L-beam piezoresistance type micro-accelerometer and production method thereof

An accelerometer and L-shaped beam technology, applied in the field of micro-electronic mechanical systems, can solve the problems of small cross-interference, high sensitivity, low cost, etc., and achieve the effects of suppressing cross-interference, high sensitivity, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

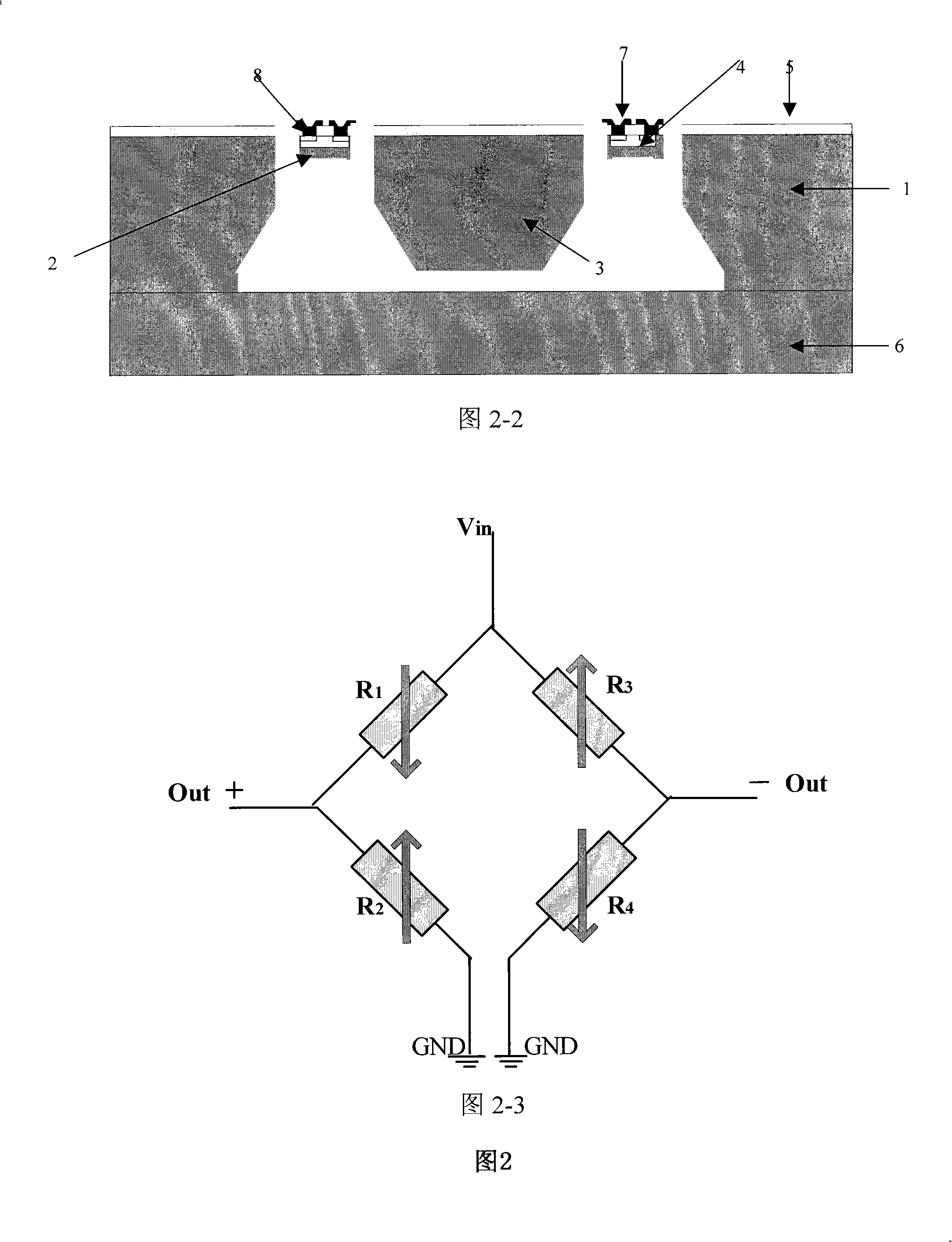

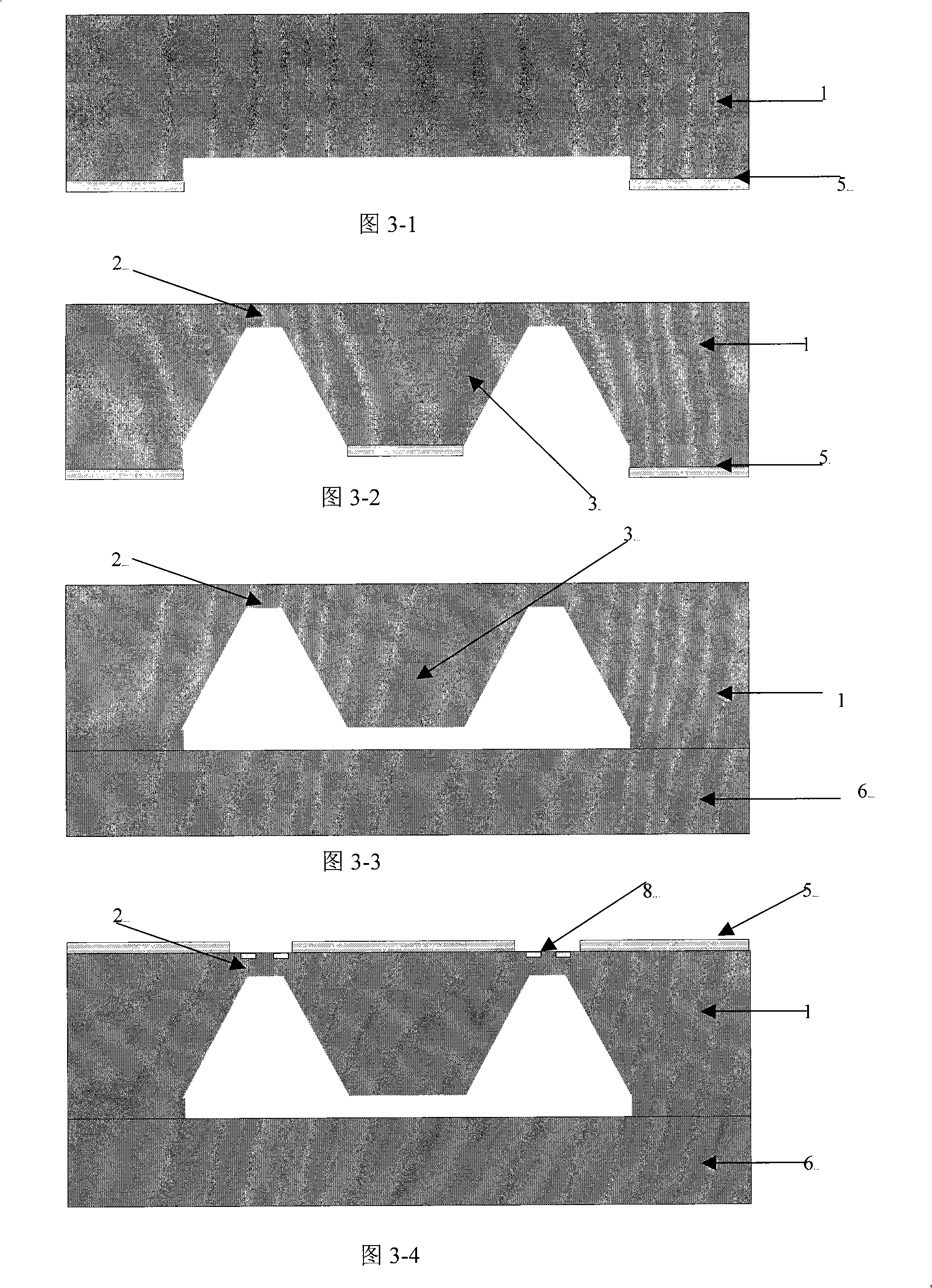

[0033] (1) On the polished silicon wafer 1, first thermally grow the silicon dioxide layer 5, perform front photolithography, and make alignment marks, perform damping gap photolithography on the back side of the silicon wafer, and etch the damping gap by wet etching . See Figure 3-1.

[0034] (2) On the silicon wafer on which the damping gap is formed in step 1, a layer of silicon dioxide is first formed by a thermal oxidation method, photolithography of the mass block 3 is performed, and the mass block structure is etched out with KOH. See Figure 3-2

[0035] (3) Removing the silicon dioxide layer on the mass silicon wafer etched out in step 2, and performing silicon-silicon bonding with another polished silicon wafer as the lower cover plate 6 . See Figure 3-3.

[0036] (4) The silicon wafer after the silicon-silicon bonding in step 3 is oxidized to grow an oxide layer, and the contact hole window 8 is photoetched to implant high-concentration boron ions. See Figure 3-4...

