Carbon nitrogen nano fiber loaded platinum ruthenium nano particle electrode catalyst and preparation method

An electrode catalyst, nanoparticle technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as increasing process difficulty, preparation cost, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

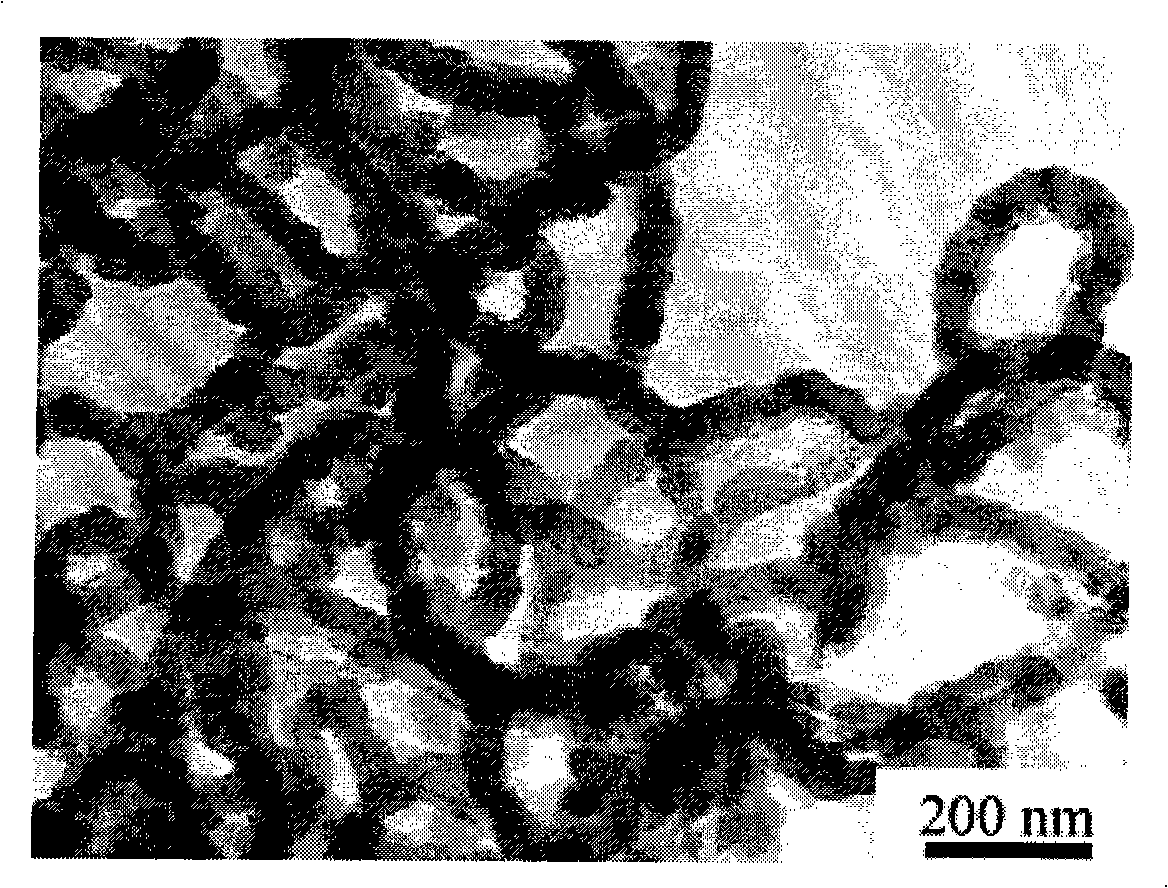

[0017] Embodiment 1: 0.1g carbon-nitrogen nanofiber is uniformly dispersed in the ethylene glycol 100% (general 10-100%) solution of 50mL chloroplatinic acid and ruthenium chloride, Pt and Ru content are respectively 0.015g and 0.008g ( The molar ratio is 1:1), stirring for 1-4 hours, jumping the pH to 12-14, then raising the temperature to 100-180°C, reacting for 0.5-5h, filtering, washing, and vacuum-drying at 60°C to obtain platinum ruthenium supported by carbon-nitrogen nanofibers Nanoparticles, denoted as Pt 1.0 Ru 1.0 / CN x . TEM observation ( Figure 4 ), the particle size of the platinum ruthenium nanoparticles is distributed in the range of 1 to 15 nm. Inductively coupled plasma mass spectrometry analysis showed that the loaded nanoparticles were platinum and ruthenium, and the molar ratio of the two was approximately 1:1. Approximate results were obtained when using Pt and Ru contents of 0.0075 g and 0.008 g, respectively (molar ratio 0.5:1).

