 3

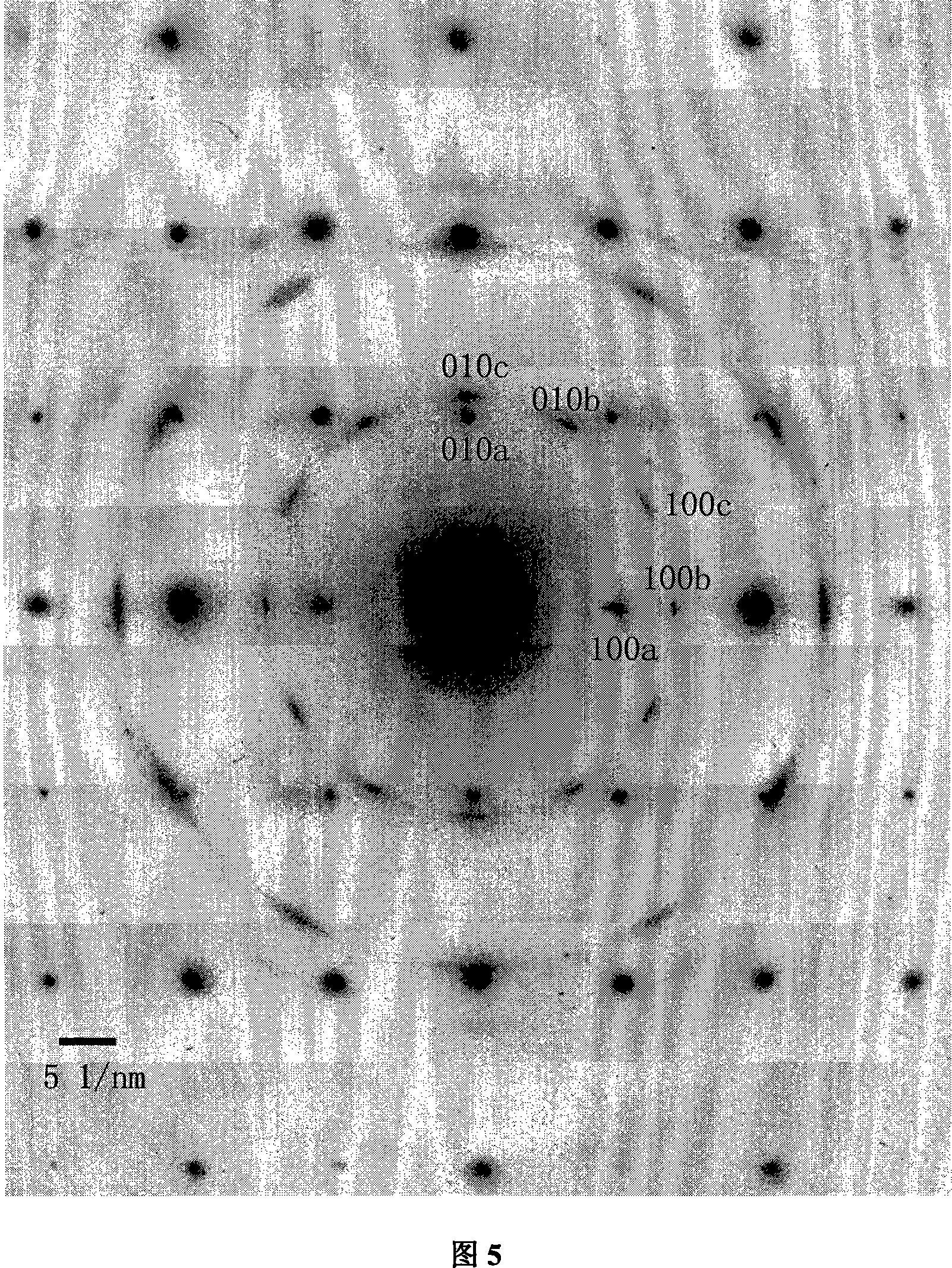

[0028] Embodiment 3: Synthesis of polylattice nickel zirconium lanthanum niobium oxide hydroxide

[0029] 1mmol of KLaNb 2 o 7 Perform proton exchange in 10ml of 0.5M HCl, add the exchanged product to 30ml of water containing 1mmol n-butylamine, put it in a 120°C oven for hydrothermal treatment for 12 hours, then add 0.5mmol of NiCl 2 and 0.5 mmol of ZrOCl 2 , wash the generated precipitate with deionized water to PH=6-10, put it into a reaction kettle, use water as the reaction medium, and put it in an oven at 160°C for 3 days. The solid powder X-ray diffraction spectrum is shown in Figure 3 Show.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com