Method for preparing high purity nano-cerium dioxide with electrolytic method

A nano-cerium dioxide, high-purity technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of low product purity, complex process requirements, and difficult control, and achieve low process conditions, simple equipment and process, and prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

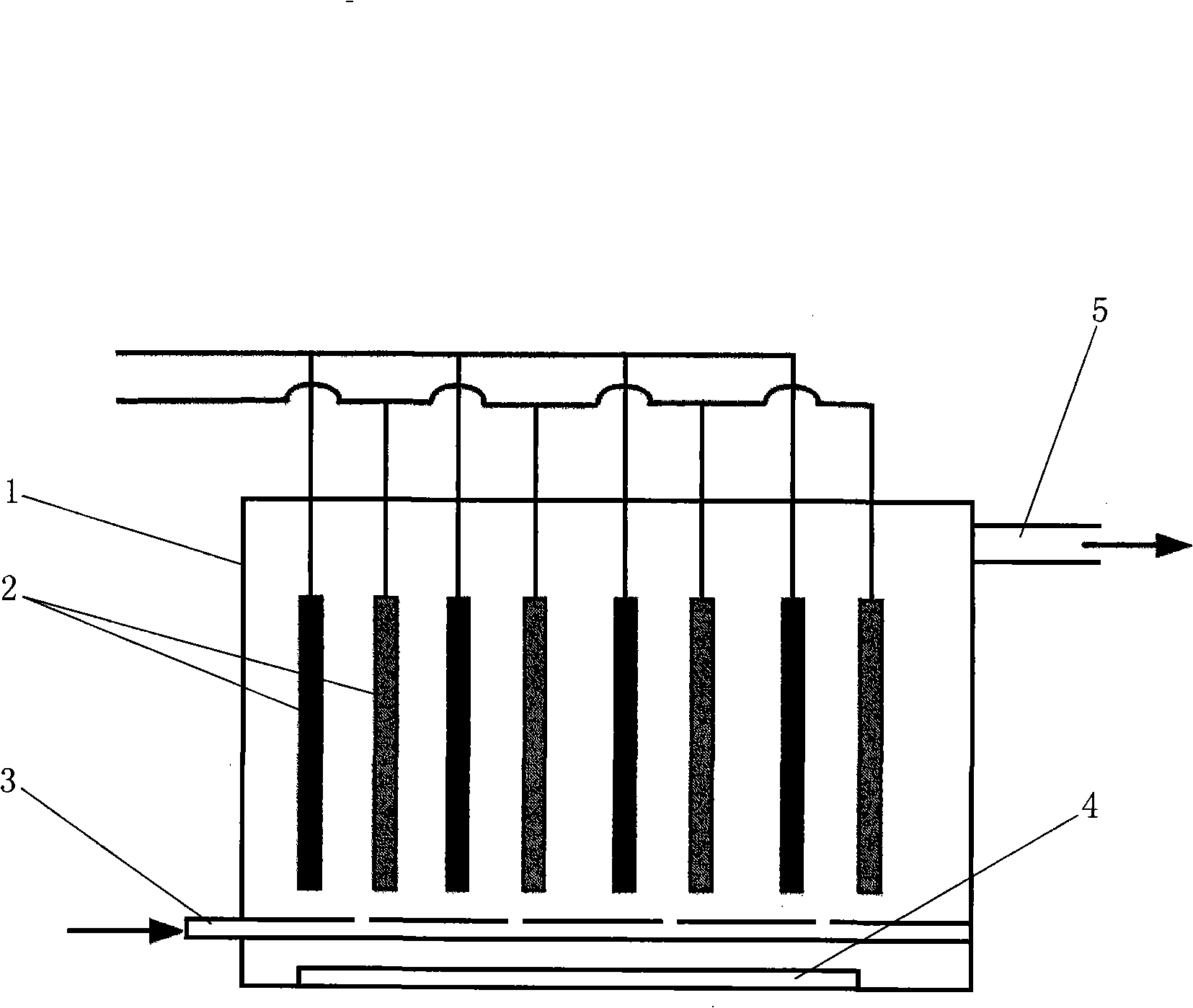

[0032] An electrolysis device for preparing high-purity nano-cerium oxide by electrolysis method includes an electrolysis cell 1, an electrode 2, an air inlet pipe 3, an ultrasonic transmitter 4, and an exhaust pipe 5. Among them, the electrolytic cell 1 adopts a glass electrolytic cell. The size is 200mm×100mm×120mm, the ultrasonic transmitter 4 and the air inlet pipe 3 are installed at the bottom of the electrolytic cell 1, and the exhaust pipe 5 is installed on the top of the electrolytic cell 1. 1.2L of electrolyte is injected into the electrolytic cell 1. The electrolyte is 0.1~2.5 mol / L, purity of 99.95% cerium trichloride solution, both anode and cathode electrodes 2 use titanium-based platinum electrodes, the distance between the plates is 18mm, the transmission frequency of the ultrasonic transmitter 4 is 600KHz, and the power is 60W. During electrolysis, the ultrasonic transmitter 4 is turned on, oxygen enters the electrolytic cell 1 through the air inlet pipe 3, and var...

example 2

[0034] An electrolysis device for preparing high-purity nano-cerium oxide by electrolysis method includes an electrolytic cell 1, an electrode 2, an air inlet pipe 3, an ultrasonic transmitter 4, and an exhaust pipe 5. The electrolytic cell 1 adopts a glass electrolytic cell. The size is 200mm×100mm×120mm, the ultrasonic transmitter 4 and the air inlet pipe 3 are installed at the bottom of the electrolytic cell 1, and the exhaust pipe 5 is installed on the top of the electrolytic cell 1. 1.2L of electrolyte is injected into the electrolytic cell 1. The electrolyte is 0.1~2.5 mol / L, purity of 99.95% cerium trichloride solution, both anode and cathode electrodes 2 use titanium-based platinum electrodes, the distance between the plates is 18mm, the transmission frequency of the ultrasonic transmitter 4 is 800KHz, and the power is 200W. During electrolysis, the ultrasonic transmitter 4 is turned on, oxygen enters the electrolytic cell 1 through the air inlet pipe 3, and various gases ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com