Lithium ion power cell with high power

A power battery and lithium-ion technology, which is applied in the field of high-power lithium-ion power batteries, can solve problems such as limited effectiveness, impact on battery life, and potential explosion hazards that limit the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

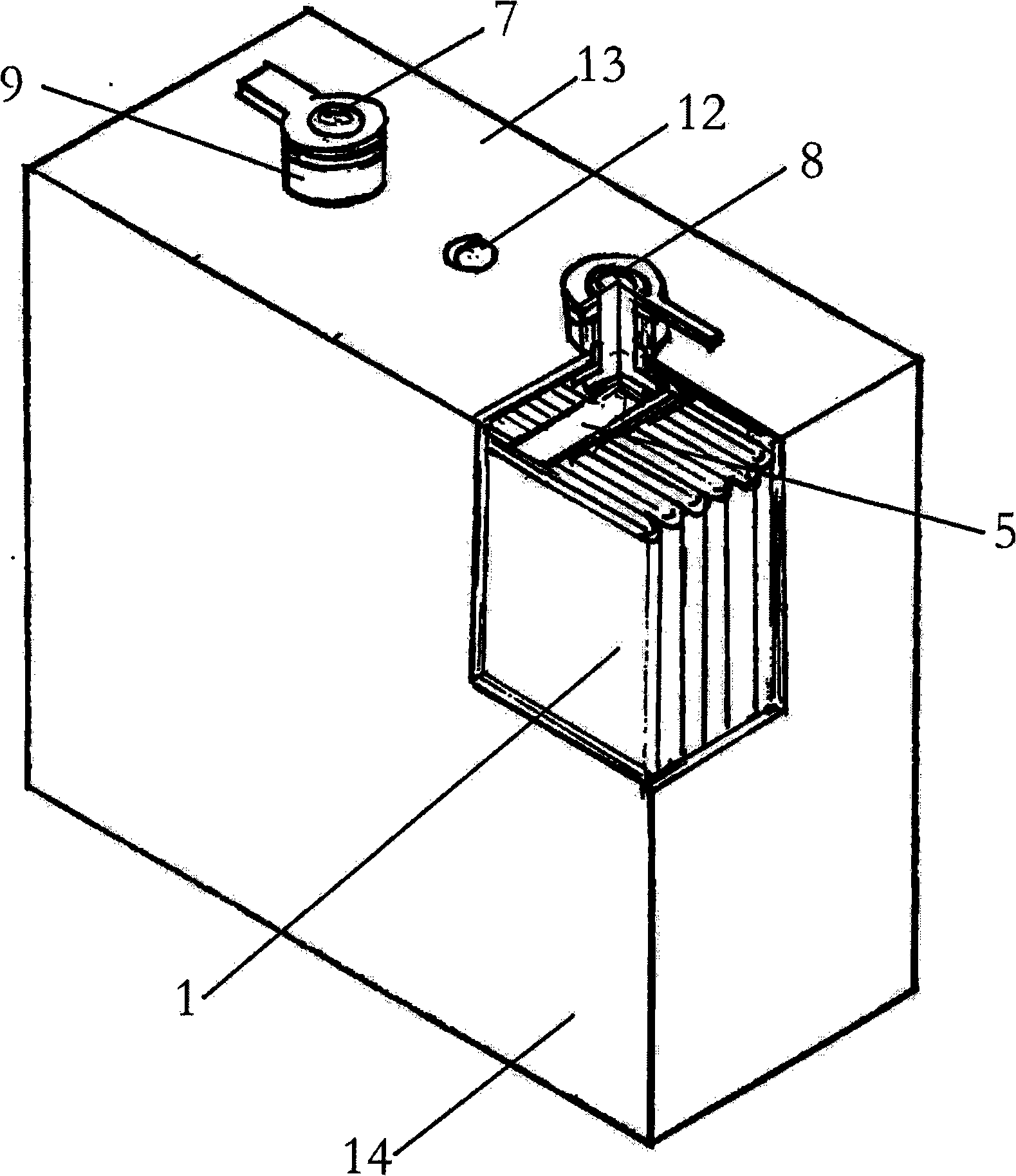

[0026] This example is a 10Ah pure lithium manganate power battery with external dimensions (excluding poles) of 70mm × 34mm × 70mm (length × width × height) that can be charged and discharged at 4C, and the minimum diameter of the pole column section is 3-6mm.

