Novel crushing and separating technique for metal and non-metal in composite material

A composite material, non-metal technology, applied in the field of new pulverization and separation process, can solve the problems of entering the environment, metal and polymer organic substances are difficult to degrade, harm, etc., and achieve the effect of accelerating pulverization and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

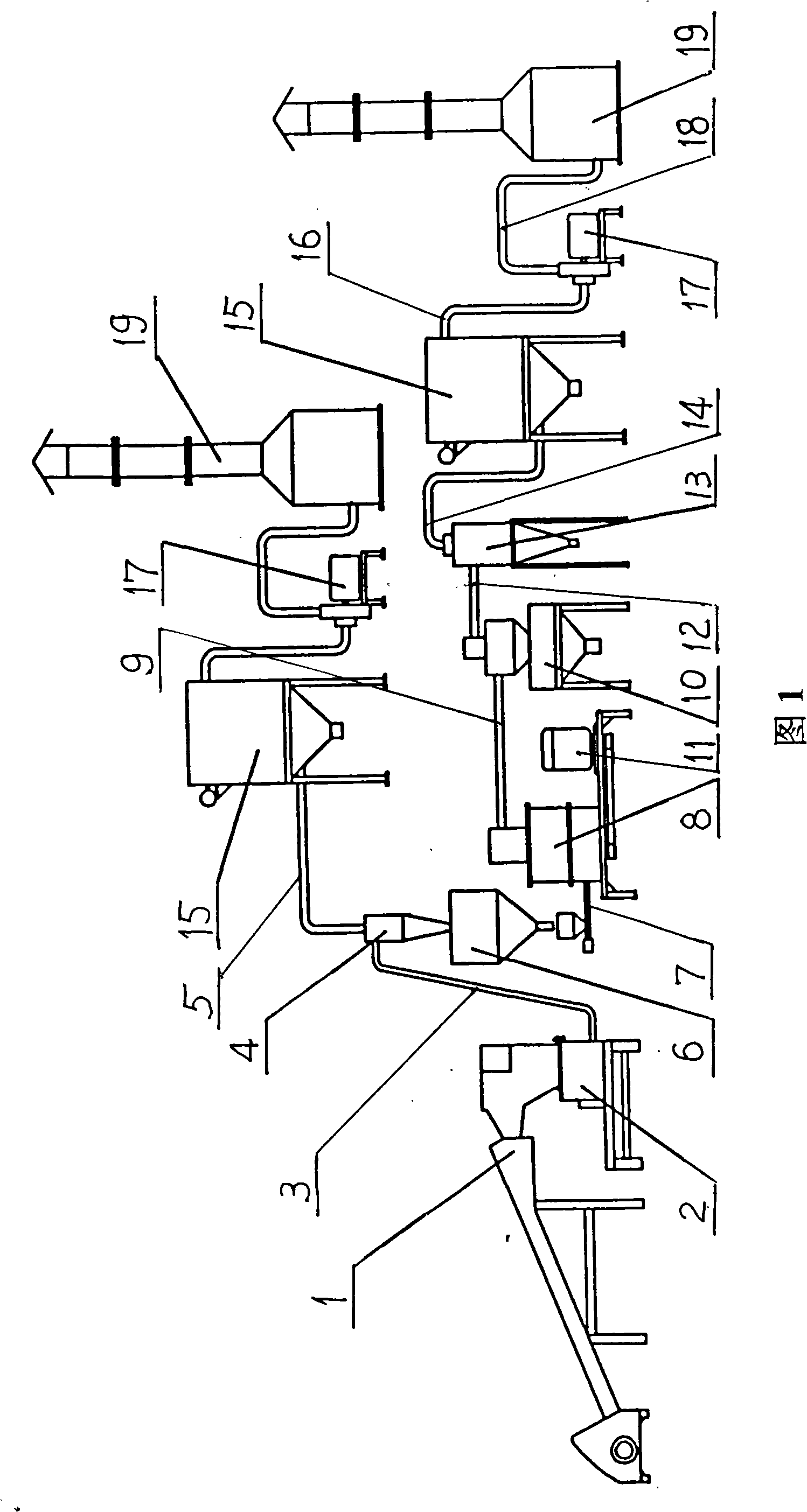

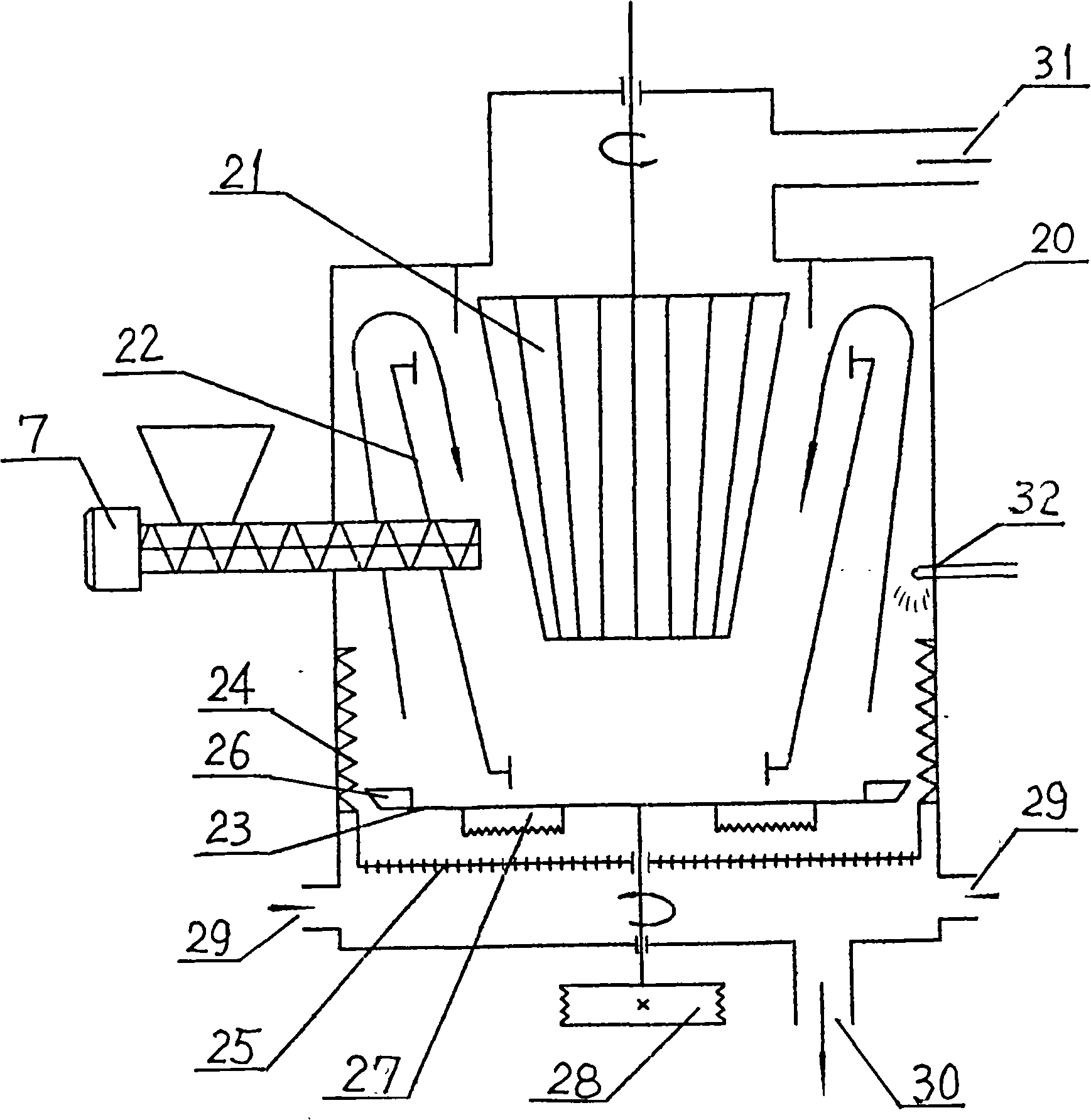

[0028] Referring to Fig. 1, the process of the present invention is that the composite material containing metal and non-metallic substances first enters the powerful crusher 2 through manual or belt conveying device 1 and carries out coarse crushing. The coarse crushed material is sucked into the cyclone separator 4 of the coarse crushing system through the negative pressure of the material conveying pipe 3, and the cyclone separator 4 of the coarse crushing system separates it from solid and gas. The coarse material output from the bottom of the system cyclone separator 4 enters the coarse material bin 6, the bottom outlet of the coarse material bin 6 controls the feeding through the gate valve, and then enters the screw feeder 7, and the screw feeder 7 sends an appropriate amount of coarse material into the crushing and separating host 8. Carry out pulverization and separation. Most of the metal powders with a particle size of less than 2-3mm are recycled from the metal powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com