Micro-aeration vertical flow wetland sewage purification technology

A vertical flow wetland and micro-aeration technology, which is applied in the field of artificial wetland sewage purification system, can solve the problems of reduced oxidation and decomposition rate of organic matter, difficulty in removal, and low wetland purification efficiency, so as to increase processing capacity, prolong service life, and increase purification effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

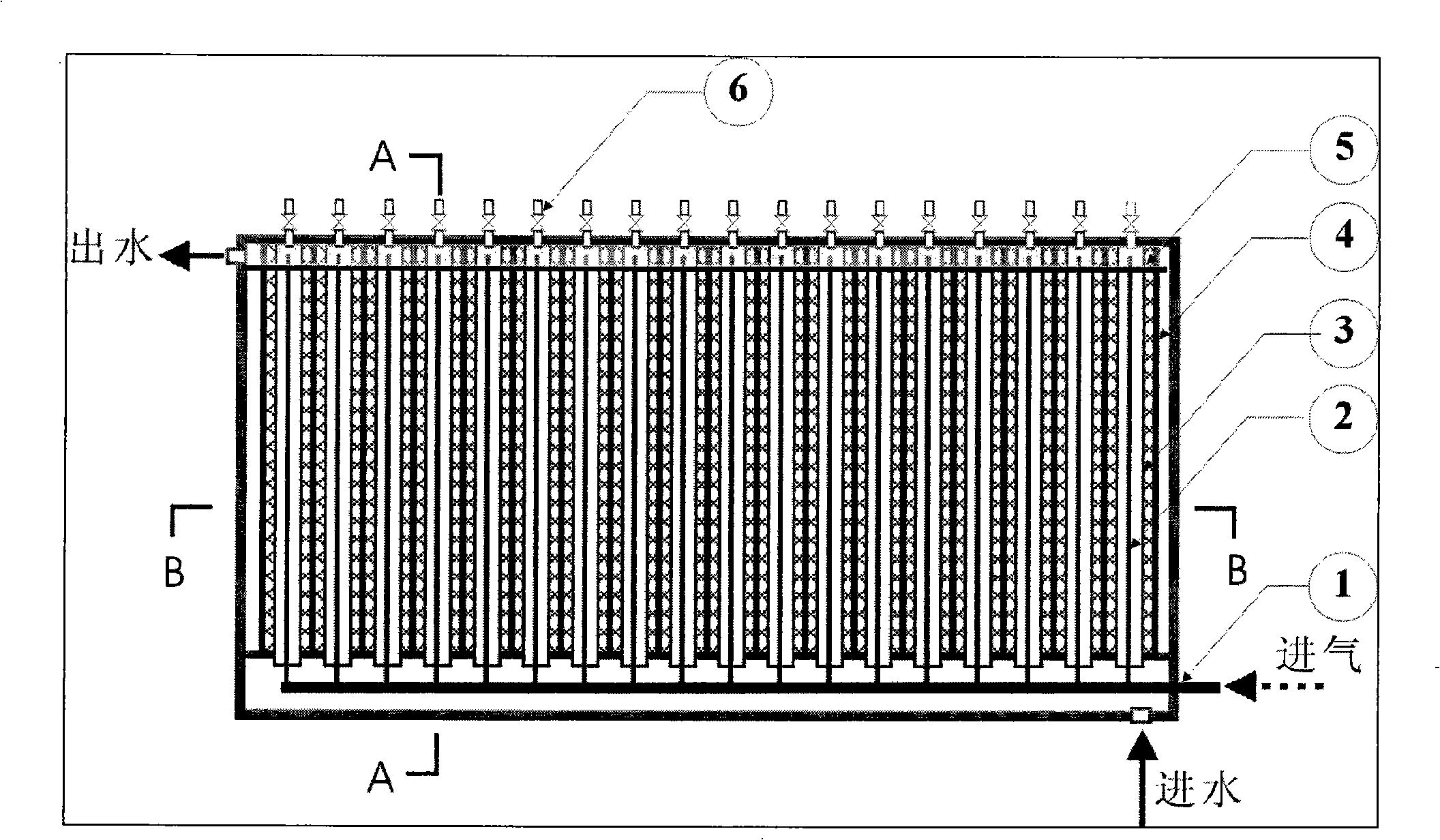

