Method for preparing ultramicro flour weevil albumen powder and shell matter by separating flour weevil dried products

A technology of Tenebrio molitor and protein powder, which is applied in the field of separation and preparation of ultrafine Tenebrio molitor protein powder and shell substances, can solve the problems that restrict the development of Tenebrio molitor industry, the utilization of Tenebrio molitor resources, low product quality, and solvent residues, and achieve the goal of promoting rural areas. Industrial adjustment, high product quality, and no solvent residue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

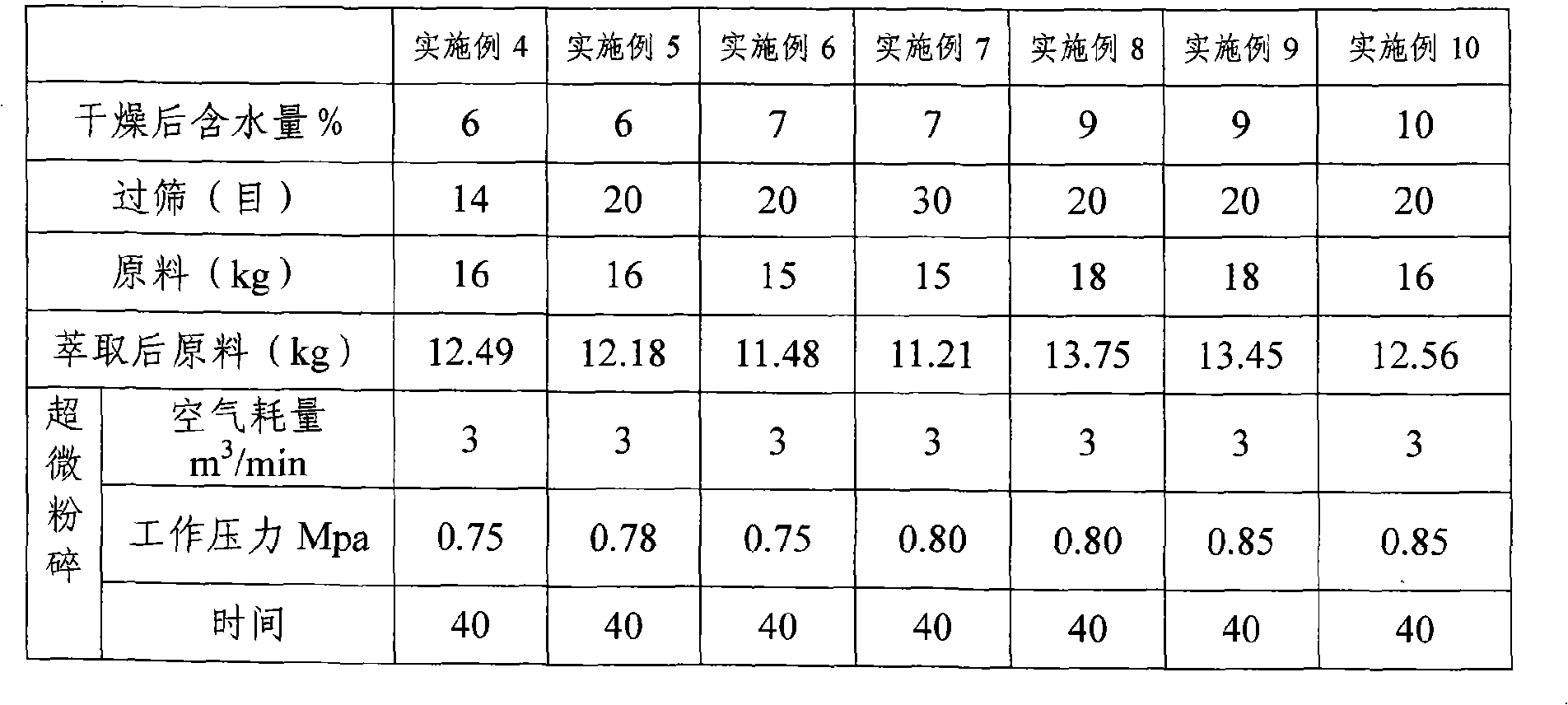

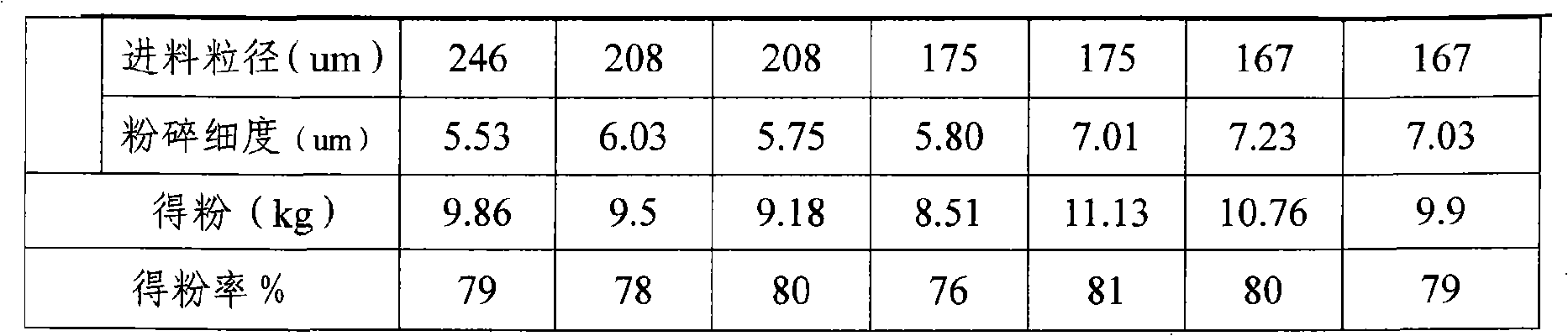

Embodiment 1

[0013] (steps 1, 2, 3 can refer to the Chinese invention patent application whose publication number is CN101117613 applied by the applicant)

[0014] 1. Microwave drying and sterilization of live Tenebrio molitor

[0015] Microwave working chamber: the temperature is 30-80°C, the drying time is 15 minutes, and the moisture content of dried Tenebrio molitor is 8.14%.

[0016] Explanation: If the moisture content is too high, it is easy to form a continuous phase water film on the surface of the particles, which affects the degreasing rate, and at the same time causes excessive moisture in the degreasing insect body, which will cause sticking phenomenon when processing ultra-fine powder. Therefore, the moisture content should be controlled at 6%-10%.

[0017] 2. Crush the dried Tenebrio molitor and sieve it with 20 mesh.

[0018] 3. Take 16kg of Tenebrio molitor powder through a 20-mesh sieve and carry out supercritical CO2 fluid extraction degreasing to obtain 12kg of defatt...

Embodiment 2

[0050] (steps 1, 2, 3 can refer to the Chinese invention patent application whose publication number is CN101117613 applied by the applicant)

