Novel kation gemini surfactant and process for synthesizing the same

A gemini surface and cationic technology, applied in chemical instruments and methods, dissolution, chemical/physical processes, etc., can solve the problems of limited varieties of gemini surfactants, difficulty in realizing industrial production, and low yield in the preparation process, and achieve low price , good stability and excellent surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 Urethane reaction

[0028] At room temperature (25°C), in a 250ml three-necked round-bottomed flask, add 17.5ml of solvent acetone, dropwise add 5ml of N,N-dimethylethanolamine, mix well, and slowly add an appropriate amount of 2,4-toluene diisocyanate ( TDI) 3.55ml (the molar weight is half of that of alkanolamine). After sealing, let it stand, and react at room temperature for 6 hours. The product is a light yellow liquid with a slight viscosity.

Embodiment 2

[0029] The synthesis of embodiment 2 BG07

[0030] Take the synthesis of BG07-14 as an example. Put the above-mentioned round-bottomed flask into a water bath, and add 12.5 ml of n-tetradecyl bromide (the same molar amount as dimethylethanolamine) dropwise under stirring conditions. Seal and stir, keep the temperature at 45°C, and react for 12 hours to obtain a high-viscosity yellow-brown liquid. Dry at 80°C to obtain a yellow solid, which is BG07-14, weighing 21.4158-22.0544g (yield: 95-98%).

Embodiment 3

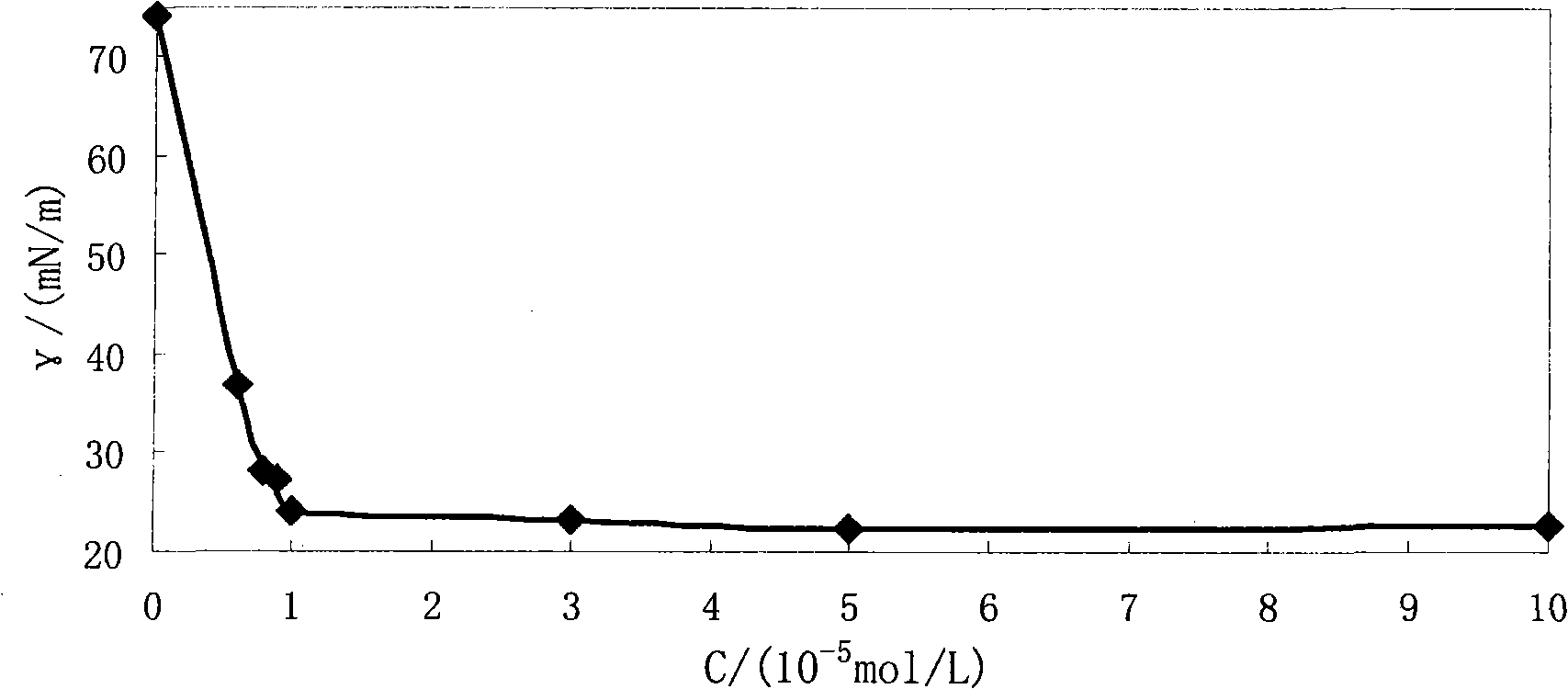

[0031] The surface activity measurement of embodiment 3 BG07 series surfactants

[0032] Taking the surface activity determination of BG07-14 as an example, image 3 . The critical surface tension of BG07-14 (γ cmc ) is 21.9mN·m -1 , with a critical micelle concentration of 1.0×10 -5 mol L -1 . With common surfactants (such as dodecyltrimethylammonium bromide cmc is 1.6×10 -2 mol L -1 , gamma cmc 40mN·m -1 ) compared to its surface activity is greatly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com