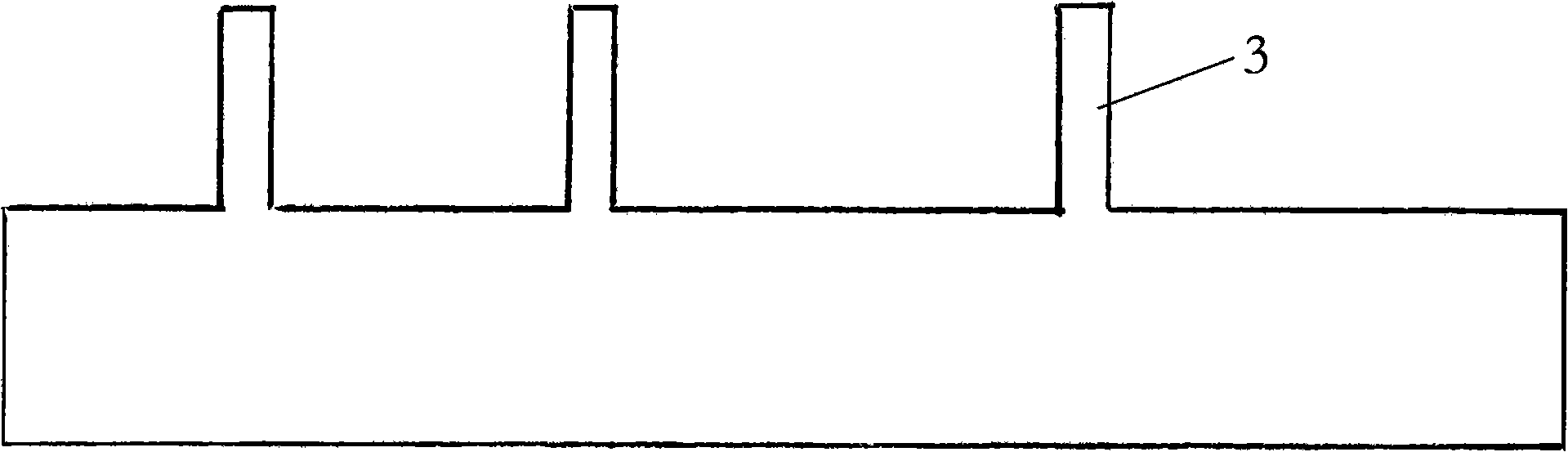

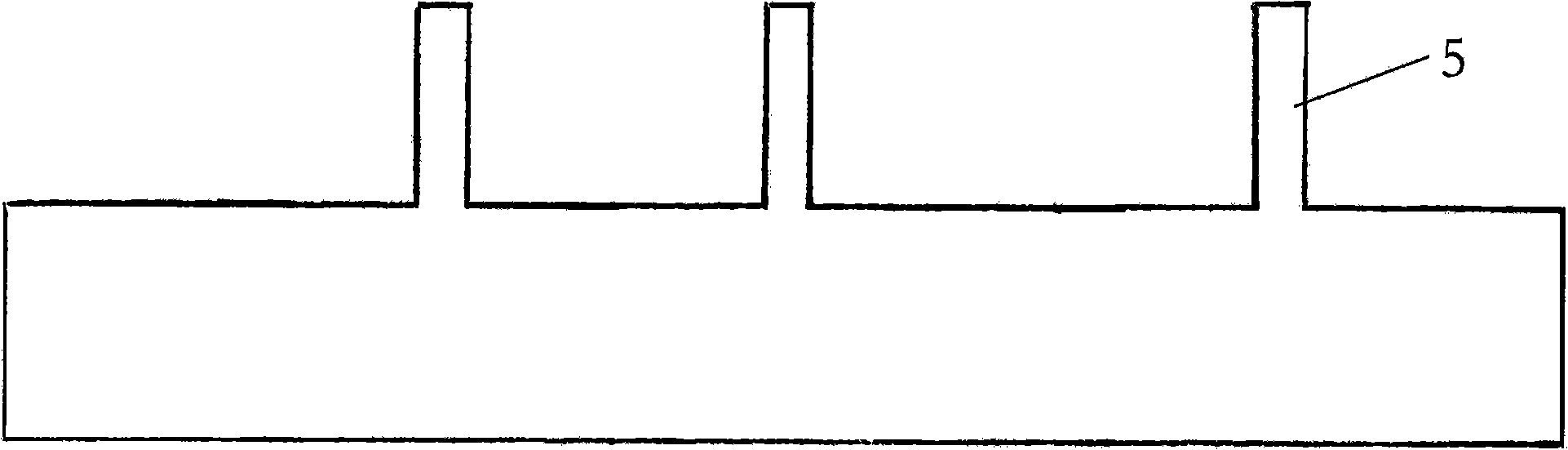

[0027] First, use lithium manganate material, carbon black, binder, and solvent to make positive electrode slurry by ultrasonic mixing, in which carbon black accounts for 1-6% of the total solid mass, and the binder accounts for 2-6% of the total solid mass. 6%, and the rest are lithium manganate materials; use natural graphite, carbon black, binder, and solvent to make negative electrode slurry by ultrasonic mixing, in which carbon black accounts for 0.5-6% of the total solid mass, and the binder accounts for 0.5-6% of the total solid mass. 2-6% of the total solid mass, the rest is natural graphite. The gap coating is carried out according to the mass ratio of positive active material to negative active material equa...

example 2

[0034] The specific operation is the same as that of Example 1. For the sake of brevity, the same parts will not be repeated here, except that the number of pole lugs punched out from each positive and negative electrode sheet is 4, and the ultrasonic welding pattern area of the pole lug and the pole post is 3mm 2 . The test shows that the rate discharge performance of 4C, the cycle performance of 1C and the internal resistance of Example 2 are not significantly different from those of Example 1.

example 3

[0036]This example is an 8Ah pure lithium manganate power battery with external dimensions (excluding poles) of 70mm × 34mm × 70mm (length × width × height) that can be charged and discharged at 15C. The diameter of the minimum section of the stainless steel positive pole stud bolt It is 6-10mm, and the diameter of the minimum section of the brass negative pole stud bolt is 4-8mm.

[0037] First, use lithium manganate material, carbon black, binder, and solvent to make positive electrode slurry by ultrasonic mixing, in which carbon black accounts for 1-6% of the total solid mass, and the binder accounts for 2-6% of the total solid mass. 6%, and the rest are lithium manganate materials; use natural graphite, carbon black, binder, and solvent to make negative electrode slurry by ultrasonic mixing, in which carbon black accounts for 0.5-6% of the total solid mass, and the binder accounts for 0.5-6% of the total solid mass. 2-6% of the total solid mass, the rest is natural graphit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contact resistance | aaaaa | aaaaa |

| Contact resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com