Method for installing generator rotor guard ring block type insulation barrel

A technology of generator rotor and installation method, applied in laying solid insulation and other directions, can solve the problems of complex processing and manufacturing of insulating cylinders, disjointed production, difficult maintenance, etc., and achieves the effects of reliable operation, simple assembly, and reduced production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

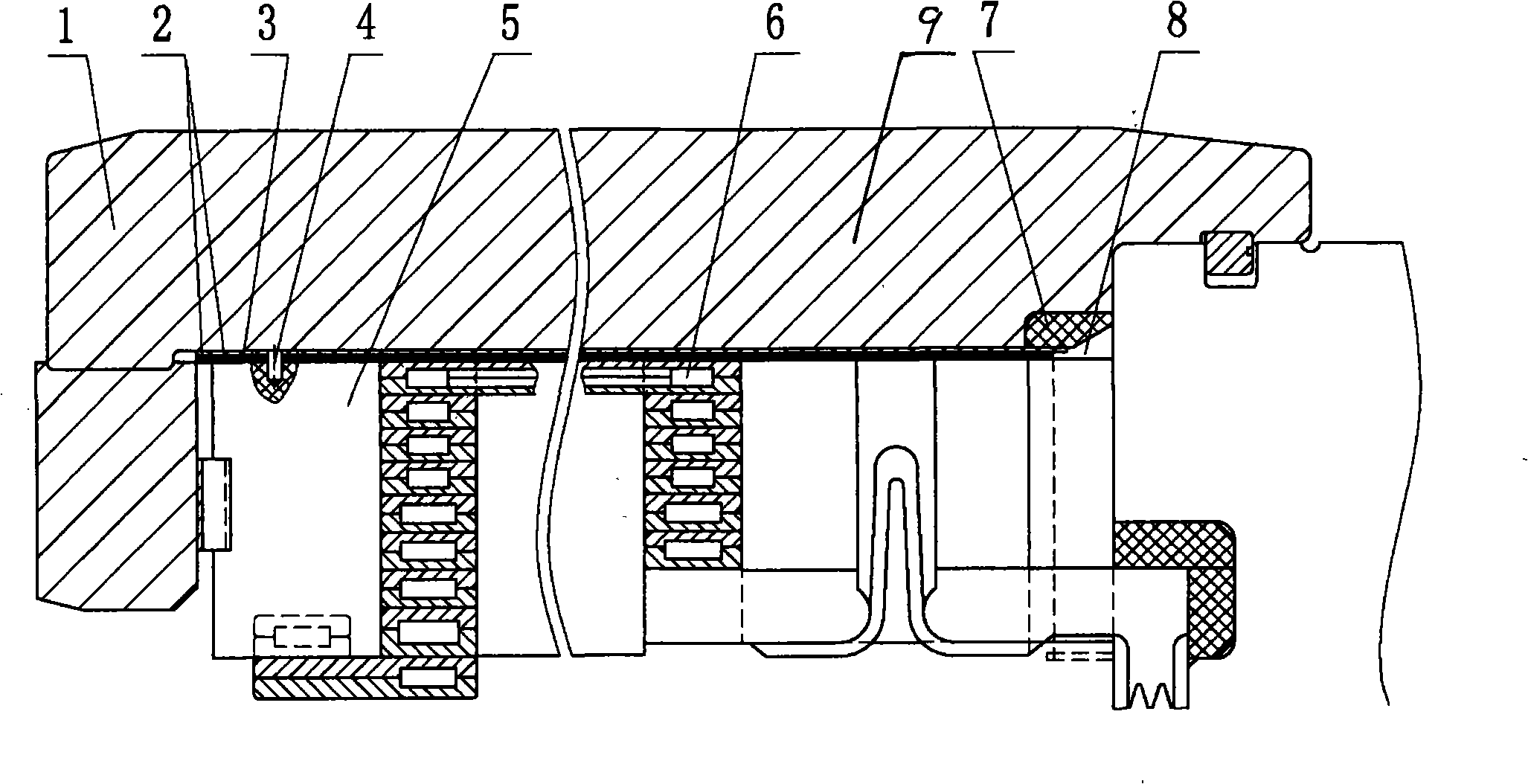

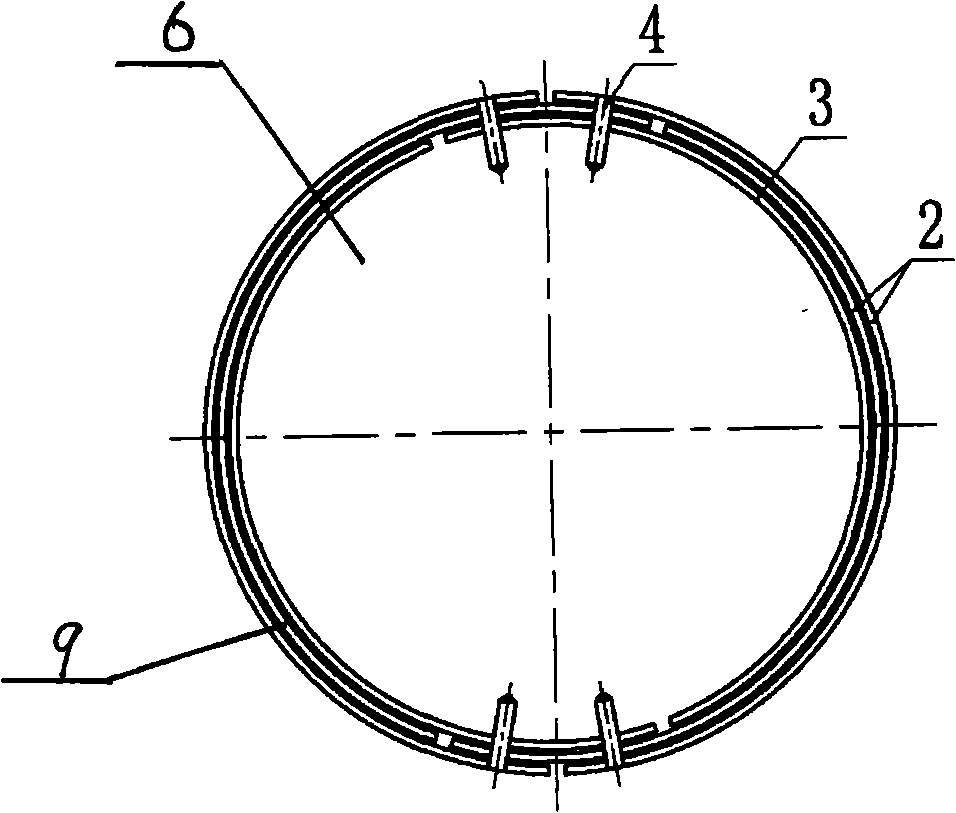

[0018] Such as figure 1 As shown, it is a schematic diagram of an installation method of a segmented insulation cylinder for a generator rotor retaining ring. The installation method for a segmented insulation cylinder for a generator rotor retaining ring uses two retaining ring segments 9 through bakelite pins 4 Installed on the outside of the rotor winding 6 to form an insulating tube, the grommet sub-block 9 consists of a grommet 1, a high-strength epoxy glass cloth plate 2, a DDS plate compounded with tetrafluoro cotton cloth, that is, a layer 3 close to the copper wire, Bakelite pin 4, end spacer, insulating ring 7 and pad strip 8 under the wedge are formed, and its installation method is:

[0019] The outer half of the rotor winding 6 is wrapped with DDS board compounded with tetrafluoro cotton cloth 3; the high-strength epoxy glass cloth board 2 is wrapped outside the DDS board compounded with tetrafluoro cotton cloth 3; the high-strength epoxy glass cloth board 2 and D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com