Treating method for organic refuse and special equipment therefor

A treatment method and organic waste technology, applied in the direction of organic fertilizer, pyrolysis treatment sludge, application, etc., can solve the problems of polluting the surrounding environment, garbage pollution, serious accumulation pollution, etc., and achieve low operating costs, fast processing speed, and adaptability wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

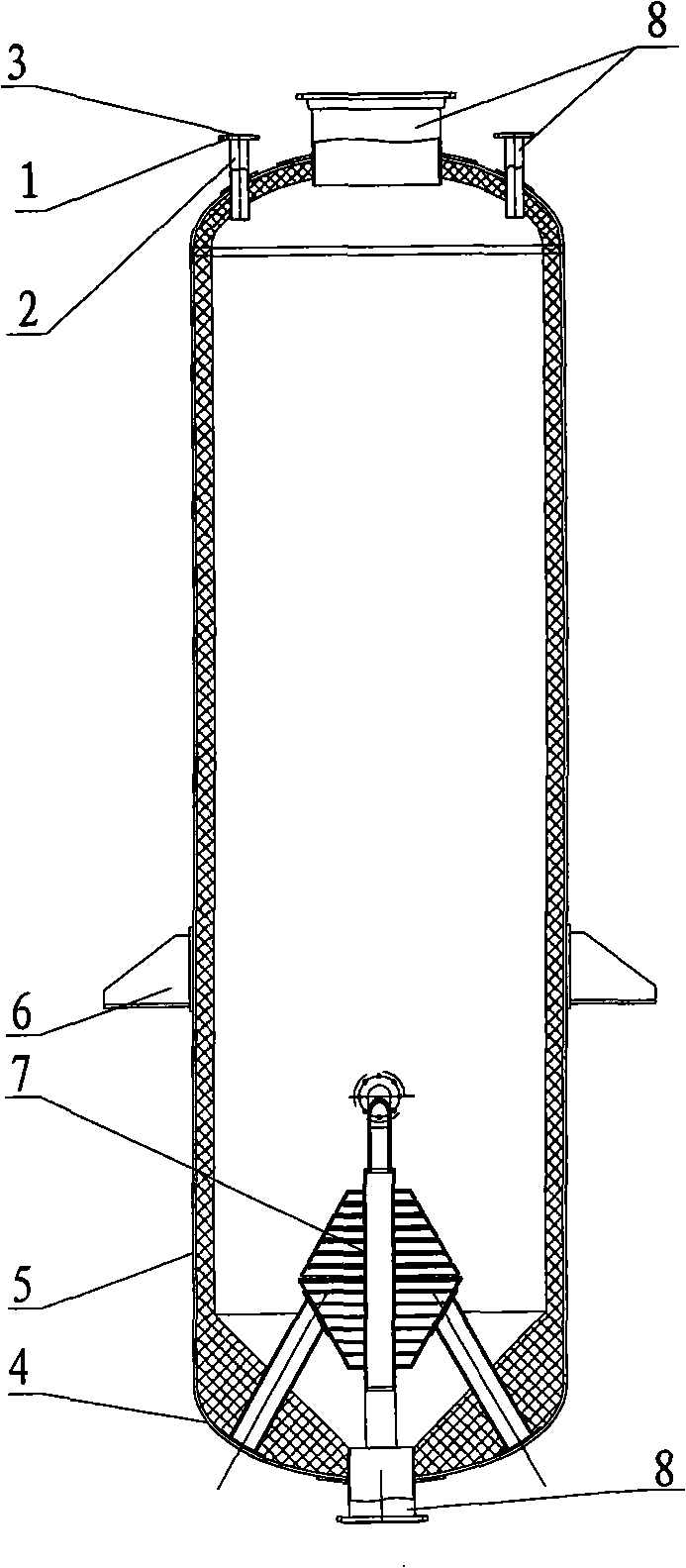

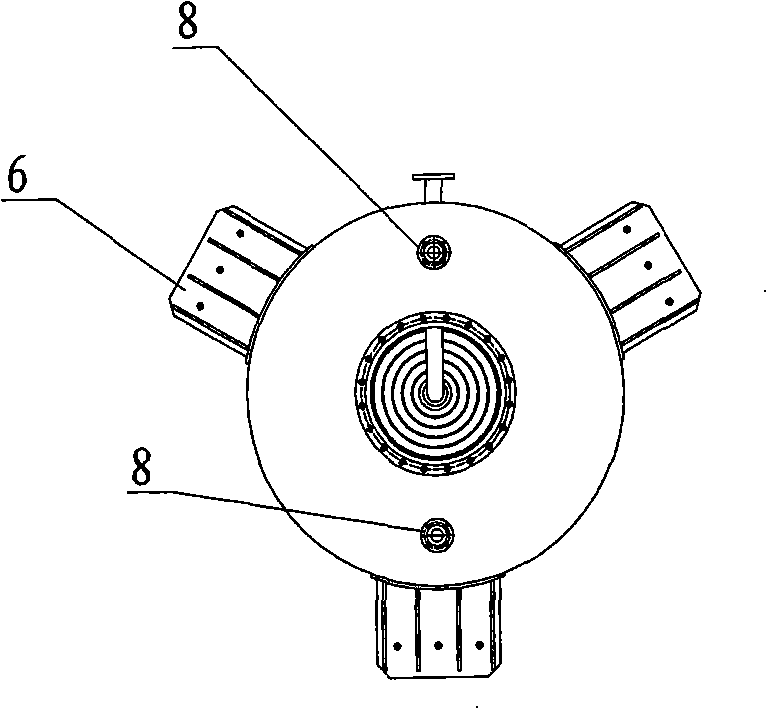

[0038] The specific embodiment is described below in conjunction with accompanying drawing:

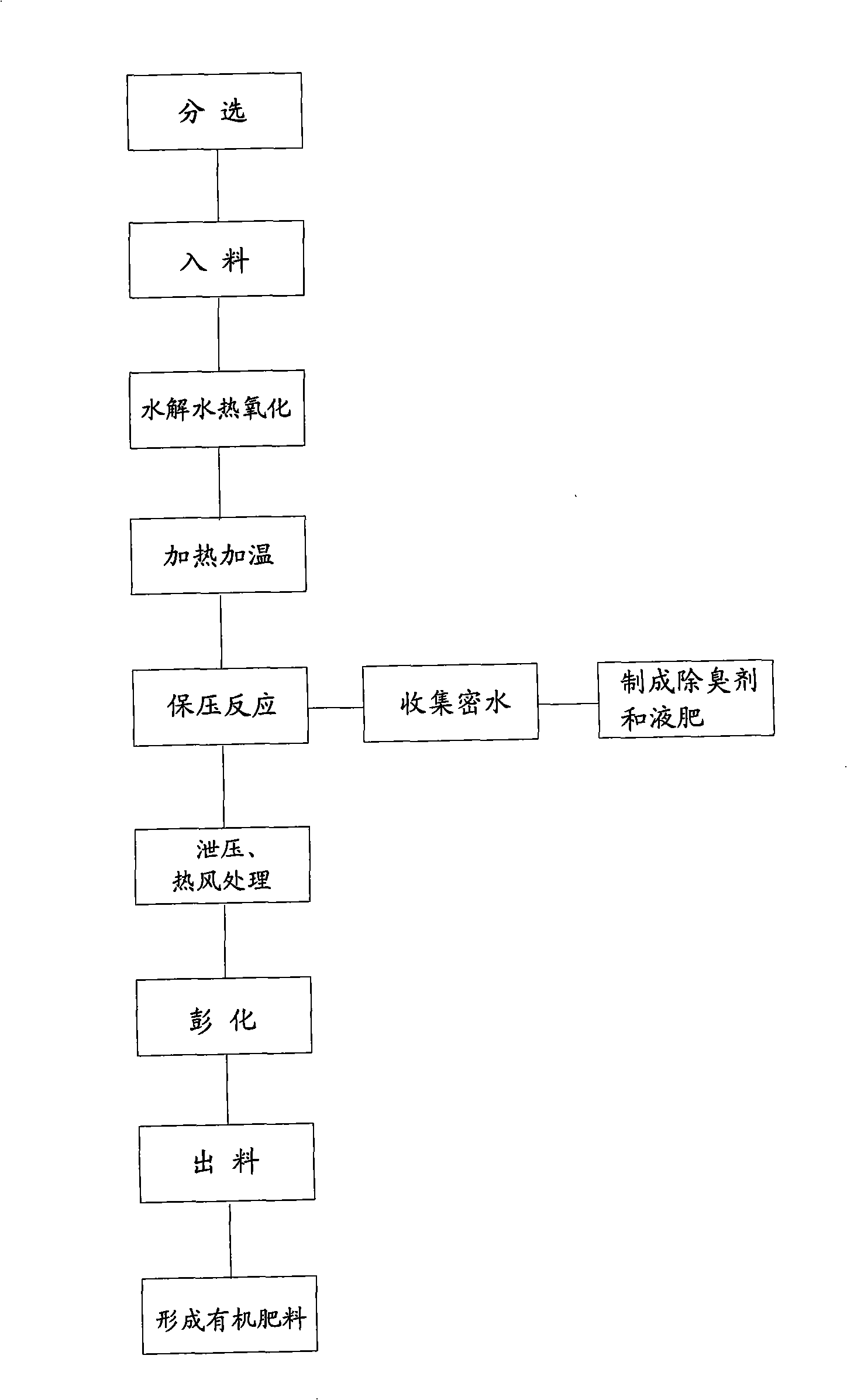

[0039] Such as figure 1 As shown, when the organic waste sorted out from municipal solid waste enters the silo, 15% concentration of dilute acid is sprayed into it at the same time according to the ratio of 1% of the dry basis weight of the material, so that the material and dilute acid are mixed, and the preheating valve is opened at the same time , using boiler exhaust gas or hydrolysis hydrothermal oxidation kettle exhaust gas to fully preheat the material. The preheated organic matter goes to the hydrolysis hydrothermal oxidation kettle through the discharge machine and the hoist. When the organic matter material enters the hydrolysis hydrothermal oxidation kettle, 15% concentration of dilute acid is sprayed into it at the same time according to the ratio of 1% of the dry weight of the material. When the volume of the material reaches 90% of the volume of the hydrolytic hydrother...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com