Preparation of Fe5(PO4)4(OH)3 and application thereof

A reaction kettle and post-reaction technology, which is applied in the field of electrochemistry, can solve problems such as difficult deintercalation, inconspicuous effect, and low capacity, and achieve the effects of reduced preparation cost, outstanding high temperature stability, and short synthesis cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) Weigh 0.399g Fe 2 (SO 4 ) 3 , 0.098g H 3 PO 4 and 0.042g LiOH·H 2 O (molar ratio Li:Fe:PO 4 3+ =1:2:1), the H 3 PO 4 Add in 200ml steel reactor, and add 50ml distilled water, then Fe 2 (SO 4 ) 3 Add to the reaction kettle, and keep stirring, then add LiOH·H 2 0, the pH of the solution was recorded to be about 2 at this time, and the color of the solution was white and yellowish, and the reaction kettle was sealed;

[0022] 2) Control the heating rate to about 10°C / min, raise the temperature of the reactor to 220°C, and keep it warm for 2 hours;

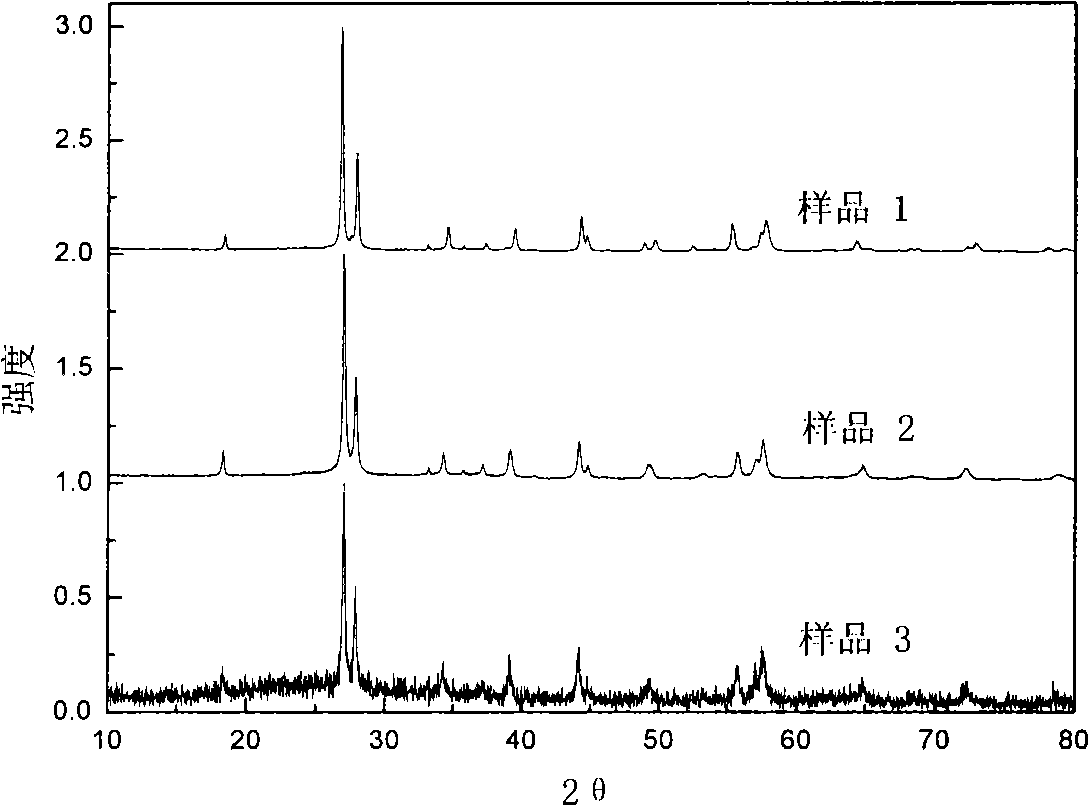

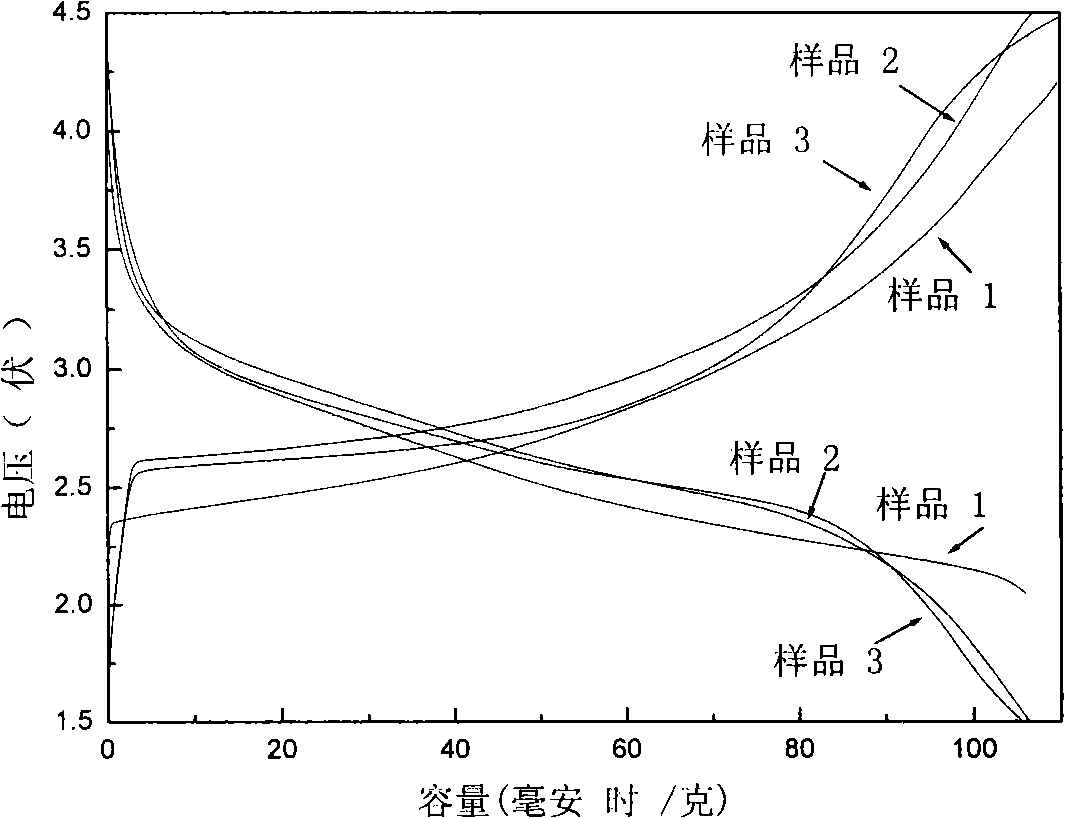

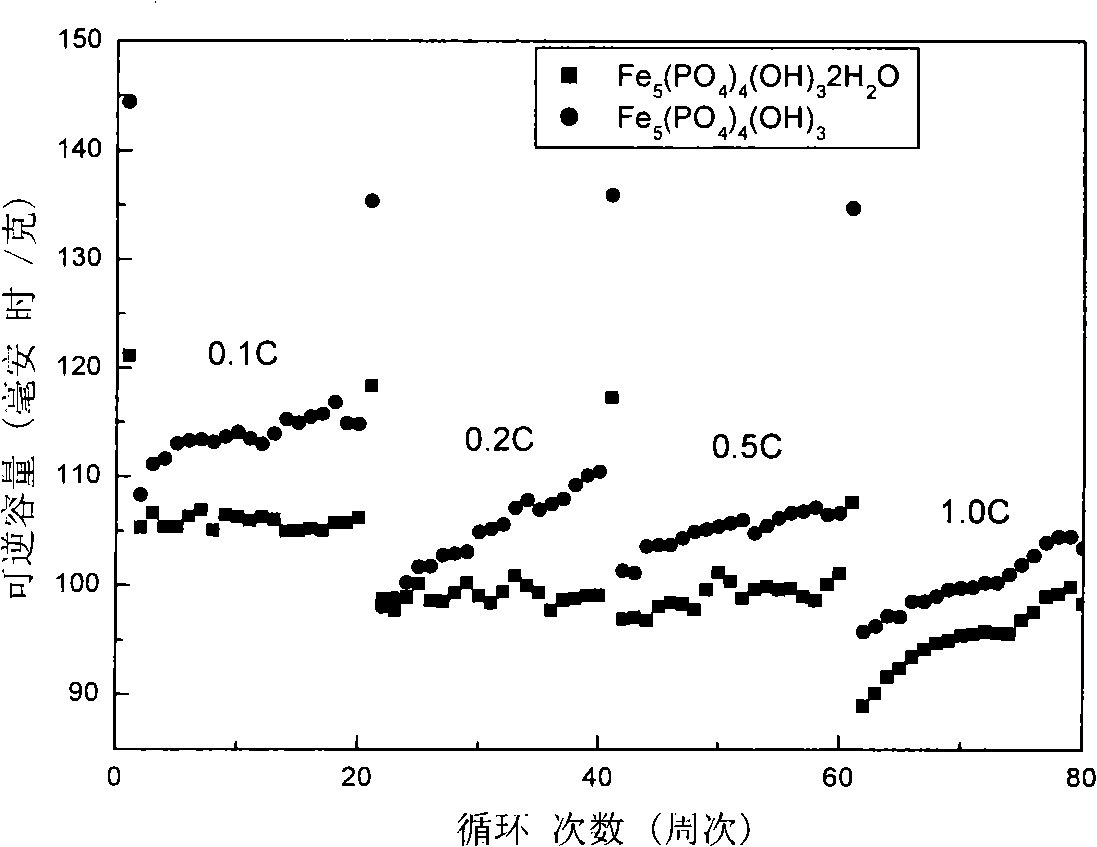

