System for acquisition and processing of x-ray diffraction data

A data acquisition and processing system technology, applied in the direction of material analysis using radiation diffraction, optical radiation measurement, radiation pyrometry, etc., can solve the problems that cannot meet the requirements of engineering microcomputerized automatic control, cannot carry out on-line automatic testing, and cannot adapt , to achieve the effect of improving work efficiency and quality, high positioning accuracy, and high analysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

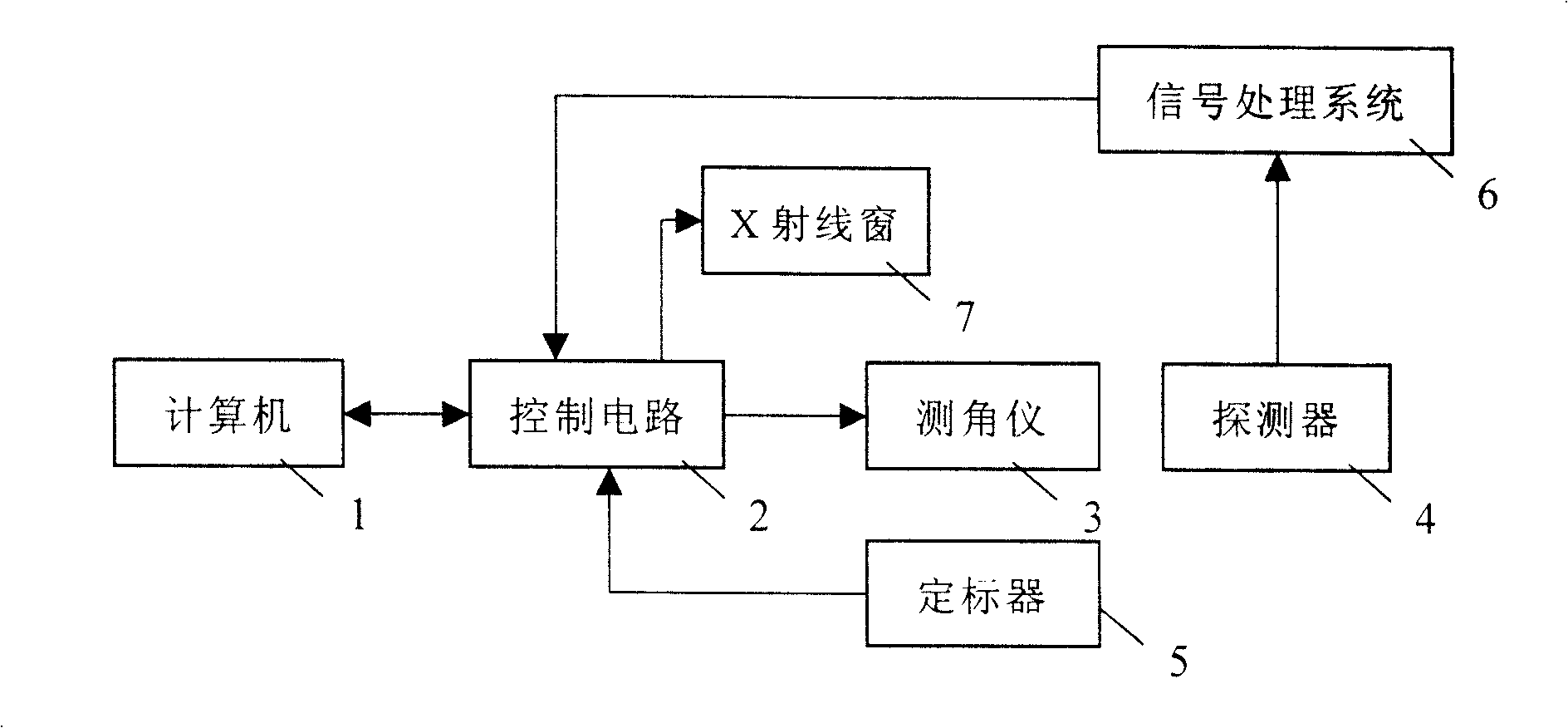

[0019] Such as figure 1 As shown, the X-ray diffraction data acquisition and processing system of the present invention includes a computer 1 , a control circuit 2 , a goniometer 3 , a detector 4 , a scaler 5 , a signal processing system 6 and an X-ray window 7 . The detector 4 and the scaler 5 are placed on the goniometer 3, the computer 1, the goniometer 3, the scaler 5, the signal processing system 6, and the X-ray window 7 are connected to the control circuit 2, and the detector 4 is connected to the signal processing System 6 is connected.