Embodiment 2

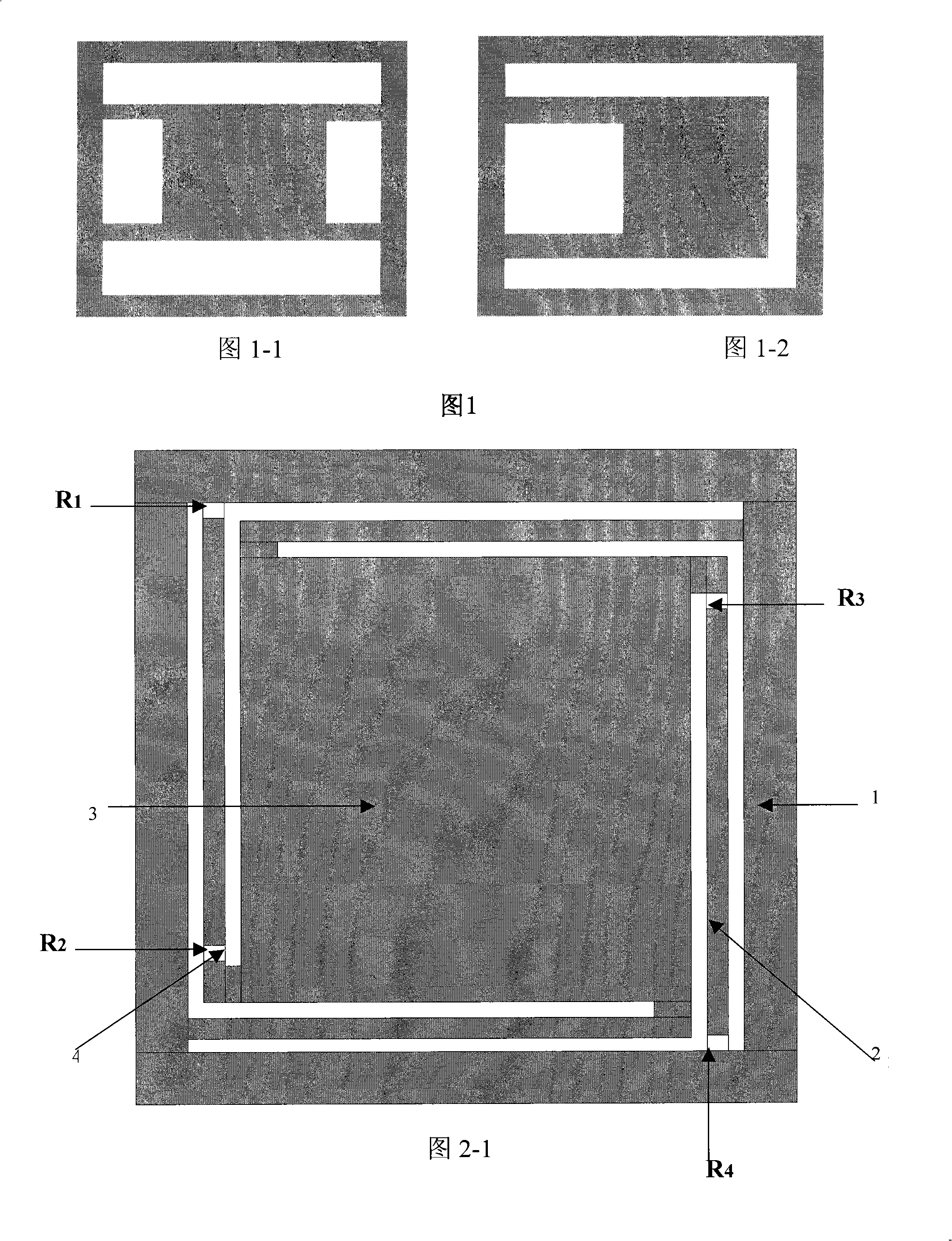

[0044] The specific implementation steps are the same as those in Example 1, the main difference is that in Example 1, when the beam window is photolithographically etched in step 9, only one L-shaped elastic beam is etched at the two opposite corners of the mass block, instead of In Embodiment 1, the beam windows are etched at the four corners of the proof mass, and the rest of the steps are the same as those in Embodiment 1. The top view of the structure of the piezoresistive micro-accelerometer constructed in this embodiment is shown in Figure 4-1.

Embodiment 3

[0046] The specific implementation steps are the same as those in Example 1, the main difference being that when the beam window is photolithographically etched in Step 9 of Example 1, only one L-shaped elastic beam is etched at the two corners of the same side of the mass block, Instead of etching beam windows at the four corners of the mass block in Example 1, the rest of the steps are the same as those in Example 1. The top view of the piezoresistive micro-accelerometer structure constructed in this example is shown in Fig. 4-2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com