[0023] 3) The resulting product solution was washed and clarified with distilled water, and placed in a vacuum oven at 80° C. for 2 hours after suction filtration to obtain the dark green product Fe 5 (PO 4 ) 4 (OH) 3 2H 2 O;

[0024] 4) Fe 5 (PO 4 ) 4 (OH) 3 2H 2 O to N 2 Under protective conditions, heat preservation at 400°C for 5 hours to prepare the lithium ion battery cathode material Fe 5 (PO ...

Embodiment 2

[0027] 1) Weigh 1.9994g Fe 2 (SO 4 ) 3 , 0.49g H 3 PO 4 and 0.2098g LiOH·H 2 O (molar ratio Li:Fe:PO 4 3+ =1:2:1), the Fe 2 (SO 4 ) 3 Add 200ml steel reaction kettle, and add 80ml distilled water, then add H 3 PO 4 Add to the reaction kettle, keep stirring, then add LiOH·H 2 0, the pH of the solution was recorded to be about 1.9 at this time, and the color of the solution was white and yellowish, and the reaction kettle was sealed;

[0028] 2) Control the heating rate to about 8°C / min, raise the temperature of the reactor to 200°C, and keep it warm for 1.5 hours;

[0029] 3) The resulting product solution was washed and clarified with distilled water, and placed in a vacuum oven at 120° C. for 1 hour after suction filtration to obtain the dark green product Fe 5 (PO 4 ) 4 (OH) 32H 2 O;