[0051] 1. Microwave drying and sterilization of live Tenebrio molitor

[0052] Microwave working chamber: the temperature is 70-85°C, the drying time is 21 minutes, and the moisture content of dried Tenebrio molitor is 6% after drying.

[0053] 2. Crush the dried Tenebrio molitor and sieve it through a 14-mesh sieve.

[0054] 3. Weigh 20kg of its dry product and carry out supercritical CO 2 Fluid extraction degreasing. 15.36 kg of defatted worm bodies were obtained.

[0055] 4. Pre-crushing the defatted worms to 100 mesh.

[0056] 5. The pre-crushed Tenebrio molitor powder is crushed by microgravity supersonic collision. The time was 40 minutes, and 12.13 kg of superfine powder was obtained.

Embodiment 3

[0058] (steps 1, 2, 3 can refer to the Chinese invention patent application whose publication number is CN101117613 applied by the applicant)

[0059] 1. Microwave drying and sterilization of live Tenebrio molitor.

[0060] Microwave working chamber: the temperature is 73-84°C, the drying time is 10 minutes, and the moisture content of dried Tenebrio molitor is 10% after drying.

[0061] 2. Crush the dried Tenebrio molitor and sieve it through a 30-mesh sieve.

[0062] 3. Weigh 15kg of sieved Tenebrio molitor body for supercritical CO 2 Fluid extraction and degreasing yielded 11.4 kg of defatted Tenebrio molitor bodies.

[0063] 4. Pre-crushing the defatted Tenebrio molitor to 80 mesh.

[0064] 5. The defatted Tenebrio molitor powder was collided and pulverized by microgravity supersonic airflow for 40 minutes to obtain 8.89 kg of ultrafine micronized Tenebrio active protein powder.

[0065] The airflow pulverizer used in the present invention can be selected in the existi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com