Capacitor type microphone chip

A condenser microphone and chip technology, applied in the field of microphones, can solve the problems of adhesion between the diaphragm and the back pole, increase the strength of the back pole, increase the process steps, etc., so as to reduce the adhesion between the diaphragm and the back pole, improve the yield, cantilever Soft structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

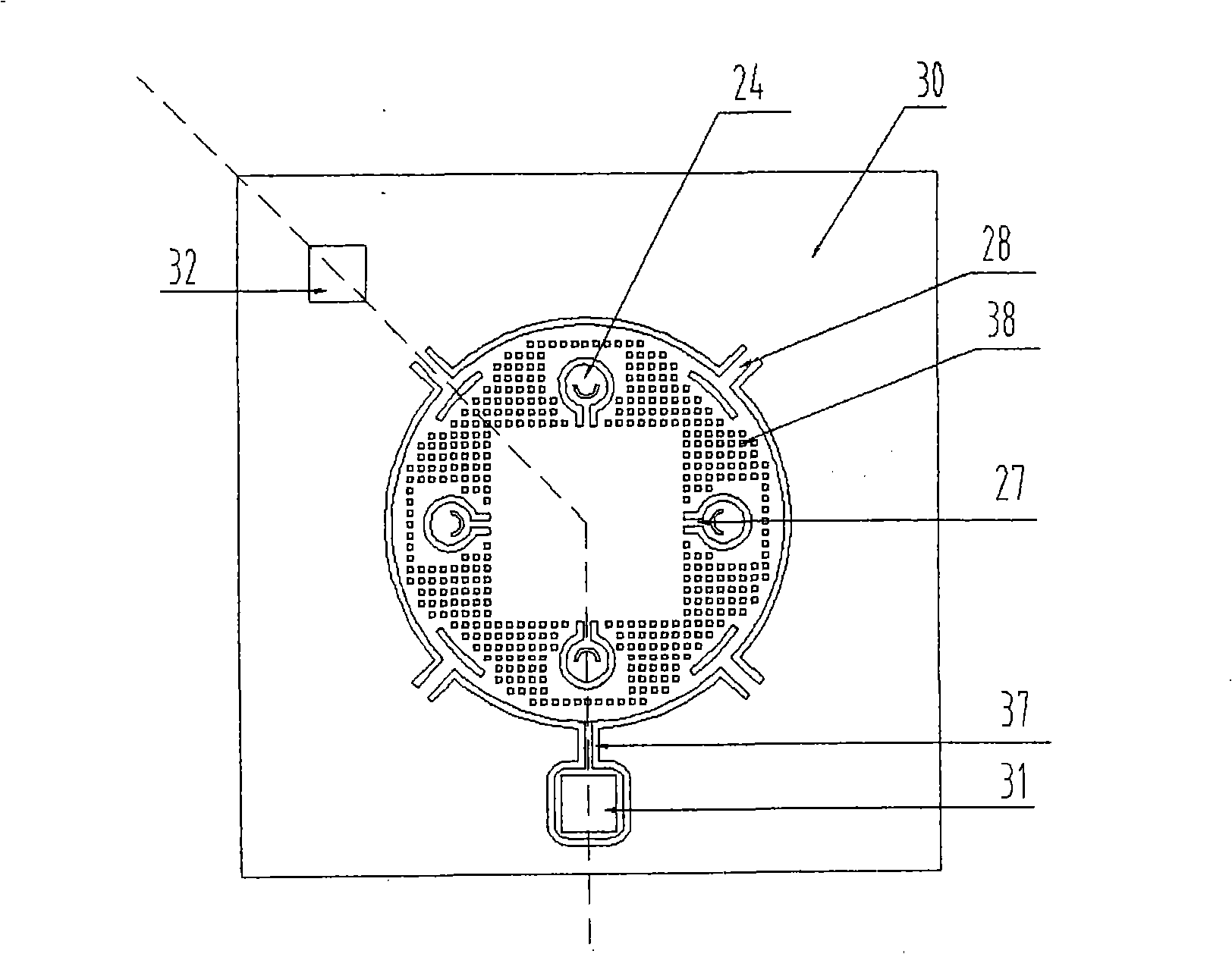

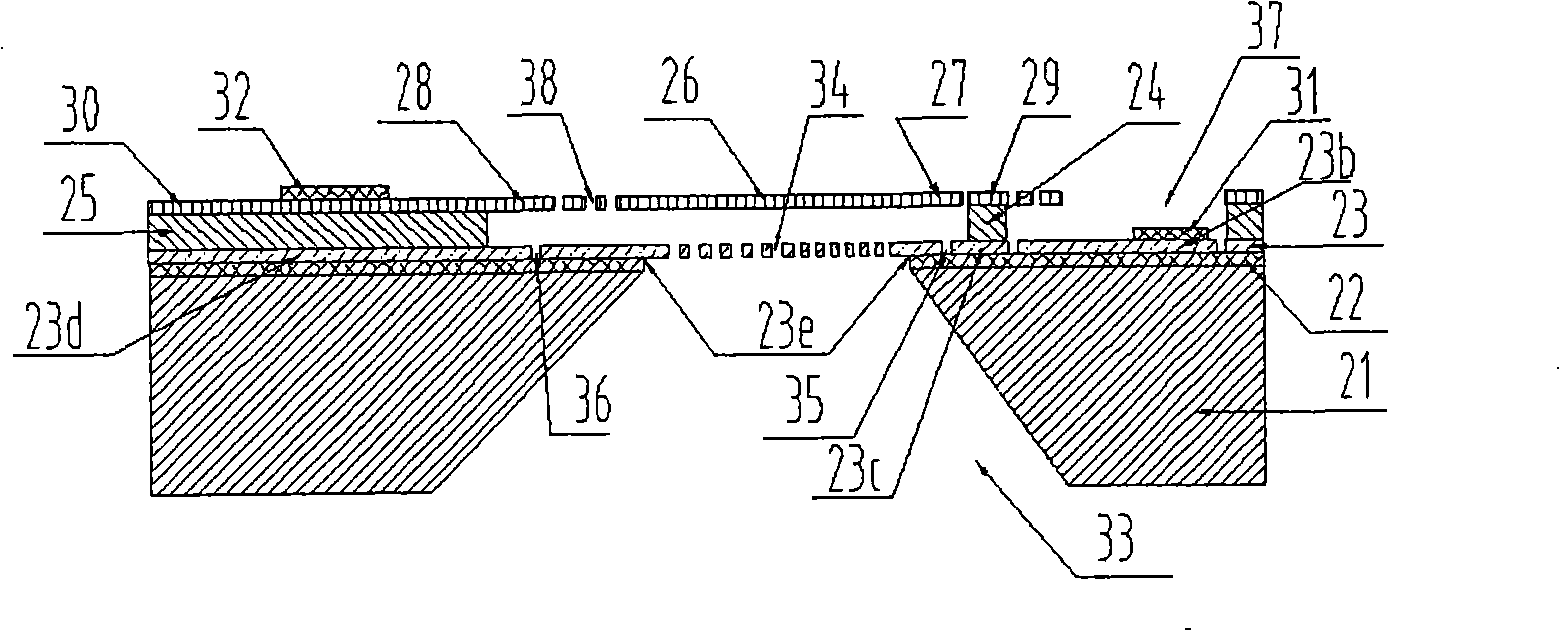

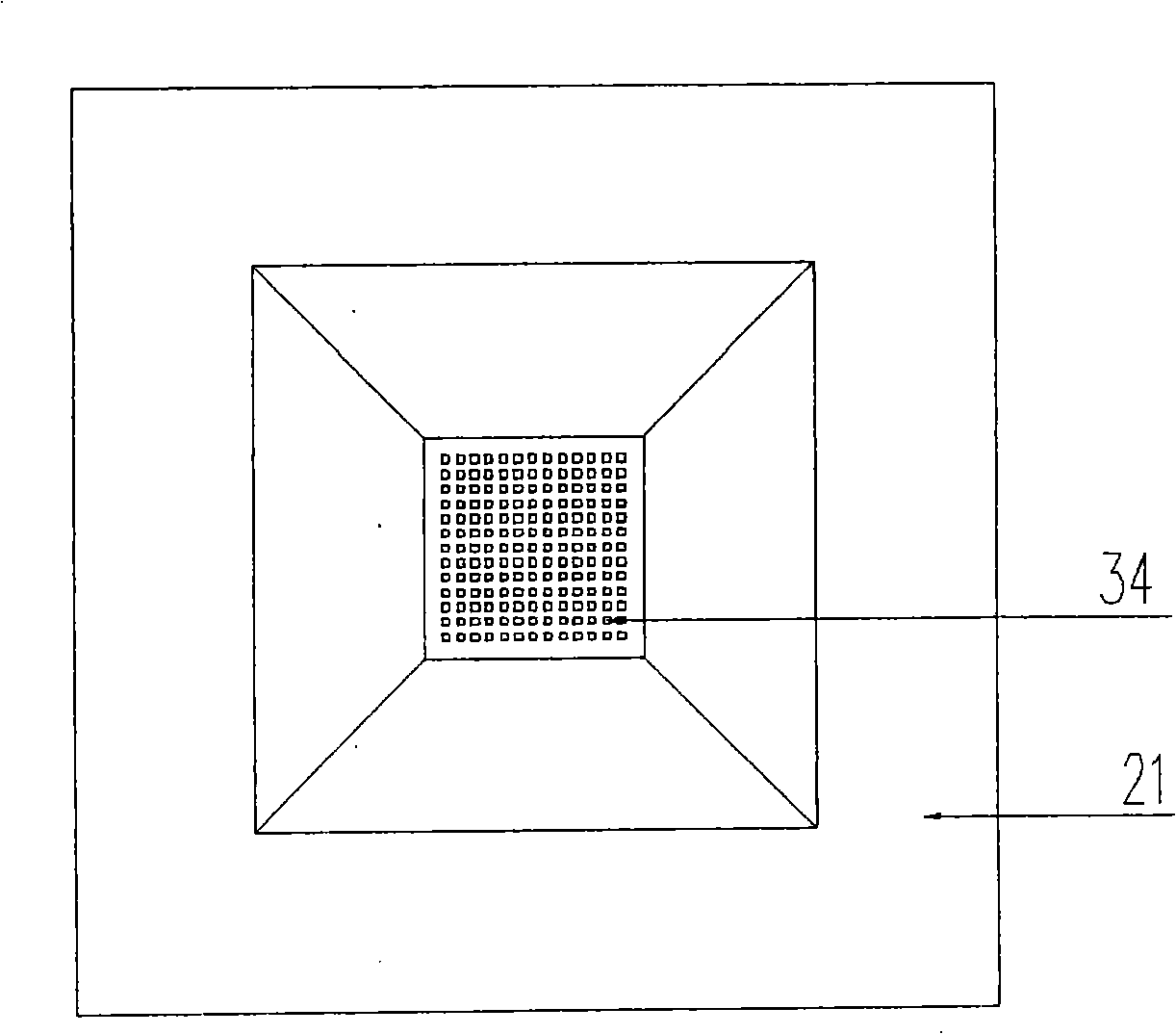

[0061] Such as Figure 1-14 Shown is the first embodiment of the present invention, which is the planar composite cantilever capacitive microphone chip structure of the present invention, as figure 1 , figure 2 As shown, its feature is that the diaphragm is supported by a planar composite suspension beam structure