Electromechanical combination preparation process and apparatus for hydrogen by spray method

A spray method, electromechanical technology, applied in the field of hydrogen production process and equipment, can solve the problems of difficult decomposition of water molecules, slow decomposition speed, low efficiency, etc., to achieve the effects of accelerated reaction speed, improved efficiency and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

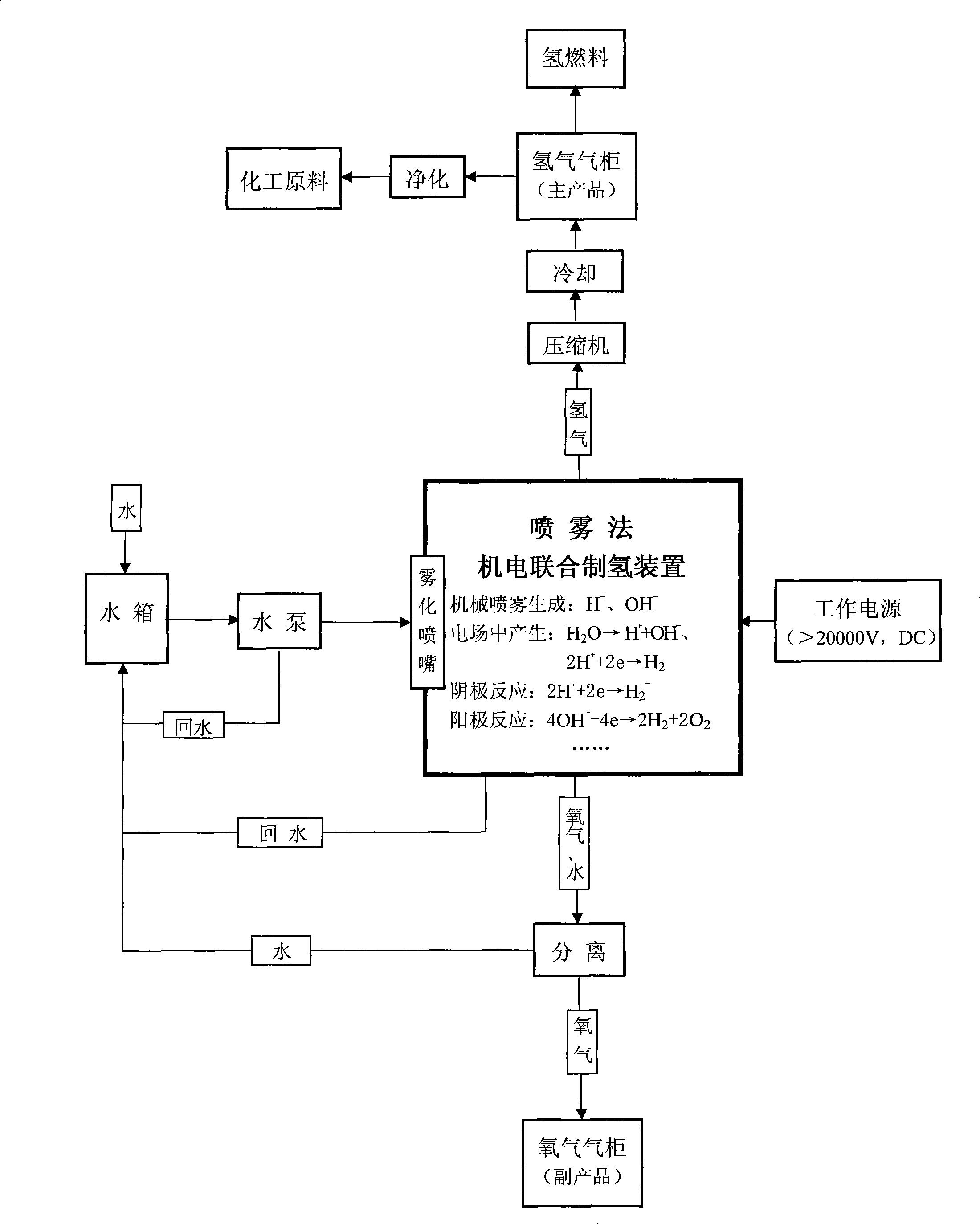

[0028] figure 1 In the process of combined electromechanical hydrogen production by spraying method shown, water is pressurized by a water pump and then sprayed into the combined electromechanical hydrogen production device through an atomizing nozzle. Under the combined action of mechanical force and electric field force, water molecules are ionized into hydrogen ions ( h + ) and hydroxide ions (OH - ), and then generate hydrogen and oxygen. The hydrogen is extracted from the device by the compressor, cooled by the cooling device, and then sent to the gas cabinet. The hydrogen in the gas cabinet can be directly burned or purified as chemical raw materials; oxygen and The unreacted water mist is output from the device, and the by-product oxygen is obtained through the separation device, and the separated water is sent back to the water tank for recycling; the remaining water in the device and the water pump are returned to the water tank for recycling; the power supply to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com