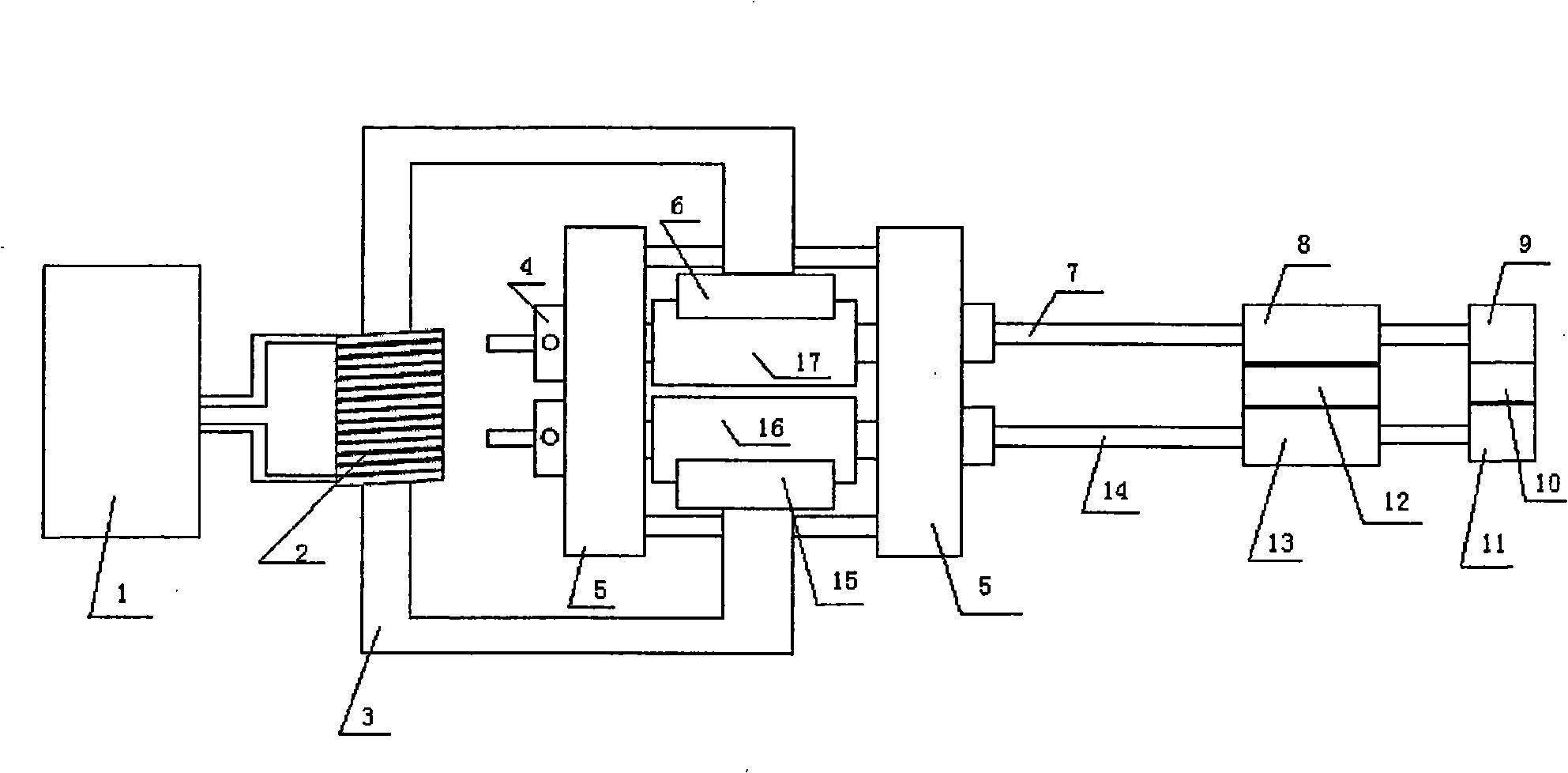

Magnetostatic field twin roller caster

A twin-roll casting mill and static magnetic field technology, applied in the direction of metal rolling stands, metal rolling mill stands, rolls, etc., can solve the problems of strength and plasticity decline, uneven alloy structure, etc., and achieve the effect of good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

