Visible light response method for preparing Bi2WO6 photocatalyst fused salt

A photocatalyst and visible light technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. Energy and equipment requirements are high, and the effect of low cost, low energy consumption and simple process is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1) take by weighing 40.2g lithium nitrate and the sodium nitrate of 34.24g, mix as reaction medium after;

[0018] 2) According to the weight ratio of reaction medium and oxide raw material 20:1, weigh 2.56g of bismuth oxide and 1.16g of tungsten oxide;

[0019] 3) The reaction medium and the oxide raw material with a weight ratio of 20:1 are added with absolute ethanol, mixed evenly, put into an oven, and dried at 80°C;

[0020] 3) Put the obtained mixture of the reaction medium and the oxide raw material into an alumina crucible, put it into a resistance furnace, raise the temperature to 350° C. at a rate of 3° C. / min, and keep it warm for 8 hours to obtain a solid reaction product;

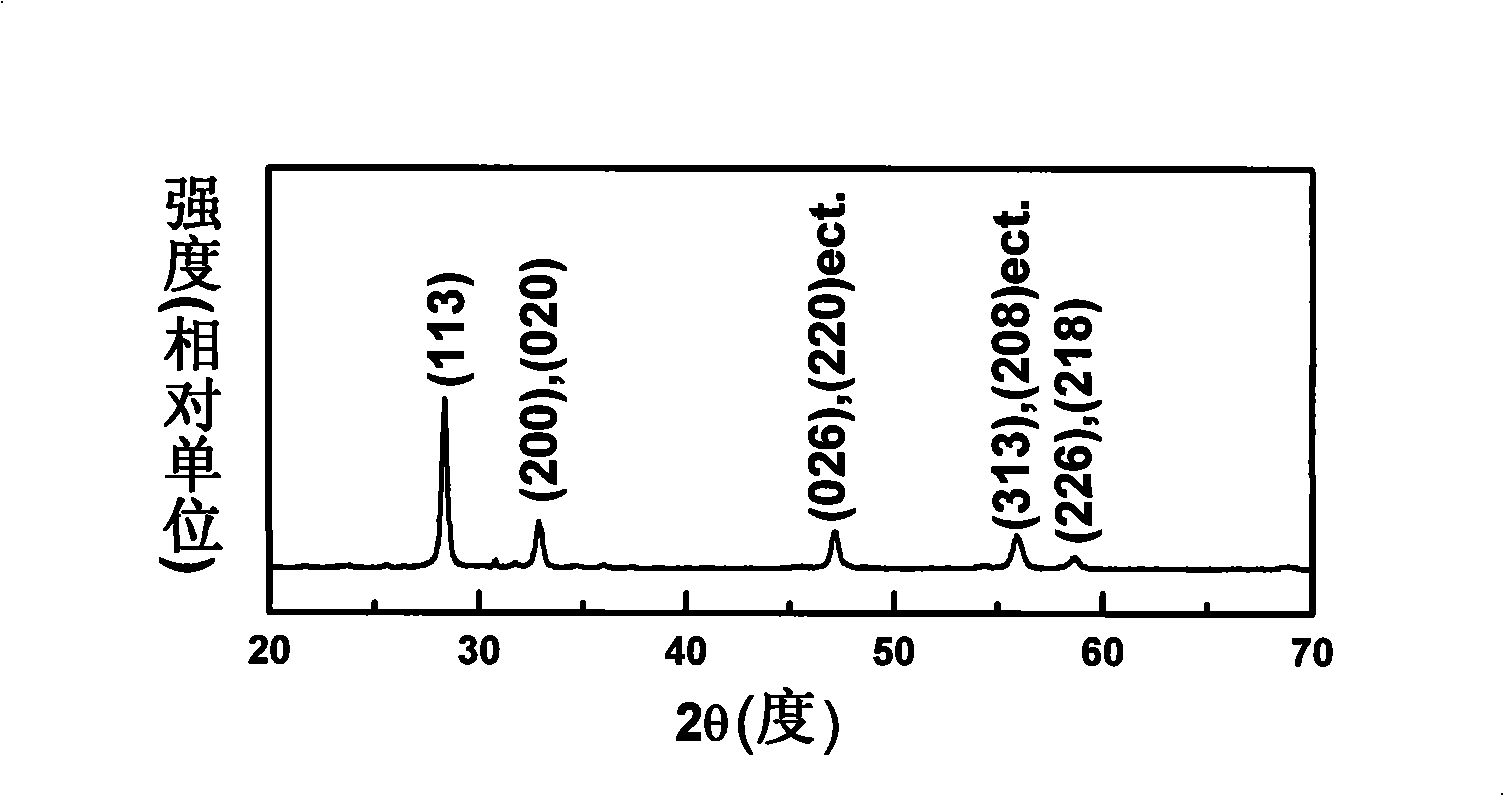

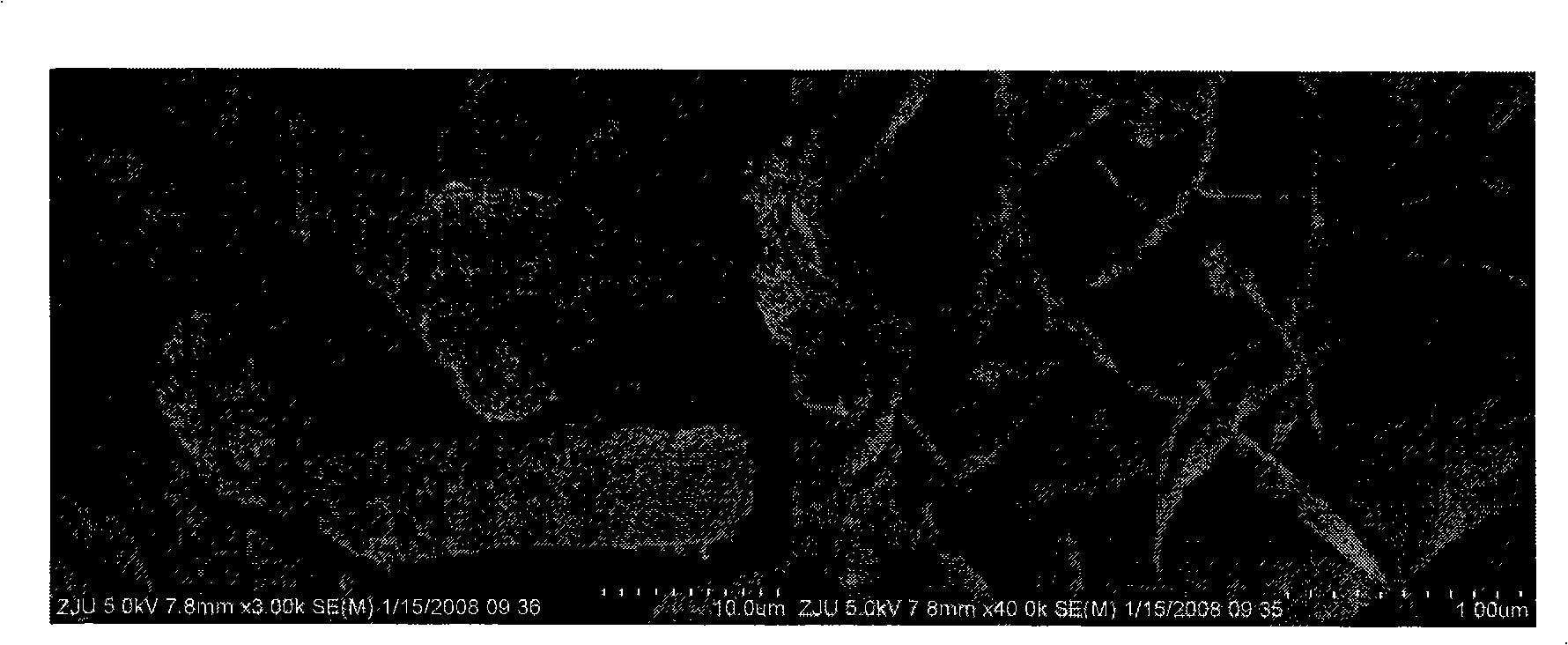

[0021] 4) The obtained solid reaction product was dissolved in hot water, filtered, washed to remove free compounds, and dried at 80°C to obtain visible light-responsive Bi 2 WO 6 catalyst of light. Such as figure 1 , after XRD analysis, it can be seen that the orthorhombic Bi 2 WO ...

Embodiment 2

[0025] 1) take by weighing 40.2g lithium nitrate and the sodium nitrate of 34.24g, mix as reaction medium after;

[0026] 2) According to the weight ratio of reaction medium and oxide raw material 5:1, weigh 1.28g of bismuth oxide and 0.58g of tungsten oxide;