[0030] 4) Fe 5 (PO 4 ) 4 (OH) 3 2H 2 O to N 2 Under protective conditions, after holding at 450°C for 3 hours, the lithium-ion battery cathode material Fe 5 (PO 4 ) ...

Embodiment 3

[0033] 1) Weigh the reactant 0.399g Fe 2 (SO 4 ) 3 , 0.098g H 3 PO 4 and 0.042g LiOH·H 2 O (molar ratio Li:Fe:PO 4 3+ =1:2:1), the H 3 PO 4 Add in 200ml steel reaction kettle, and add 60ml distilled water, then Fe 2 (SO 4 ) 3 Add to the reaction kettle, keep stirring, then add LiOH·H 2 0, the pH of the solution measured at this moment was about 2.0, and the color of the solution was white and yellowish, and the reaction kettle was sealed;

[0034] 2) Control the heating rate to about 12°C / min, raise the temperature of the reactor to 210°C, and keep it warm for 2.5 hours;

[0035] 3) The resulting product solution was washed and clarified with distilled water several times, and then placed in a vacuum oven at 100°C for 2 hours after suction filtration to obtain the dark green product Fe 5 (PO 4 ) 4 (OH) 3 2H 2 O;

[0036] 4) Fe 5 (PO 4 ) 4 (OH) 3 2H 2 O to N 2 Under protective conditions, after holding at 350°C for 4 hours, the lithium-ion battery cathod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com