Vehicle bridge shell semi-housing mold method and special forming mold

A technology for forming molds and half shells, applied in the directions of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of reducing the bearing capacity and service life of automobile axle housings, increasing labor and mold investment, and increasing parts production costs, etc. Achieve the effect of improving the use strength and bearing capacity, shortening the manufacturing cycle and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

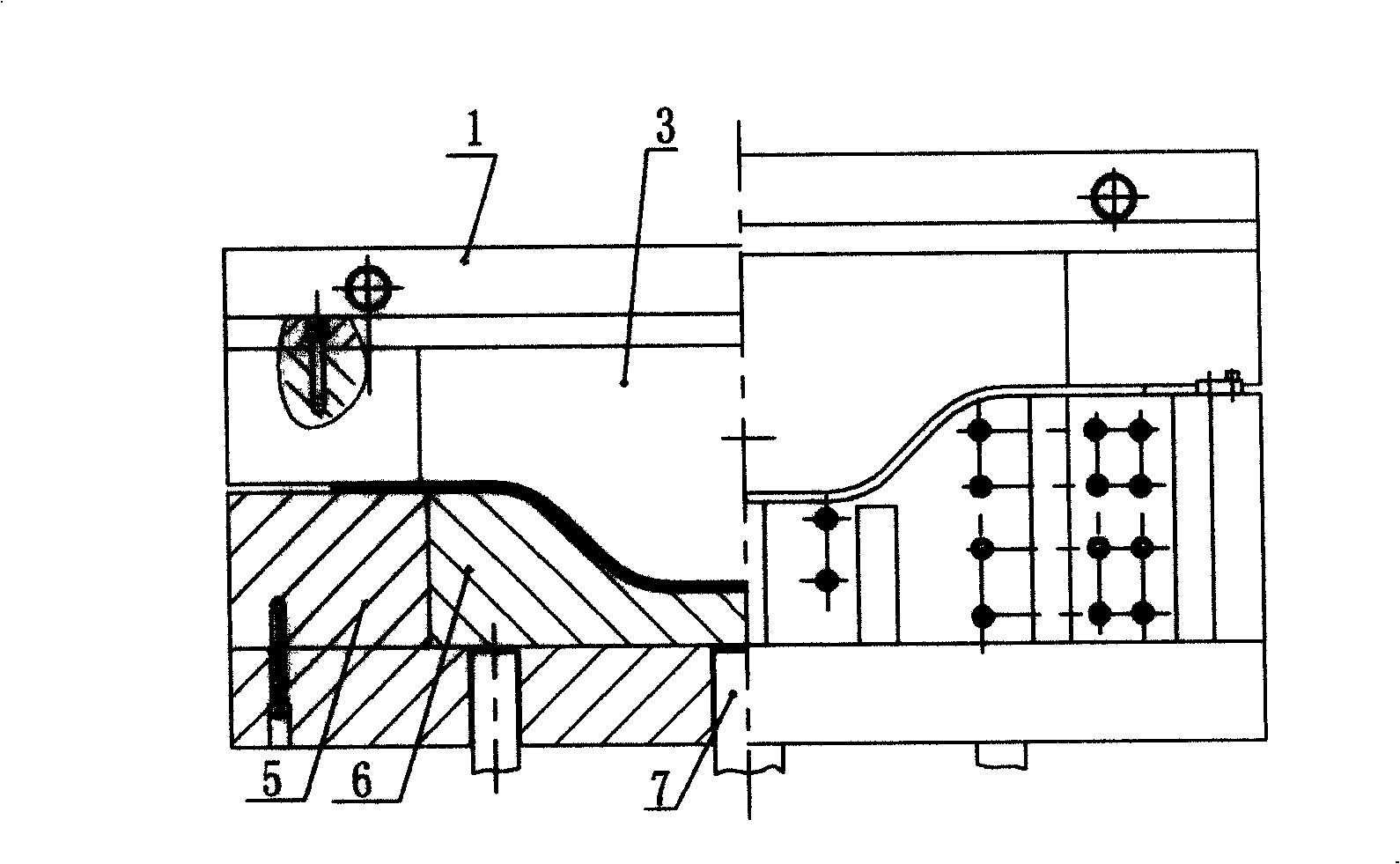

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

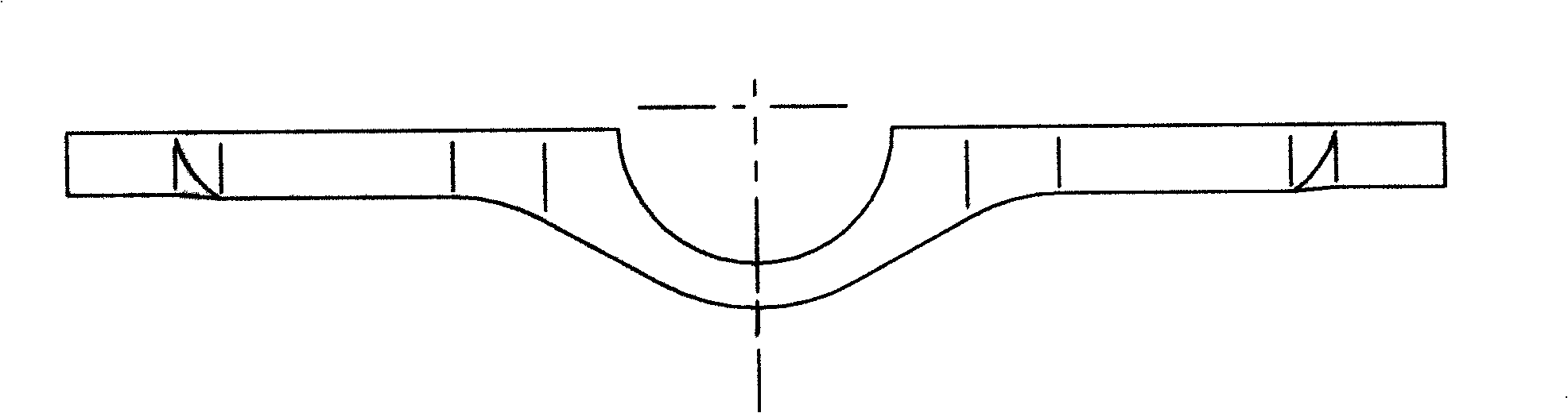

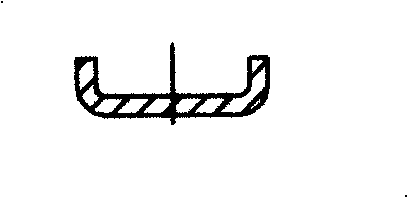

[0022] The car shell half-shell cold-bending forming method of the present invention is illustrated by taking 13 tons of middle and rear axle half-shells as an example. The axle shell half-shell forming method is to adopt steel plate direct cold-bending forming, and the specific steps are:

[0023] Select a hot-rolled steel plate with a grade of 16MnL and a thickness of 20mm. According to the shape of the half-shell, use a CNC cutting machine to cut the material. Install the forming die on a 25000-30000KN hydraulic press and debug it. The blank is put into the installed and debugged On the forming die, start the hydraulic press to make it go down to punch the wool into shape, and after keeping it in the forming die for 20 seconds, start the hydraulic press to go up and push out the half-shell formed part by the ejector rod.

[0024] When selec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com