[0027] 3) The reaction medium and the oxide raw material with a weight ratio of 5:1 are added with absolute ethanol, mixed evenly, put into an oven, and dried at 80°C;

[0028] 3) Put the obtained mixture of the reaction medium and the oxide raw material into an alumina crucible, put it into a resistance furnace, raise the temperature to 350° C. at a rate of 3° C. / min, and keep it warm for 8 hours to obtain a solid reaction product;

[0029] 4) The obtained solid reaction product was dissolved in hot water, filtered, washed to remove free compounds, and dried at 80°C to obtain orthorhombic Bi 2 WO 6 catalyst of light. The experimental result of methyl orange degradation by visible light with wavelength λ>400nm is sli...

Embodiment 3

[0031] 1) take by weighing 40.2g lithium nitrate and the sodium nitrate of 34.24g, mix as reaction medium after;

[0032] 2) According to the weight ratio of reaction medium and oxide raw material 20:1, weigh 2.56g of bismuth oxide and 1.16g of tungsten oxide;

[0033] 3) The reaction medium and the oxide raw material with a weight ratio of 20:1 are added with absolute ethanol, mixed evenly, put into an oven, and dried at 80°C;

[0034] 3) Put the obtained mixture of the reaction medium and the oxide raw material into an alumina crucible, put it into a resistance furnace, raise the temperature to 500° C. at a rate of 5° C. / min, and keep it warm for 2 hours to obtain a solid reaction product;

[0035] 4) The obtained solid reaction product was dissolved in hot water, filtered, washed to remove free compounds, and dried at 80°C to obtain orthorhombic Bi 2 WO 6 catalyst of light. The experimental result of methyl orange degradation by visible light with wavelength λ>400nm is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com