Encapsulation structure and high heat conducting reflexion cap of diode point matrix / nixie tube

A reflective cover, high thermal conductivity technology, applied in the direction of identification devices, instruments, etc., can solve the problems of printed circuit wiring difficulties, increase energy consumption, large printed circuit board space, etc., to reduce the pixel pitch of the display, prolong the service life, The effect of smooth cooling channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

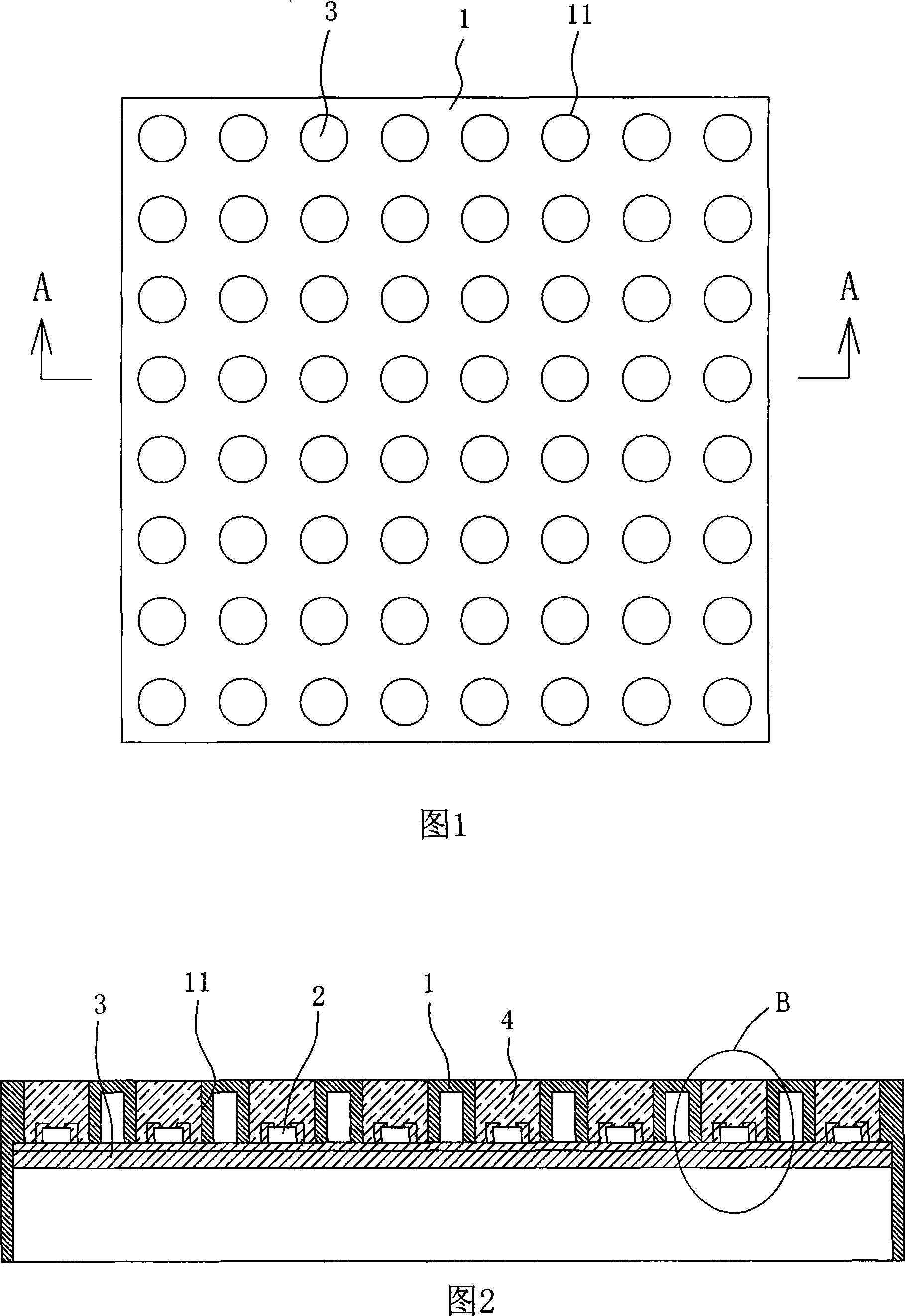

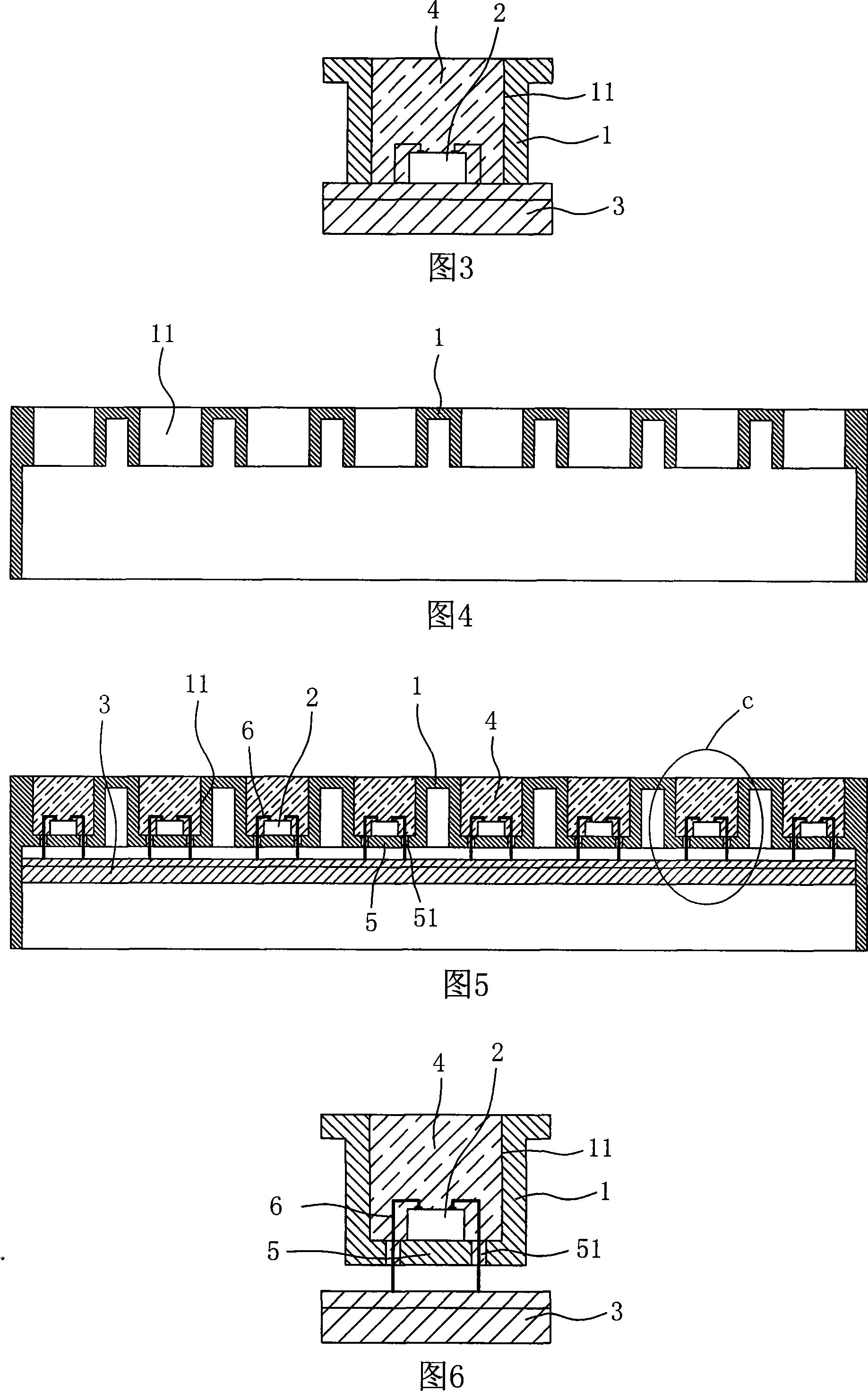

[0023] Embodiment 1: Refer to Fig. 5 to Fig. 7 . The packaging structure of the light-emitting diode dot matrix / digital tube mainly includes a reflective cover 1, an LED chip 2, a printed circuit board 3, and a transparent package for packaging the LED chip.

[0024] Refer to Figures 5 to 7. The reflective cover is made of high thermal conductivity materials such as aluminum, copper, aluminum-copper alloy or high thermal conductive ceramics; the reflective cover 1 is provided with pixel holes 11 arranged in a dot matrix in multiple rows. The bottom of each pixel hole 11 of the reflective cover 1 is provided with a bridging bottom 5 integrally formed with the reflective cover for fixing and installing the LED chip 2; the bridging bottom 5 is a circular plate matching the bottom surface of the pixel hole, and the circular plate Line passing holes 51 are correspondingly provided on both sides of the middle part. The circuit board 3 is fixedly embedded in the inner cavity of the...