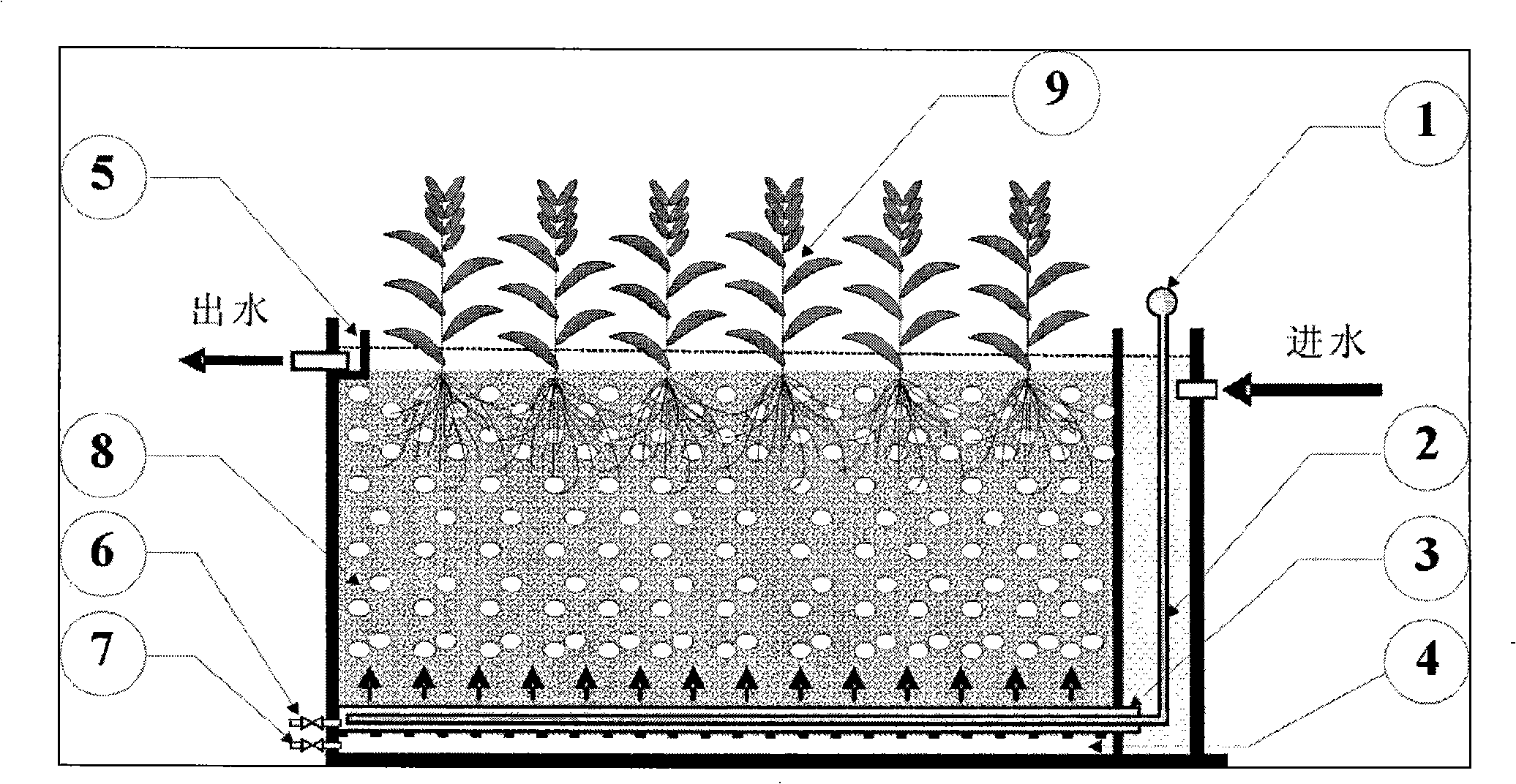

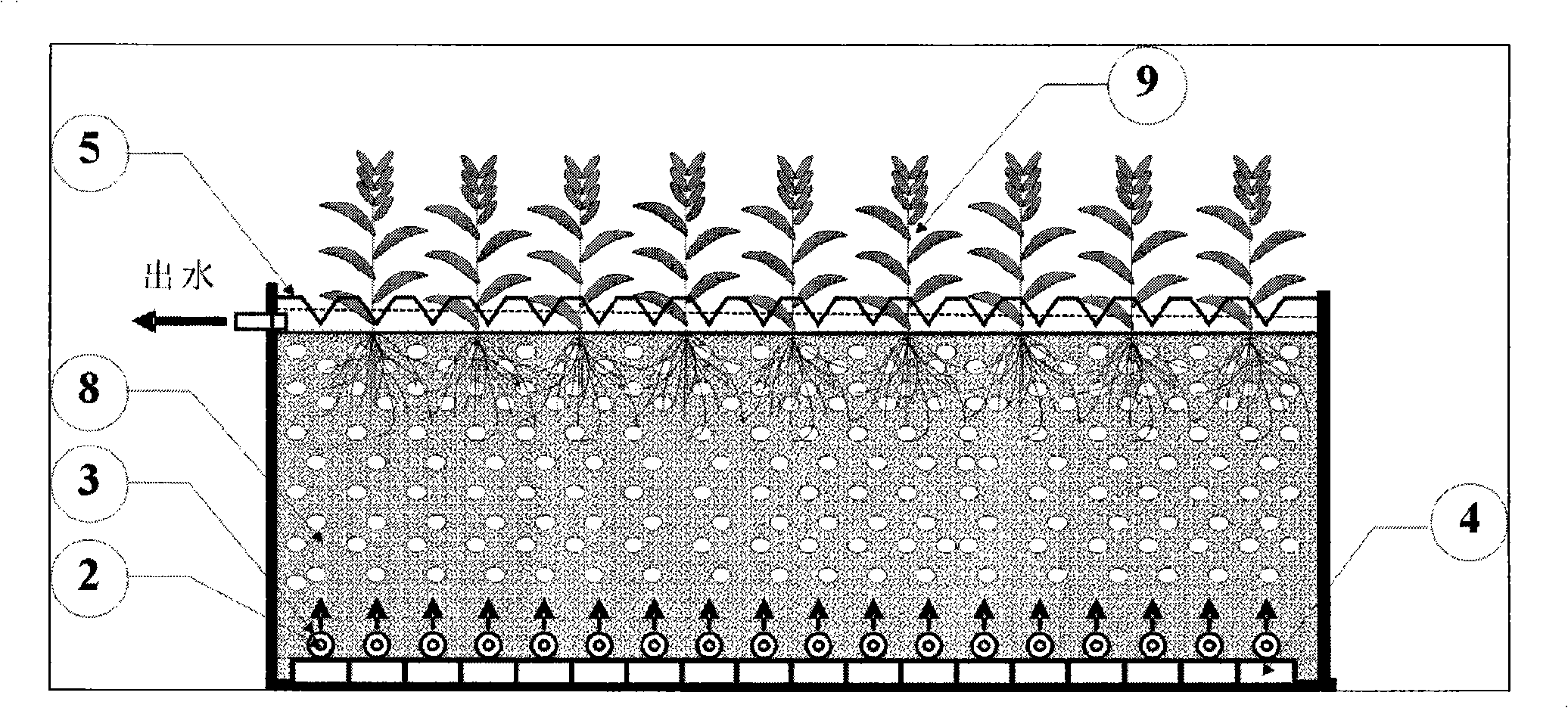

[0011] Sewage flows vertically into the wetland through micro-aeration. The water distribution pipes at the bottom of the wetland (Fig. 3) evenly flow into the wetland from bottom to top. At the same time, compressed air passes through the aeration pipes arranged in the water inlet pipes (Fig. 1, 2). Aerate and oxygenate the wetland system to improve the oxidative decomposition and nitrification effect of organic matter. Set up a sediment output corridor (Figure 4) under the water distribution pipe to regularly discharge the deposited organic debris and suspended matter through the pipe to the wetland. There is a flushing pipe (Figure 6) at the top of the water distribution pipe, and the valve is opened regularly for flushing according to the stasis in the pipe. In order to reduce the impact of bottom sediment on the wetland system, the effluent from the micro-aerated vertical flow wetland is collected through the weir (Fig. 5) and then discharged out of the system. This set o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com