Nano magnesium hydrate combustion inhibitor using agustite as crystal nucleon component and preparation method

A technology of nano-magnesium hydroxide and apatite, applied in the field of nano-magnesium hydroxide and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] At room temperature, add 1.67g of calcium chloride to 150ml of ammonia solution and mix well to form a uniform solution (pH 10), add 0.21g of sodium dodecylbenzenesulfonate and mix well to form solution A. Fully dissolve 6.09g of magnesium chloride hexahydrate in 120ml of deionized water to obtain uniform transparent solution B. Dissolve 0.08g of sodium phosphate in 10ml of deionized water and mix well to obtain a transparent solution C. Add solution C dropwise to solution A at room temperature and fully stirred at a rate of 15-25 drops / min, and then add solution B dropwise to the reaction system at a rate of 30-35 drops / min, and stir vigorously (300-350 RPM) for 2 hours, aged at room temperature for 12 hours, filtered, washed with deionized water to a pH of about 6.5, and dried at 120°C for 8 hours to obtain a nano-magnesium hydroxide flame retardant with apatite as the crystal nucleus.

Embodiment 2

[0025] At room temperature, add 10.62g of calcium nitrate to 150ml of ammonia solution to form a uniform solution with pH 11, add 0.33g of sodium lauryl sulfate and stir well to form solution A. Dissolve 18.43g of magnesium nitrate hexahydrate in 120ml of deionized water to prepare uniform transparent solution B. Dissolve 3.54g of dipotassium hydrogen phosphate in 13ml of deionized water to prepare a uniform and transparent solution C. Add solution C dropwise to solution A at room temperature with stirring at a rate of 15-25 drops / min, and then add solution B dropwise at a rate of 30-35 drops / min and stir vigorously (300-350 rpm)2 After 12 hours, age at room temperature for 12 hours, filter, wash with deionized water to a pH of about 6.5, and dry at 120°C for 8 hours to obtain a nano-magnesium hydroxide flame retardant with apatite as the crystal nucleus.

