Deep impurity-removing method for crude tellurium powder

A technology of deep impurity removal and tellurium powder, applied in the direction of element selenium/tellurium, etc., can solve the problems of lengthy process, instability, and great impact on product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

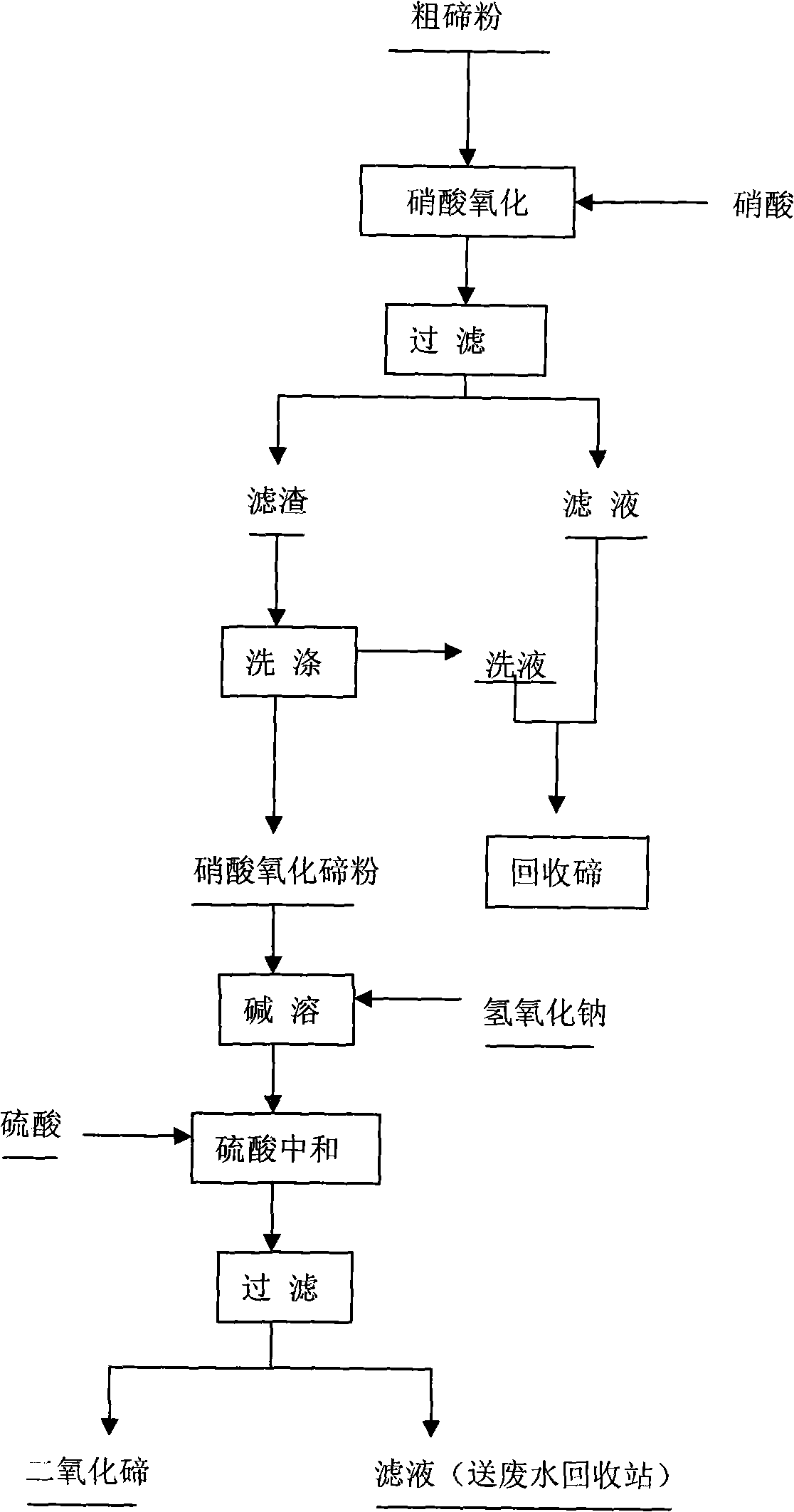

Method used

Image

Examples

Embodiment 1

[0017] Add the dried tellurium powder into the container, oxidize it with 1.2 times the theoretical amount of nitric acid to obtain tellurium oxynitrate powder, filter the filter residue and wash it with pure water until the pH value is 3; add 80g / l sodium hydroxide solution in the container, When the temperature rises to 30°C, add tellurium oxide nitrate powder until the tellurium oxide nitrate powder is completely dissolved, filter the solution, return the filtered solution to the container, slowly add sulfuric acid to neutralize while stirring, adjust the pH value to 4.0, filter Washing to obtain tellurium dioxide powder with a purity of 99.95.

Embodiment 2

[0019] Add the dried tellurium powder into the container, oxidize it with 2.5 times the theoretical amount of nitric acid to obtain tellurium oxynitride powder, filter the filter residue and wash it with pure water until the pH value is 4; add 80g / l sodium hydroxide solution in the container, When the temperature rises to 40°C, add tellurium oxide nitrate powder until the tellurium oxide nitrate powder is completely dissolved, filter the solution, return the filtered solution to the container, slowly add sulfuric acid to neutralize while stirring, adjust the pH value to 5.5, filter Wash to obtain tellurium dioxide powder with a purity of 99.98.

Embodiment 3

[0021] Add the dried tellurium powder into the container, oxidize it with nitric acid 1 times the theoretical amount to obtain tellurium oxynitrate powder, filter the filter residue and wash it with pure water until the pH value is 3; add 80g / l sodium hydroxide solution in the container, When the temperature rises to 50°C, add tellurium oxide nitrate powder until the tellurium oxide nitrate powder is completely dissolved, filter the solution, return the filtered solution to the container, slowly add sulfuric acid to neutralize while stirring, adjust the pH value to 7.0, filter Washing to obtain tellurium dioxide powder with a purity of 99.95.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com