Semi-forced ventilation static sludge aerobic compost method

An aerobic composting and forced ventilation technology, applied in sewage/sludge fertilizers, organic fertilizers, fertilization devices, etc., can solve the problems of low utilization rate of the pipeline system, difficult to achieve precise control, poor quality of composting products, etc. Construction investment, small environmental impact, and the effect of reducing nitrogen loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Crushing the waste wood to less than 100 mm;

[0026] (2) mix with the sludge of moisture content 80% according to the ratio of sludge: sawdust=1: 1 (weight ratio), and stir;

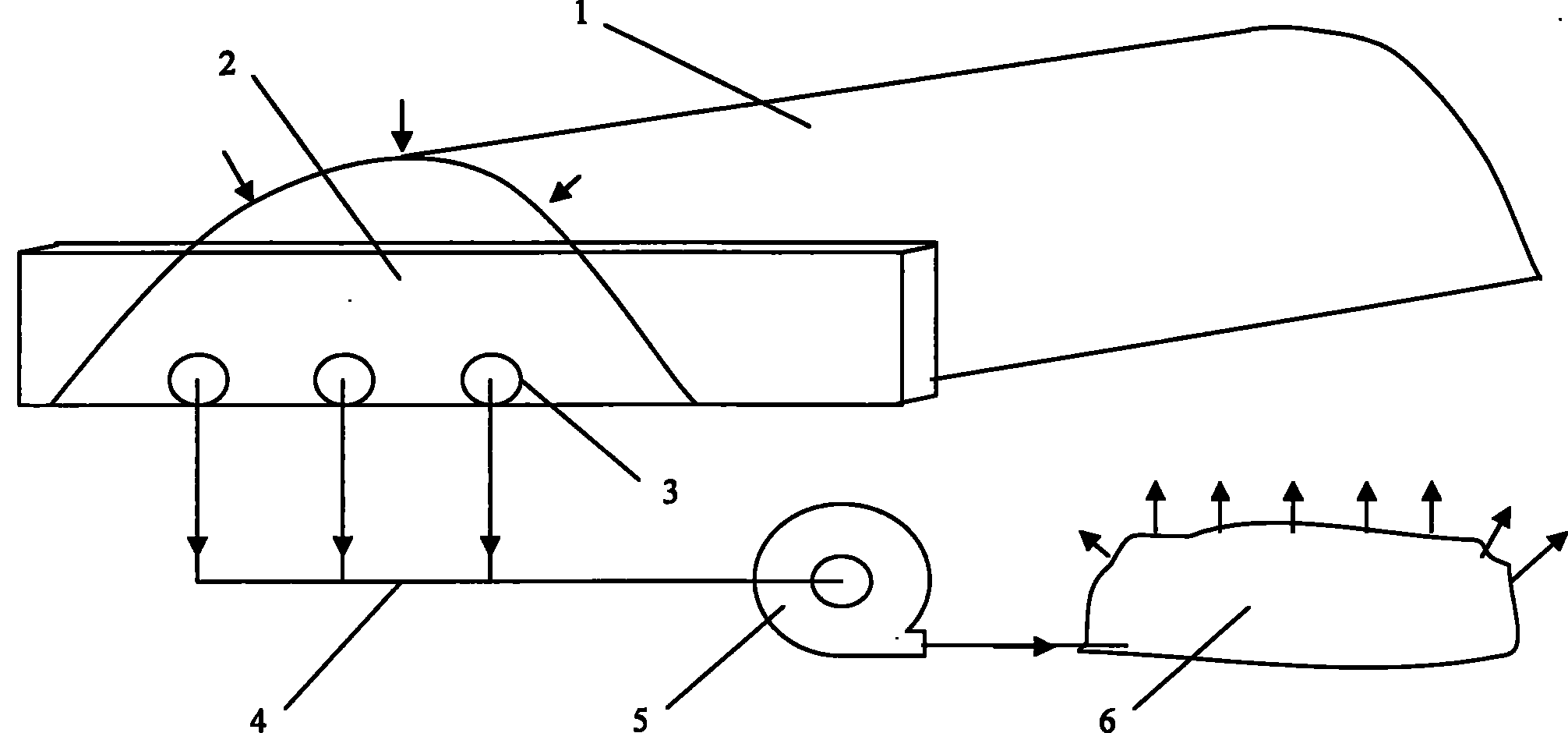

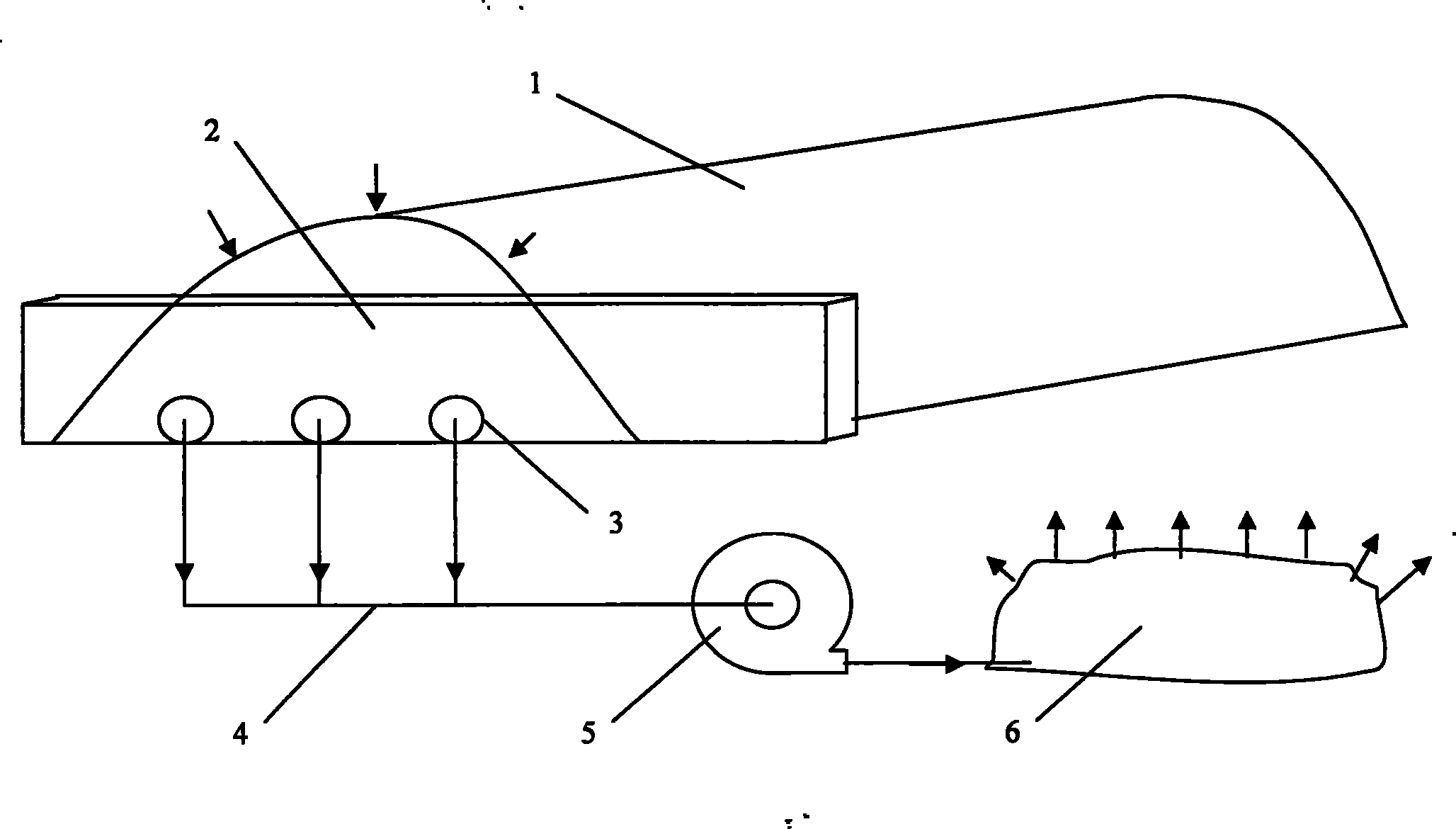

[0027] (3) Use a forklift to stack the mixture on the platform into a pile of trapezoidal sections with a height of 2.5 meters and a width of 6 meters. 10 pieces form a group, and a gap of 1.0 meters is left between the piles. The device processes two ventilation holes with a diameter of 600 mm and a spacing of 2.5 meters. A 1.2-meter-high retaining wall is set at one end of the stack, and a ventilation pipe interface is set on the wall corresponding to the ventilation hole. The ventilation pipe is connected to the fan. The other end of the fan leads to the exhaust gas treatment pool;

[0028] (4) Forced ventilation: After the stockpile is finished, cover the surface with a film, and monitor the temperature of the stockpile with a thermometer. When the temperature of the stockpile reaches 68...

Embodiment 2

[0031] (1) Crush the wood to less than 100 mm, crush the corn stalks to less than 80 mm, corn stalks: waste wood = 0.1:1;

[0032] (2) mix with the sludge with a moisture content of 80% according to the ratio of sludge: conditioning material=1:1 (weight ratio), and stir evenly;