Embodiment 2

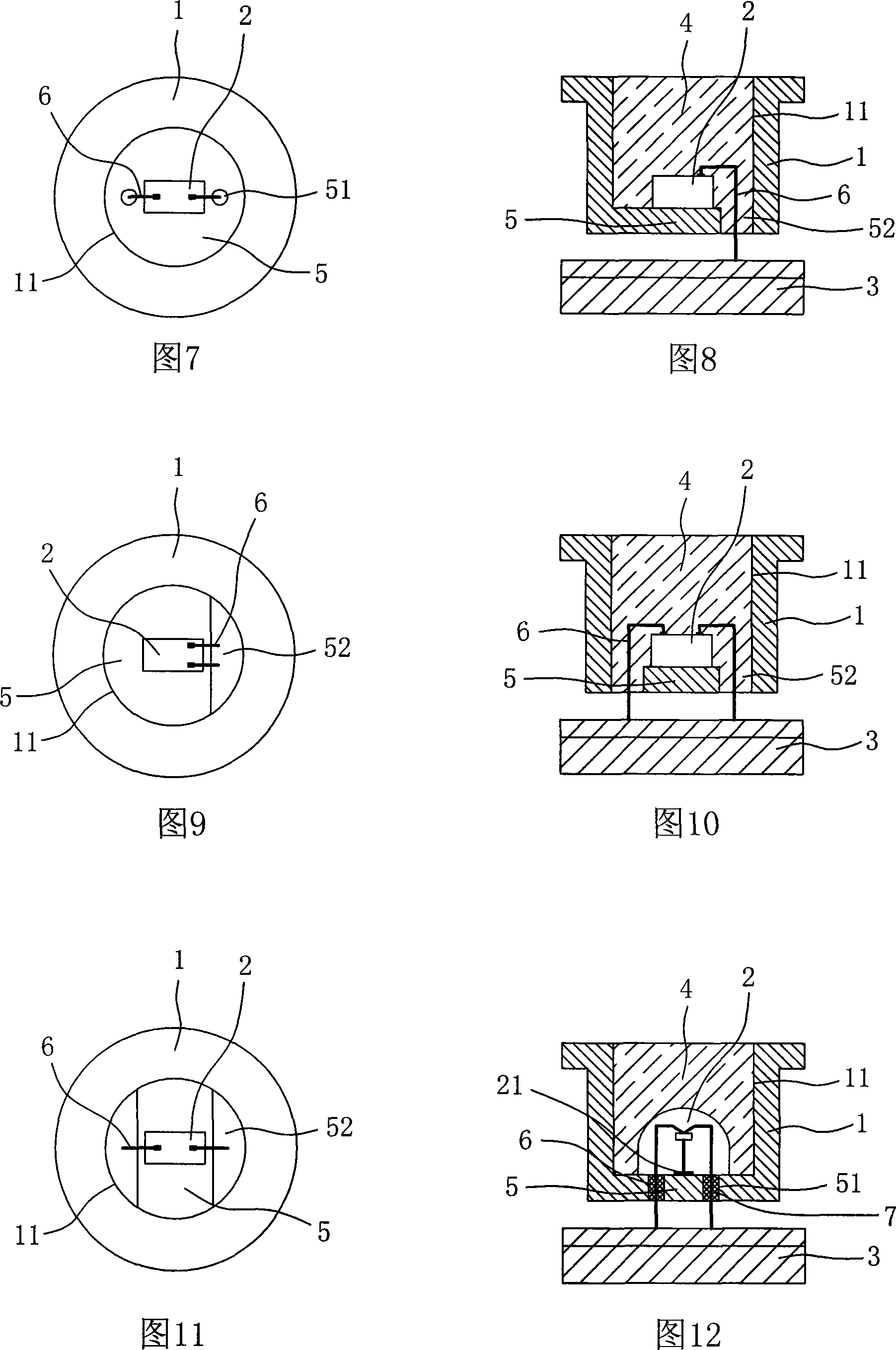

[0026] Embodiment 2: Refer to Fig. 8 and Fig. 9 . The difference between this embodiment and embodiment 1 is:

[0027] The bridging bottom 5 at the bottom of each pixel hole 11 of the reflective cover 1 is a D-shaped plate matching the bottom surface of the pixel hole. There is a gap 52 between one side of the D-shaped plate and the inner wall of the pixel hole 11, and the gap 52 forms a line. space. The LED chip 2 is inverted and fixed on the top surface of the bridging bottom 5 by gluing or eutectic welding. The two terminals on the front of the LED chip 2 are connected to the circuit board 3 through the gold wire 6 respectively. One end is electrically connected to the corresponding terminal on the front of the LED chip 2 , and the other end is electrically connected to the corresponding electrode of the circuit board 3 through the gap 52 . The rest of the structure is the same as that of Embodiment 1, and will not be repeated here.

Embodiment 3

[0028] Embodiment 3: Refer to Fig. 10 and Fig. 11 . The difference between this embodiment and embodiment 1 is:

[0029] The bridging bottom 5 at the bottom of each pixel hole 11 of the reflector cover 1 is an inline strip that is bridged between the middle parts of both sides of the inner peripheral wall of the pixel hole, and there is a gap 52 between the two sides and the inner wall of the pixel hole. The void 52 forms the wire passing space. The LED chip 2 is fixed upside down on the top surface of the bridging bottom 5 by gluing or eutectic welding. The two terminals on the front of the LED chip 2 are connected to the circuit board 3 through the gold wire 6 respectively. One end is electrically connected to the corresponding terminal on the front of the LED chip 2 , and the other end is electrically connected to the corresponding electrode of the circuit board 3 through the gap 52 . The rest of the structure is the same as that of Embodiment 1, and will not be repeated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com