Embodiment 2

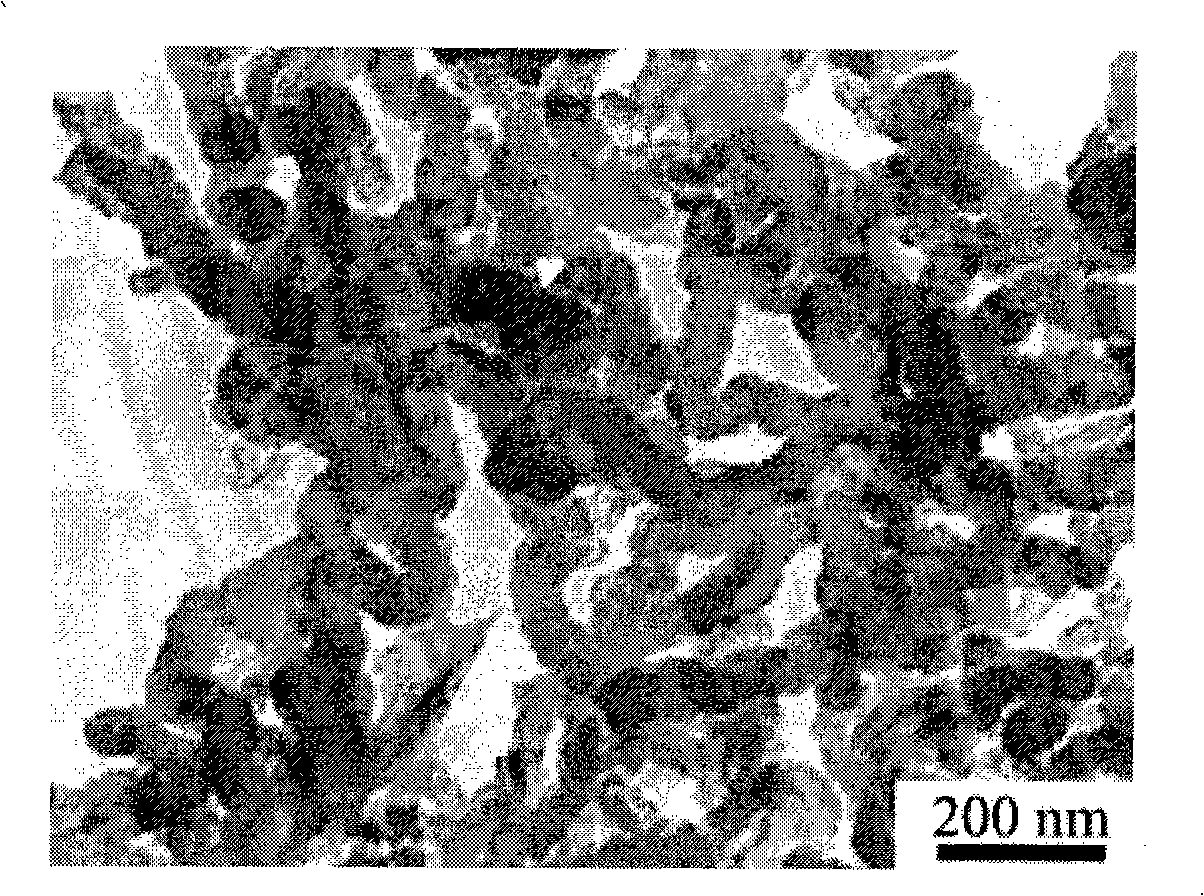

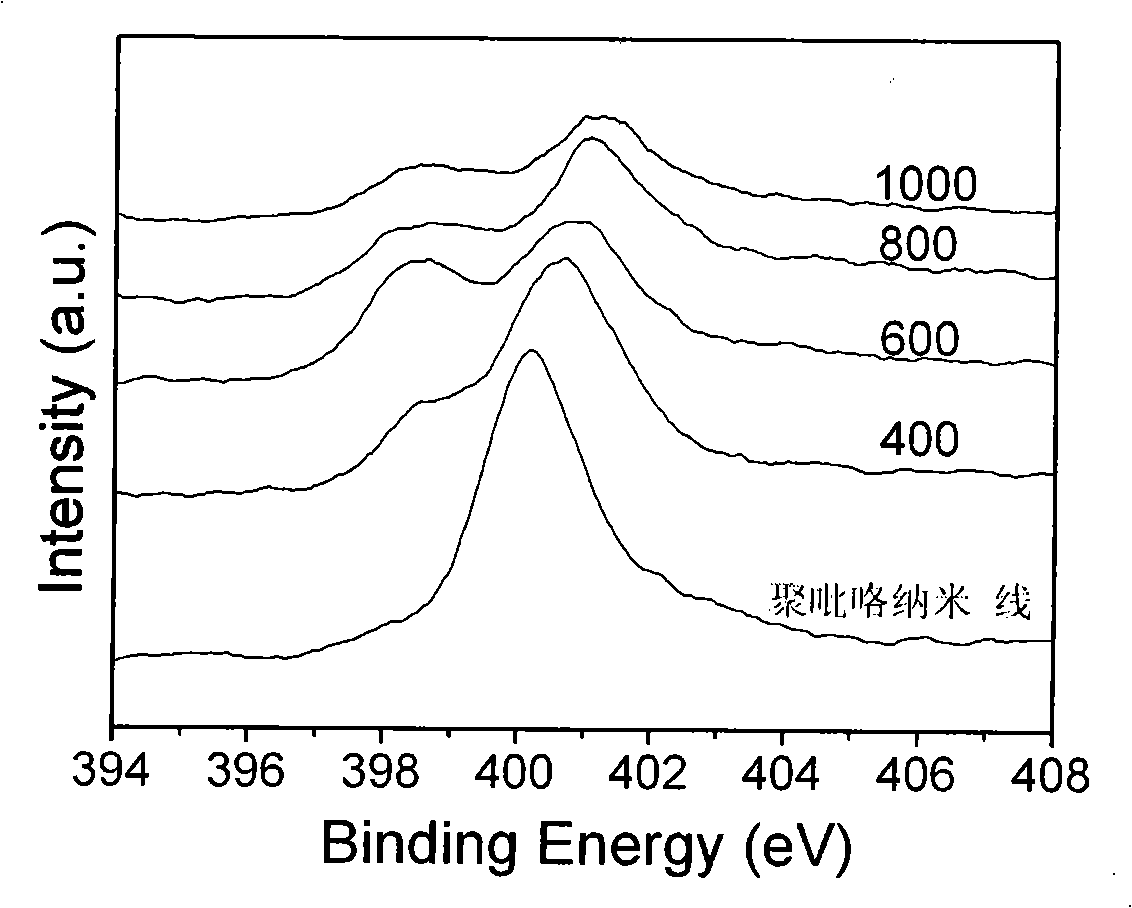

[0019] 1) Evenly disperse 0.1g of carbon-nitrogen nanofibers in 50mL of ethylene glycol solution of chloroplatinic acid, with a Pt content of 0.015g, stir for 1-4h, ultrasonicate for 5-30min, and adjust the pH to 12-14. Then place it in a microwave oven, irradiate at 500W for 200s, filter, wash, and dry to obtain platinum-ruthenium nanoparticles supported by carbon-nitrogen nanofibers, denoted as Pt / CN x . TEM observation ( Figure 5 ), the particle size distribution of platinum nanoparticles is in the range of 1-15nm. High-resolution transmission electron microscope photos ( Image 6 ) and X-ray diffraction spectrum ( Figure 7 ) diffraction peaks indicate that the loaded nanoparticles are platinum nanoparticles. When a single platinum acetate or potassium chlororuthenate is used, or ruthenium particles are the same as above.

[0020] 2) Using the platinum nanoparticles supported by the carbon-nitrogen nanofibers as a catalyst for the catalytic reaction of anodic oxidati...

Embodiment 3

[0021] Embodiment 3: 0.1g carbon-nitrogen nanofiber is uniformly dispersed in the aqueous solution of 50mL chloroplatinic acid and ruthenium chloride, Pt and Ru content are respectively 0.015g and 0.008g (molar ratio is 1: 1), stir 4h, then Slowly add (such as dropwise) the mixed solution of sodium borohydride and sodium hydroxide with a concentration of 0.05mol / L (generally 0.01~0.15mol / L) and 0.01mol / L (generally 0.005~0.03mol / L) respectively until the reaction The pH value of the system is 11 (generally 10-12), and a product similar to Example 1 is obtained after 1 hour of reaction (generally 0.5-3 hours). Approximate results were obtained when using Pt and Ru contents of 0.0075 g and 0.008 g, respectively (molar ratio 0.5:1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com