Automatic snow-removing method

An automatic and geothermal technology, applied in the field of snow removal, can solve the problems of high remote operation cost, low work efficiency, and failure to promote, and achieve the effect of solving thoroughness and timeliness problems, simple and convenient operation, safe and reliable implementation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

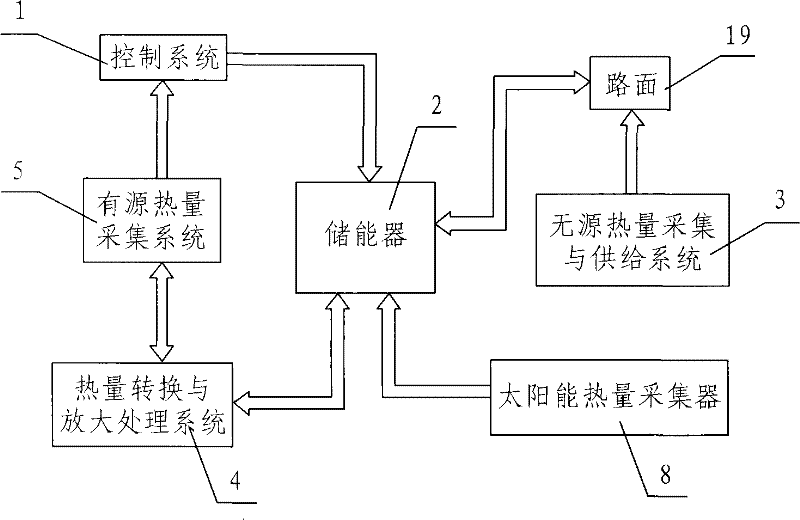

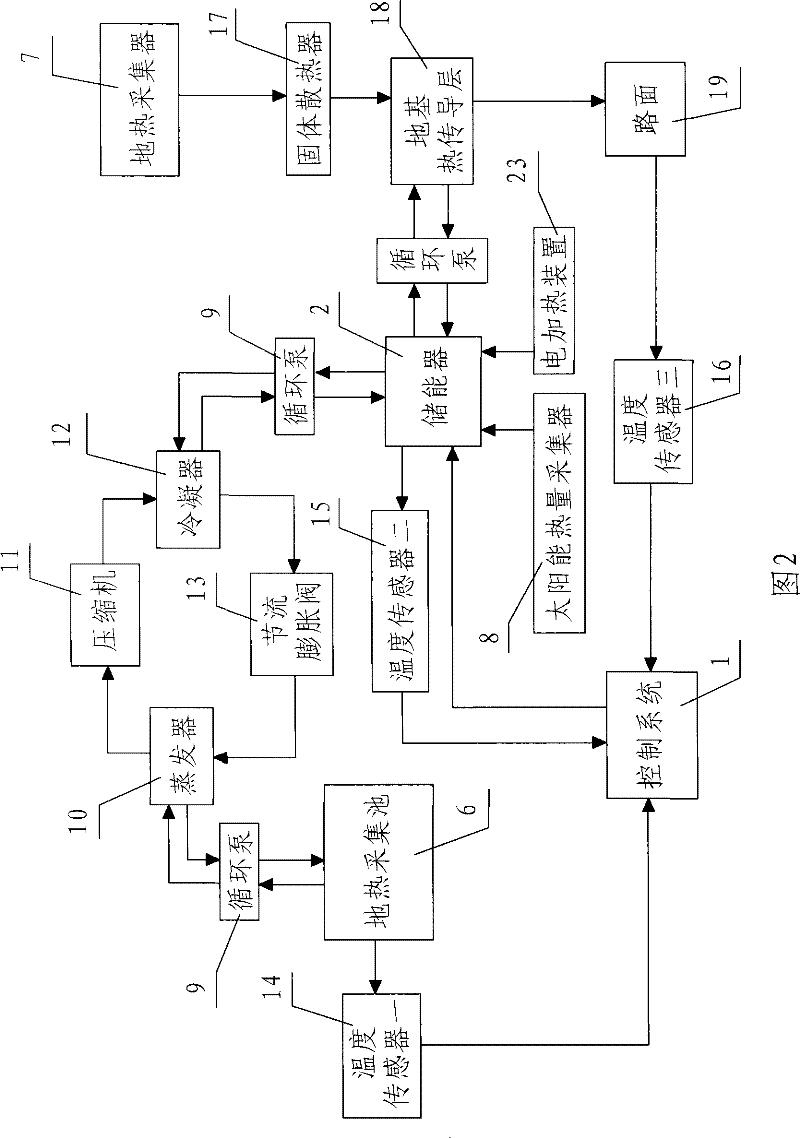

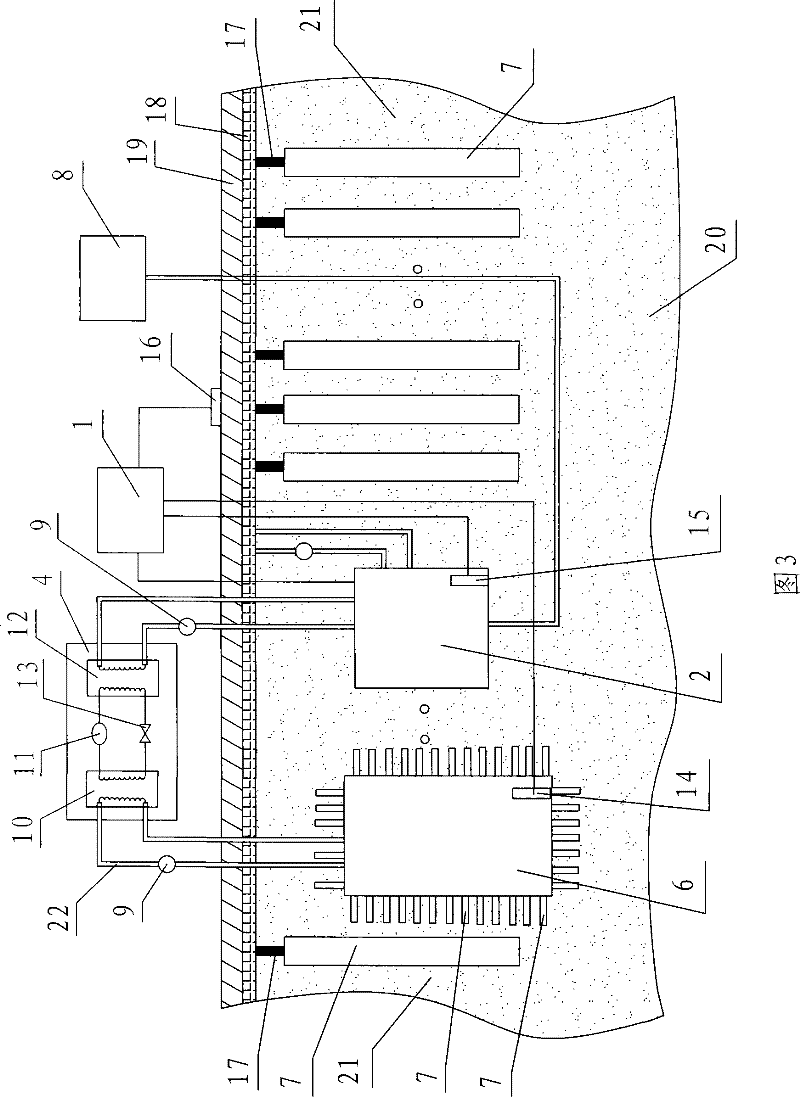

[0038] Combine figure 1 , figure 2 and image 3 , An automatic snow removal method of the present invention includes the following steps:

[0039] The first step, heat collection and real-time supply of part of the heat: The geothermal collection pool 6 buried in the underground soil 21 is used to collect and condense the heat in the soil in real time, and the surrounding walls of the geothermal collection pool 6 are evenly distributed with multiple geothermal Collector 7; At the same time, multiple geothermal collectors 7 buried in the underground soil 21 are used to collect the heat in the soil in real time, and the solid radiator 17 provides a real-time heat source for the foundation heat conduction layer 18 laid under the road 19; In addition, the solar heat collector 8 connected to the energy storage 2 also collects solar energy in real time.

[0040] Among them, the geothermal collection pool 6 is figure 1 In the active heat collection system 5 described in the above, a plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com