Method for preparing high-pure molybdenum oxide by vacuum decomposition of molybdenite

A technology of molybdenum oxide and molybdenite, applied in the direction of molybdenum oxide/molybdenum hydroxide, etc., can solve the problems of complex preparation process, high processing cost, and threat to the ecological environment, so as to improve the comprehensive efficiency of resources and avoid the comprehensive treatment of SO2 Burden and related emissions, effects of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

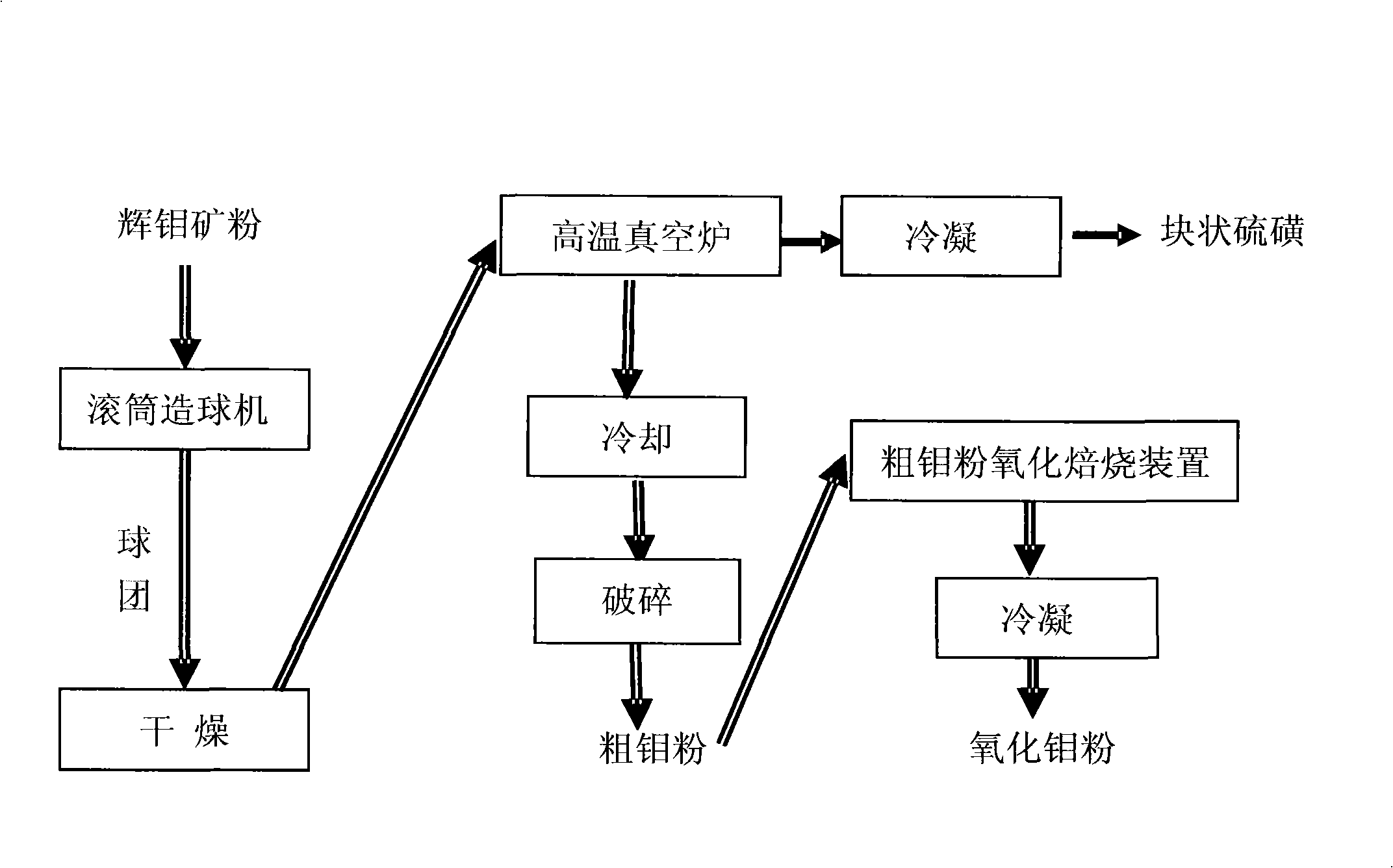

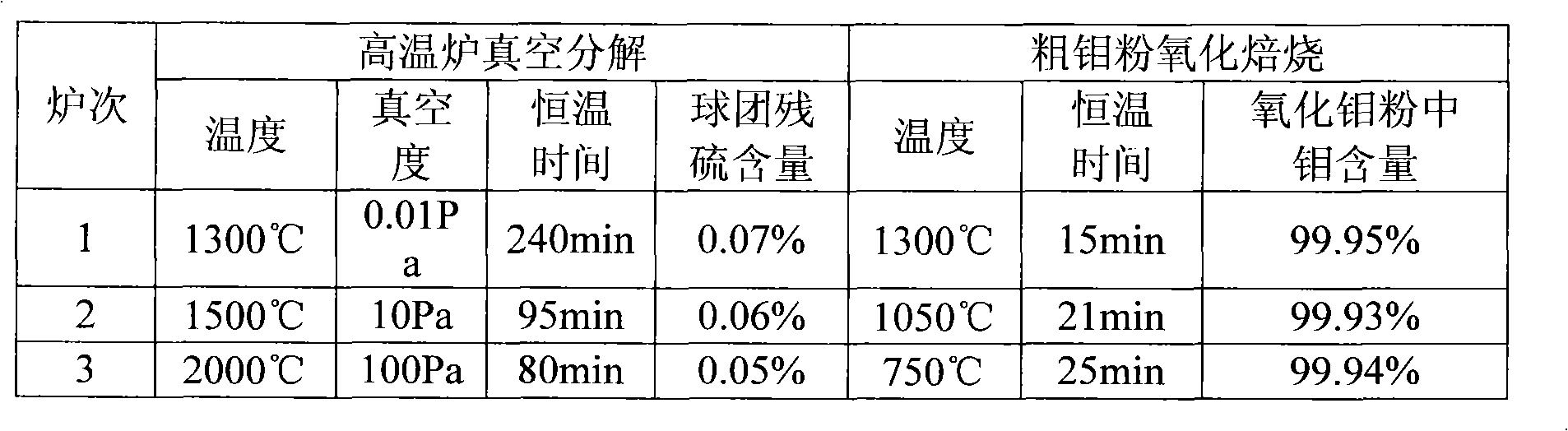

[0025] Such as figure 1 Shown: The method for preparing high-purity molybdenum oxide by vacuum decomposition of molybdenite, high-purity molybdenum oxide MoO is prepared by two-step method 3 , the first step is to prepare molybdenum powder with extremely low content of non-ferrous metal impurities and sulfur S, and the second step is to oxidize the molybdenum powder into high-purity molybdenum oxide by oxidation; in order to prepare high-purity MoO 3 , the grade of molybdenite must be improved, and the content of non-ferrous metal elements in it must be reduced as much as possible. The volatile non-ferrous metal elements, such as Pb, Zn, As, Sb, etc., are removed through a high-temperature vacuum furnace, and the sulfur content is also removed, but the graphite, Cu, Fe, SiO in the ore powder 2 , CaO, etc. cannot be removed by vacuum method. Therefore, the second step of the present invention is to oxidize the coarse molybdenum powder, because MoO 3 Very easy to gasify, by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com