[0033] (3) Use a forklift to stack the mixture on the platform into a pile of trapezoidal sections with a height of 2.0 meters and a width of 5.5 meters. 10 pieces form a group, and a gap of 0.5 meters is left between the piles. The device processes two ventilation holes with a diameter of 600 mm and a spacing of 2.5 meters. A 1.2-meter-high retaining wall is set at one end of the bar stack, and a ventilation pipe interface is set on the wall corresponding to the ventilation hole, and the ventilation pipe is connected to the fan. , the other end of the fan is connected to the waste gas treatment pool;

[0034] (4) Forced ventilation: After the stockpile is finished, cover the surface with a film, and...

Embodiment 3

[0037] (1) Shred wood to less than 100 mm, and shred agricultural waste such as straw and mushroom compost to less than 50 mm, agricultural waste: waste wood = 1:1;

[0038] (2) mix with the sludge with a moisture content of 75% according to the ratio of sludge: conditioning material = 1: 0.8 (weight ratio), and stir evenly;

[0039] (3) Use a forklift to stack the mixture on the platform into a pile of trapezoidal sections with a height of 1.8 meters and a width of 5 meters. 10 pieces form a group, and a gap of 0.5 meters is left between the piles. The device processes 3 ventilation holes with a diameter of 500 mm and a spacing of 1.3 meters. A 1.2-meter-high retaining wall is set at one end of the pile, and a ventilation pipe interface is set on the wall corresponding to the ventilation hole. The ventilation pipe is connected to the fan. The other end of the fan leads to the exhaust gas treatment pool;

[0040](4) Forced ventilation: After the stockpile is finished, cover t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com