composed of inner suspension beams and outer suspension beams, and only the central part of the back pole is suspended in the air. From bottom to top: base 21, insulating layer 22, conductive layer 23, and inner suspension beam support 24 , an outer cantilever beam support 25, a diaphragm 26, an inner cantilever beam 27, an outer cantilever beam 28, an inner cantilever beam frame 29, an outer cantilever beam frame 30, and a lower electrode 31 and an upper electrode 32.

[0062] Wherein, there is a through hole in the center of the base 21 and the insulating layer 22 , which is the back cavity 33 . The substrate 21 is a semiconductor material, which can be silicon,...

Embodiment 2

[0071] Such as Figure 15-22 Shown is the first embodiment of the present invention, which is the chip structure of the three-dimensional composite suspension beam capacitive microphone of the present invention, as Figure 15 , Figure 16 As shown in the figure, it is characterized in that the diaphragm is supported by a three-dimensional suspension beam structure through the upper suspension beam and the lower suspension beam; only the central part of the back pole is suspended. From bottom to top: base 21, insulating layer 22, conductive layer 23, lower cantilever beam support 24, upper cantilever beam support 25, diaphragm 26, upper cantilever beam 28, upper cantilever beam frame 30, and lower electrode 31, upper electrode 32 .

[0072] Wherein, there is a through hole in the center of the base 21 and the insulating layer 22 , which is the back cavity 33 . The substrate 21 is a semiconductor material, which can be silicon, and the back cavity 33 at the center of the silico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com