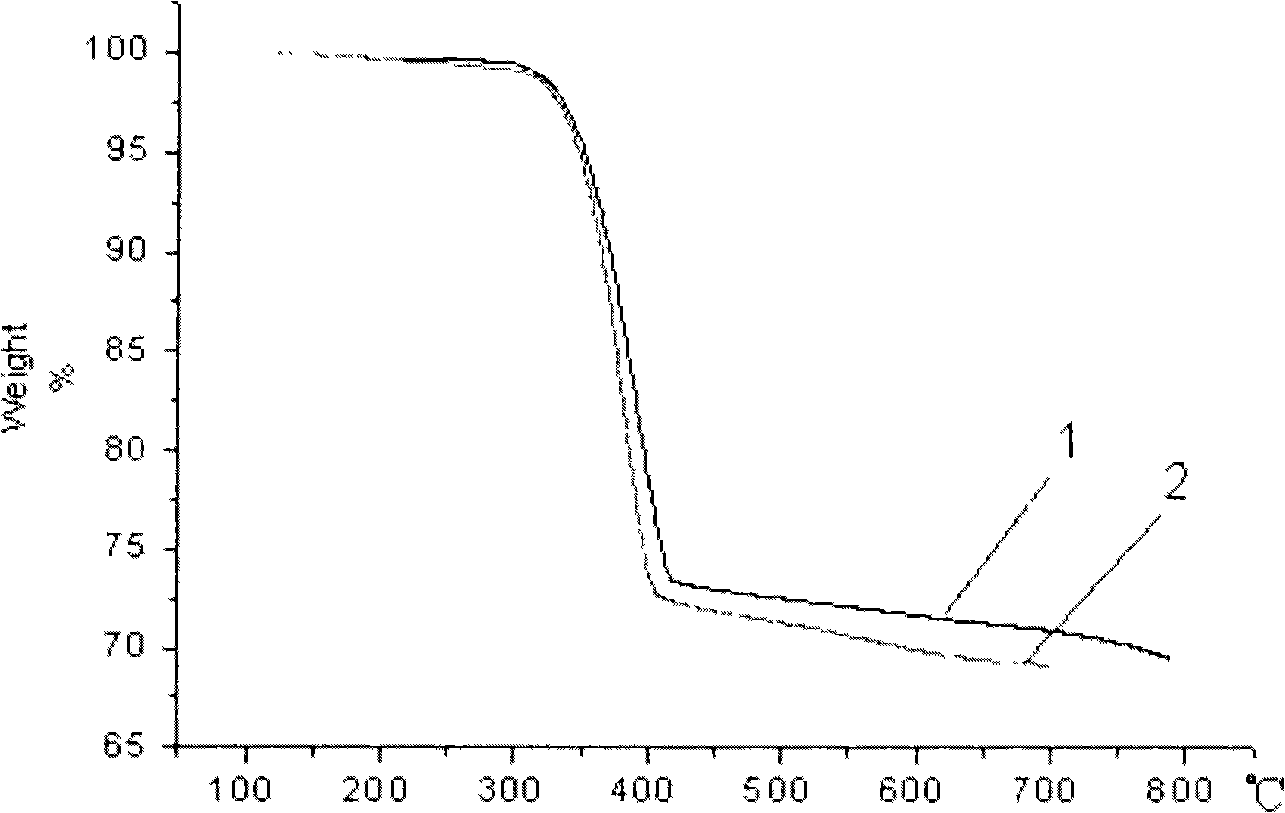

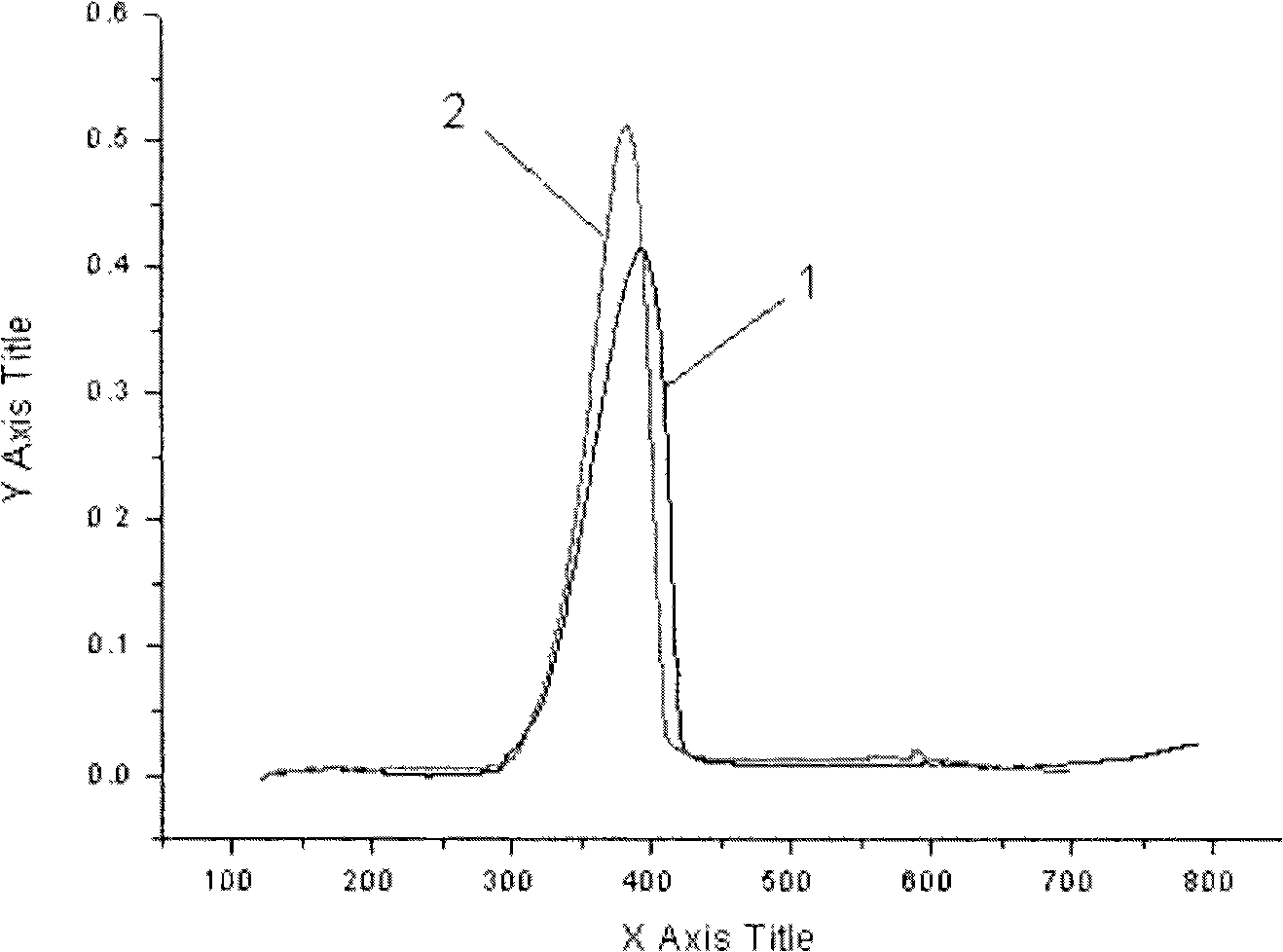

[0026] The thermogravimetric (TG) curve analysis test result of above-mentioned product and comparative example product ...

Embodiment 3

[0030] Add 3.3g of calcium chloride to 150ml of ammonia solution at room temperature to form a uniform solution (pH 13), add 0.26g of OP-10 anionic surfactant and stir well to form solution A. Dissolve 12.64g of magnesium chloride hexahydrate in 120ml of deionized water to prepare uniform transparent solution B. Dissolve 0.14g of sodium phosphate in 10ml of deionized water to prepare a homogeneous and transparent solution C. Add solution C and solution B dropwise to the reaction system according to the method of the above-mentioned Example 1 under room temperature and stirring, stir vigorously (300-350 rpm) and react for 2 hours, then age at room temperature for 12 hours, filter, and deionized water Wash until the pH is about 6.5, and dry in an oven at 120°C for 8 hours to obtain a nano-magnesium hydroxide flame retardant with apatite as the crystal nucleus.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com