A manganese bioxide electrochemical super capacitor

A technology of supercapacitor and manganese dioxide, which is applied in the field of capacitors, can solve the problems of difficult breakthrough of EDLC energy density, achieve high energy density and increase the average output voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

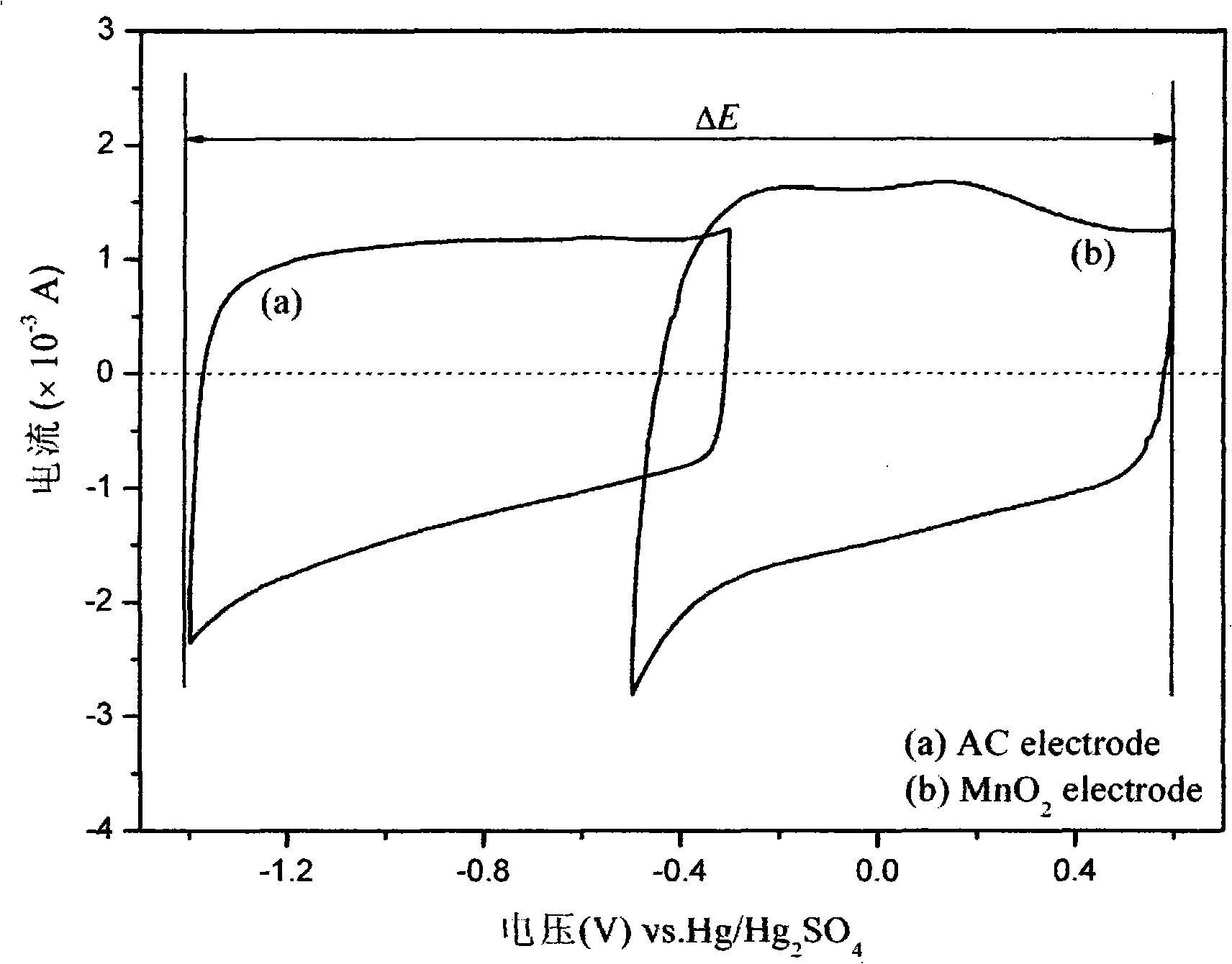

Embodiment 1

[0021] The manganese dioxide positive electrode material was prepared by microemulsion method, and a certain amount of surfactant sodium bis(2-ethylhexyl)sulfosuccinate (sodium bis(2-ethylhexyl)sulfosuccinate, AOT) was put into isooctane and stirred evenly to form a concentration of 0.1mol / L solution, while stirring, add a certain amount of potassium permanganate aqueous solution with a concentration of 0.1mol / L and make the molar ratio of water and surfactant AOT to 60. After all the addition is complete, continue stirring for 4h. Then carry out suction filtration, filter with water and absolute ethanol for 5 times respectively to obtain a brown filter cake, and dry to obtain black manganese dioxide powder. Using water as a dispersant, mix the prepared manganese dioxide, conductive agent acetylene black, and binder PTFE (polytetrafluoroethylene) in a mass ratio of 55:35:10, press it on a stainless steel mesh, and cut it into a certain size. Size, dry in vacuum. Commercial ac...