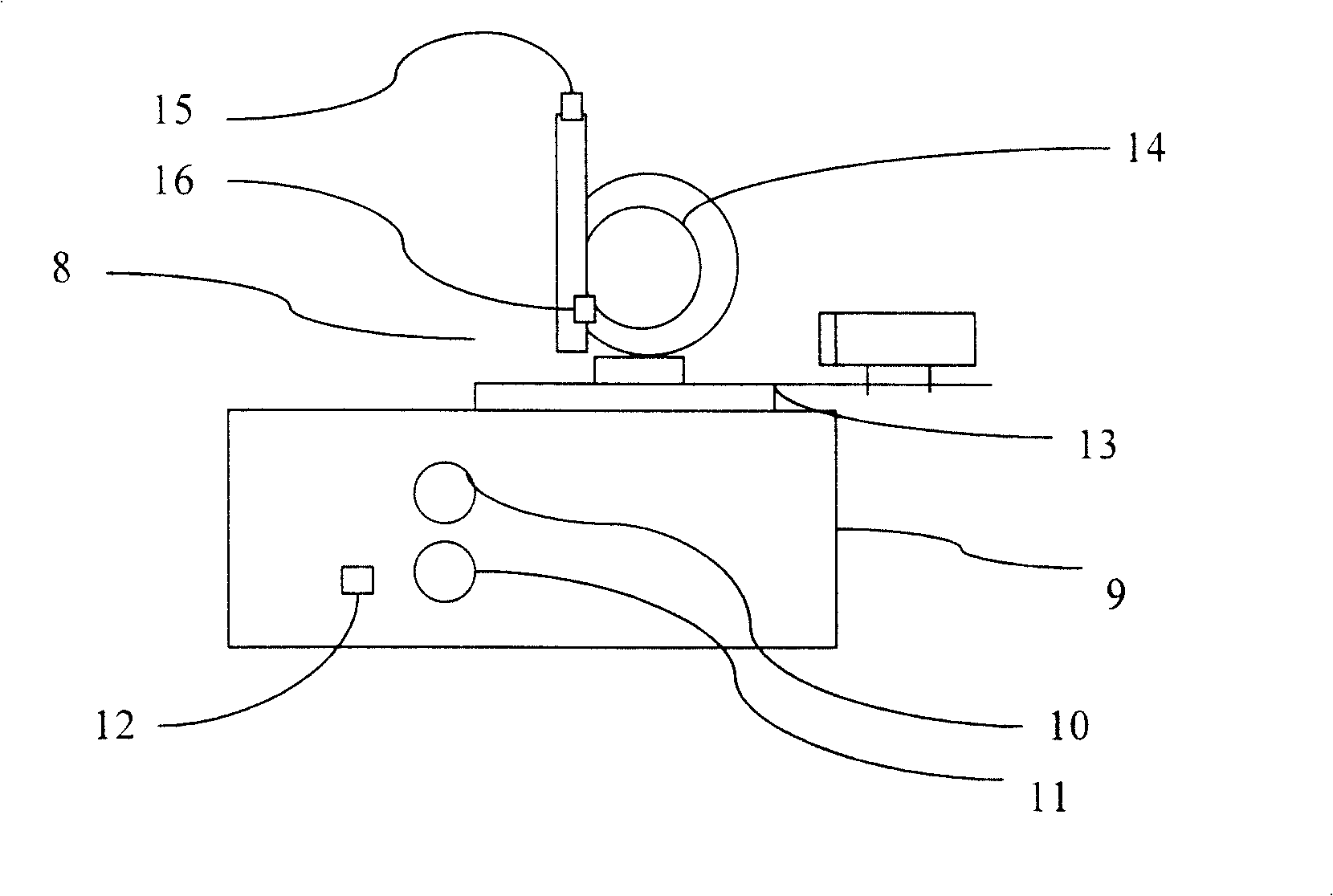

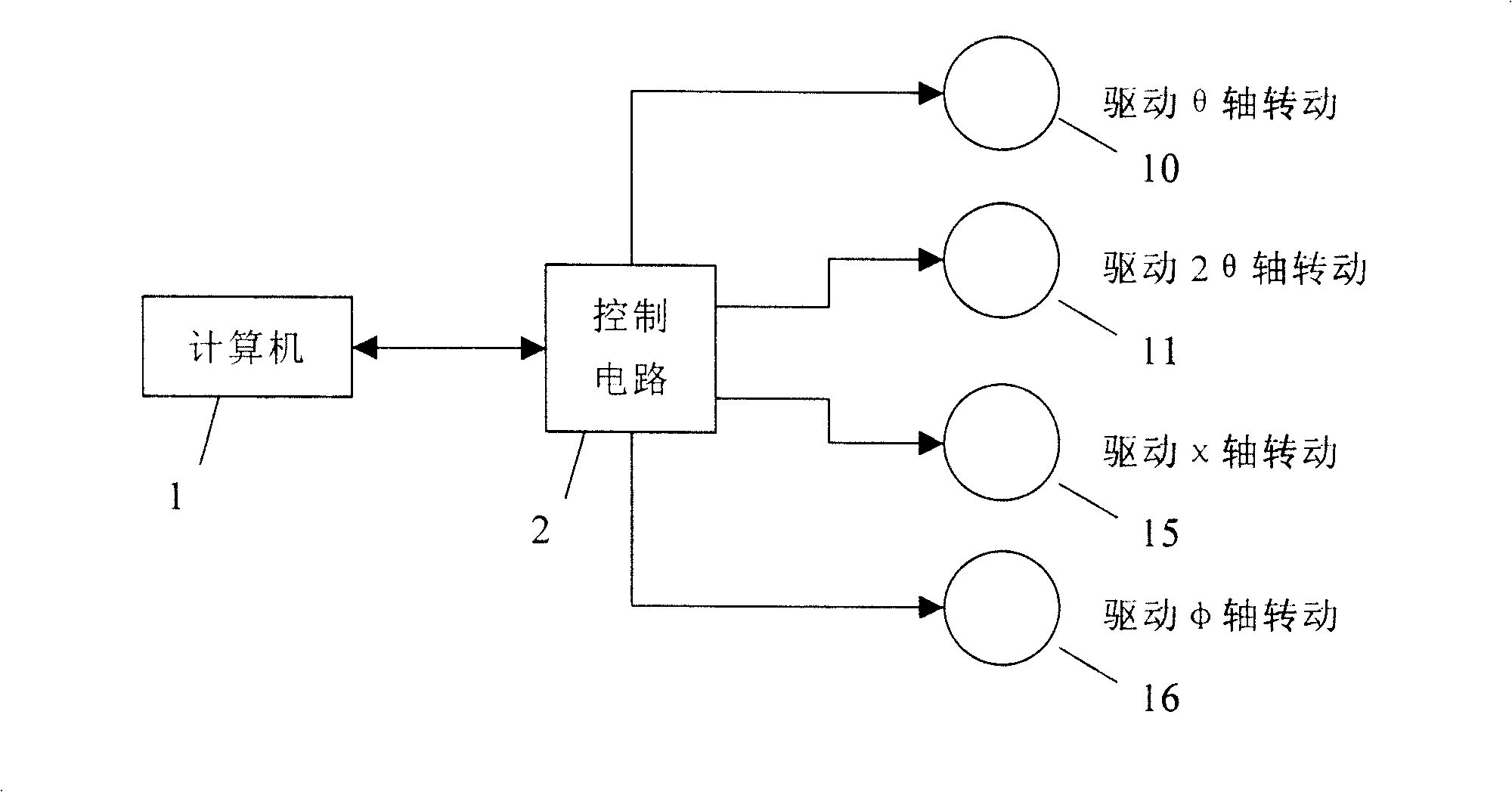

[0020] Such as figure 2 with image 3 As shown, the goniometer 3 includes a goniometer 8, a drive box 9, stepping motors 10, 11 and a clutch 12 that respectively drive the θ axis and the 2θ axis to rotate, the goniometer 8 includes a turntable 13, and the turntable 13 is installed in the drive box 9, two stepping motors 10, 11 and a clutch 12 respectively driving the θ axis and the 2θ axis to rotate are installed in the drive box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com