Method for preparing high-A113 content high-concentration polymerized aluminum water solution and device thereof

A preparation device and high-concentration technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of unstable product quality in the neutralization method, complex electrodialysis process, and long time consumption, and achieve easy control of process parameters and flocculation The effect of good effect and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

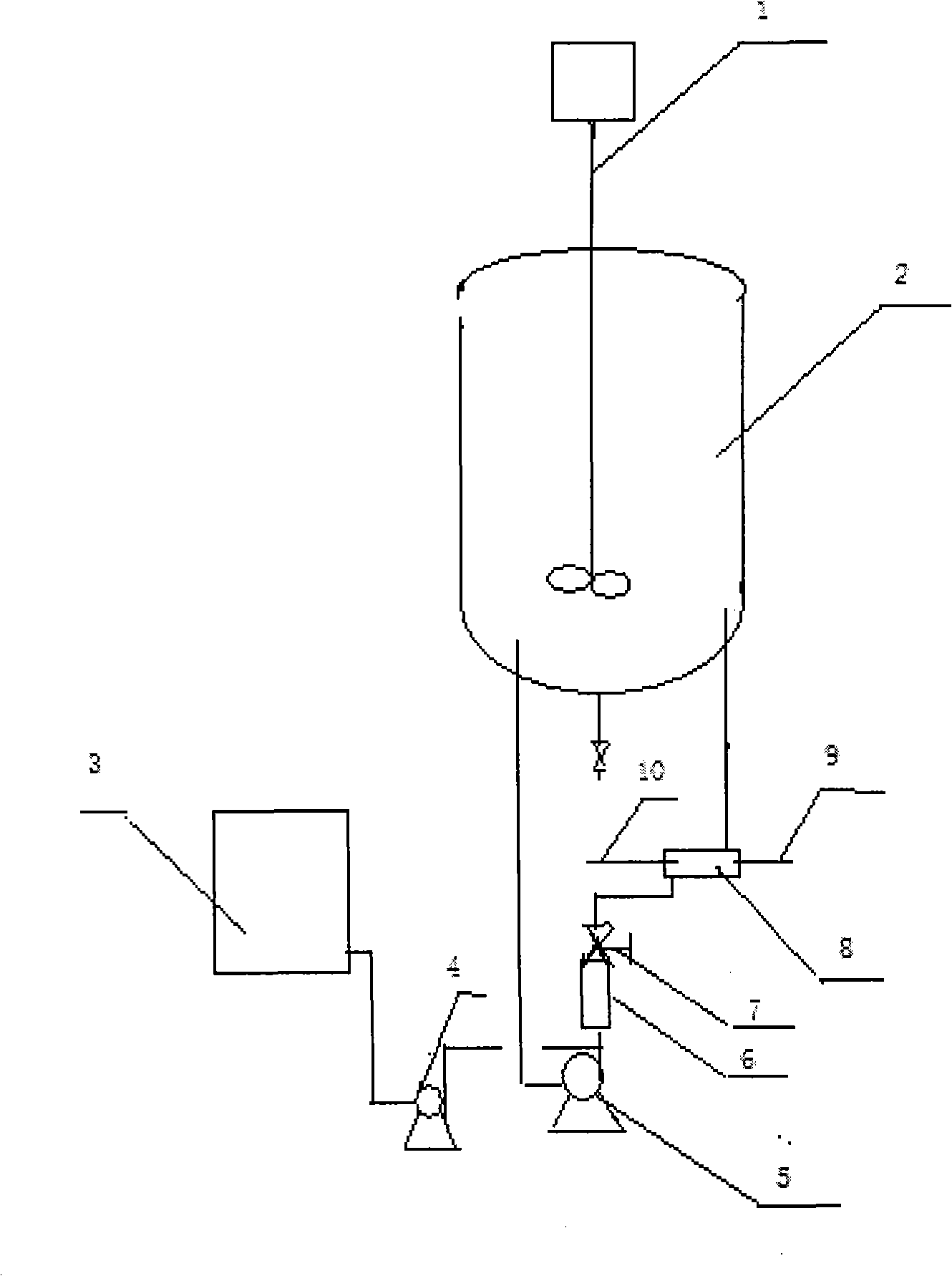

Image

Examples

Embodiment 1

[0014] Example 1: AlCl 3 Prepare a solution with a concentration of 0.5mol / L and a concentration of NaOH of 0.5mol / L, the molar ratio of NaOH to aluminum trichloride is 0.2:1, the reaction temperature is 50°C, the mixing pressure difference is 0.01Mpa, and the ultrasonic intensity is 0.5W / cm2 , the reaction time is 1.5 hours, and the aging time is 5 hours. Aged product Al 13 Content 81%. The industrial sewage of a refinery, the water quality before treatment is: oil 110mg / l, COD 1011mg / l, the above-mentioned flocculant is pumped into the air flotation device, and the addition amount is 30mg / l. The water quality after treatment is 430mg / l COD, 56% removal rate, 31mg / l oil, 72% removal rate. And with commercially available polyaluminum (Al 2 o 3 Content 28%) 30mg / l after treatment, the COD removal rate is only 26%, and the oil removal rate is 36%.

Embodiment 2

[0016] AlCl 3 Prepare a solution with a concentration of 3mol / L and a concentration of NaOH of 5mol / L, the molar ratio of NaOH to aluminum trichloride is 3:1, the reaction temperature is 95°C, the mixing pressure difference is 0.1Mpa, the ultrasonic intensity is 5W / cm2, and the reaction time 10 hours, aging time 24 hours. Aged product Al 13 Content 76%.

[0017] Use this product to treat the oily sewage discharged from the electric desalination device of a refinery. Before treatment, the oil is 510mg / l, COD3210mg / l, suspended matter 330mg / l, and the pump is added to the drainage pipeline, and the amount is 30mg / l. After the sedimentation and separation device, The water quality after treatment is: oil 28mg / l, removal rate 94%, COD 530mg / l, removal rate 80%, suspended matter 18mg / l, removal rate 94.6%.

[0018] This product is used to treat circulating water in a steel mill. Before the treatment, the light transmittance of the circulating water is 30%. Add 30mg / l to implemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com