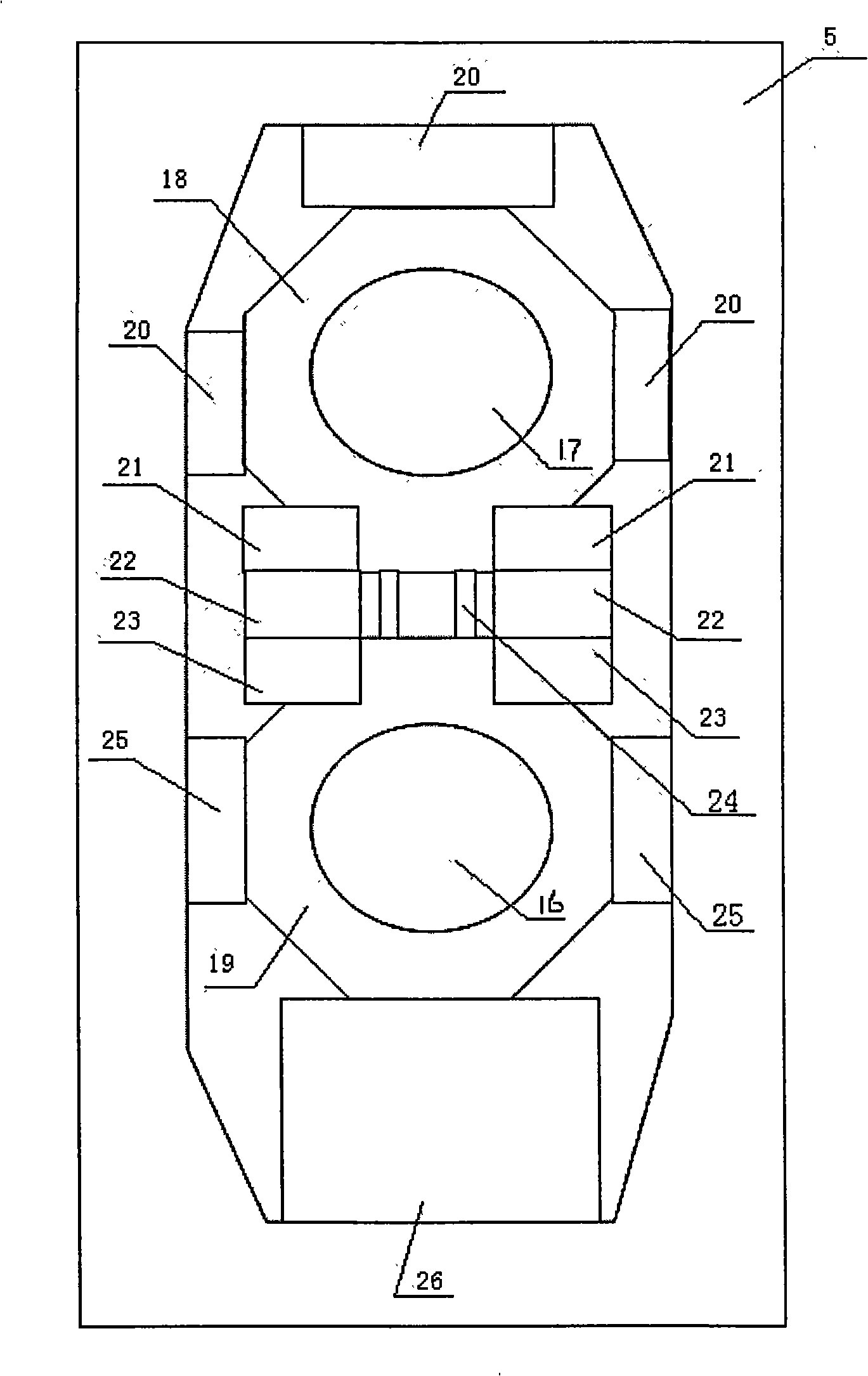

example 1

[0020] When producing aluminum and aluminum alloys, the casting roll is made of gun steel. The diameter of the casting roll is 500 mm. It is driven by two separate 15-kilowatt motors. The two transmission parts are installed separately with magnetic isolation materials. Among them, the bearing of the upper roll is used around The magnetic isolation treatment is performed between brass or 1Cr18Ni9Ti stainless steel and the archway, the coil is applied with a DC current of 600 amperes, the number of turns of the excitation coil is 300, the outer diameter of the copper tube is 10mm, the static magnetic field strength between the roll gaps is 0.5 Tesla, magnesium alloy The grade is AZ61, the melt pouring temperature is 700~720℃, the cooling water temperature is 15℃, the casting speed is 0.8~1.2m / min, the roll gap of the casting roll is 5mm, the length of the casting zone is 60mm, and the nozzle is melted inside. The body height is 100 mm.

example 2

[0022] In the production of magnesium and magnesium alloys, the casting roll is made of gun steel. The diameter of the casting roll is 500 mm. It is driven by two separate 15-kilowatt motors. The two transmission parts are installed separately with magnetic isolation materials. The upper roller is surrounded by bearings. The magnetic isolation treatment is performed between brass or 1Cr18Ni9Ti stainless steel and the archway. The DC current applied to the coil is 800 amperes, the number of turns of the excitation coil is 600, the outer diameter of the copper tube is 12mm, the static magnetic field strength between the roll gap is 0.5 Tesla, and the magnesium alloy The grade is AZ61, the melt pouring temperature is 720℃, the cooling water temperature is 15℃, the casting speed is 3~4m / min, the roll gap of the casting roll is 5mm, the length of the casting zone is 60mm, and the height of the melt in the nozzle is 100 mm, Ar gas protection is used in the melt pouring process.

example 3

[0024] In the production of copper and copper alloys, the casting roll is made of gun steel. The diameter of the casting roll is 500 mm. It is driven by two separate 15-kilowatt motors. The two transmission parts are separately installed with magnetic isolation materials. The upper roll is surrounded by bearings. The magnetic isolation treatment is performed between brass or 1Cr18Ni9Ti stainless steel and the archway, the coil is applied with a DC current of 600 amperes, the number of turns of the excitation coil is 500, the outer diameter of the copper tube is 11mm, the static magnetic field strength between the roll gaps is 0.5 Tesla, magnesium alloy The grade is AZ61, the melt pouring temperature is 700~720℃, the cooling water temperature is 15℃, the casting speed is 2~3m / min, the roll gap of the casting roll is 5mm, the length of the casting zone is 60mm, the melt in the mouth The height is 100 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com