Embodiment 2

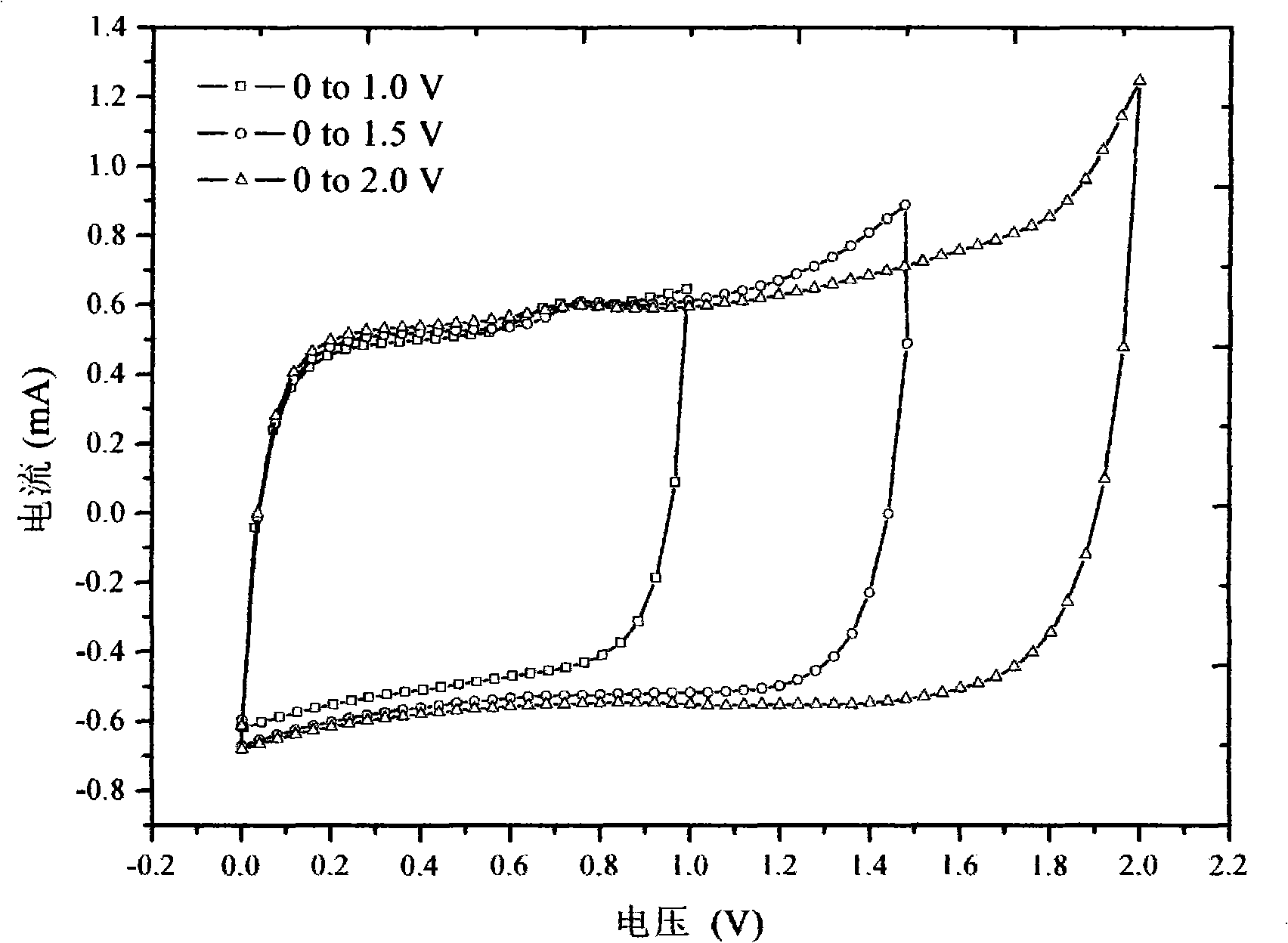

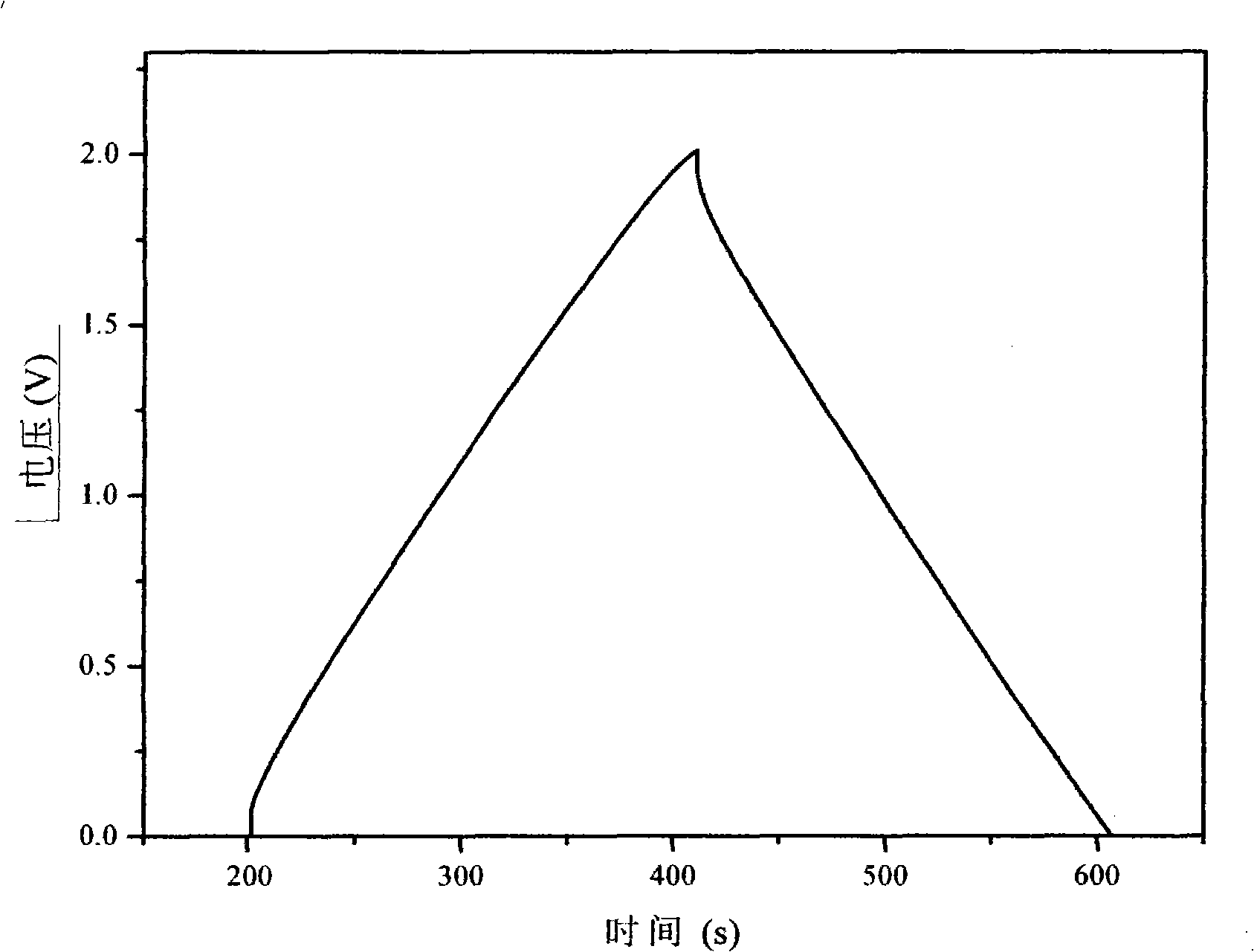

[0023] With manganese dioxide as the positive electrode, activated carbon as the negative electrode, and a commercial supercapacitor separator as the diaphragm, 0.1mol / L Ca(NO 3 ) 2 The aqueous solution is used as the electrolyte to assemble the button capacitor. The preparation of the positive electrode material and the positive and negative electrode membranes is as in Example 1, and the mass ratio of the positive and negative electrode active materials manganese dioxide and activated carbon is 1:3. The cyclic voltammogram of the electrochemical capacitor is shown in Example 2, and the scan rate is 2mV / s. When the current is 0.5A / g, the constant current charge and discharge curve of this capacitor is shown in Example 3. The working voltage of this capacitor can reach 2V, which is greatly improved compared with EDLC (1V), and the specific energy has reached 26Wh / Kg (based on Calculate the total mass of positive and negative active materials).

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com