Method for directly producing metallic iron powder with high-alumina iron ore

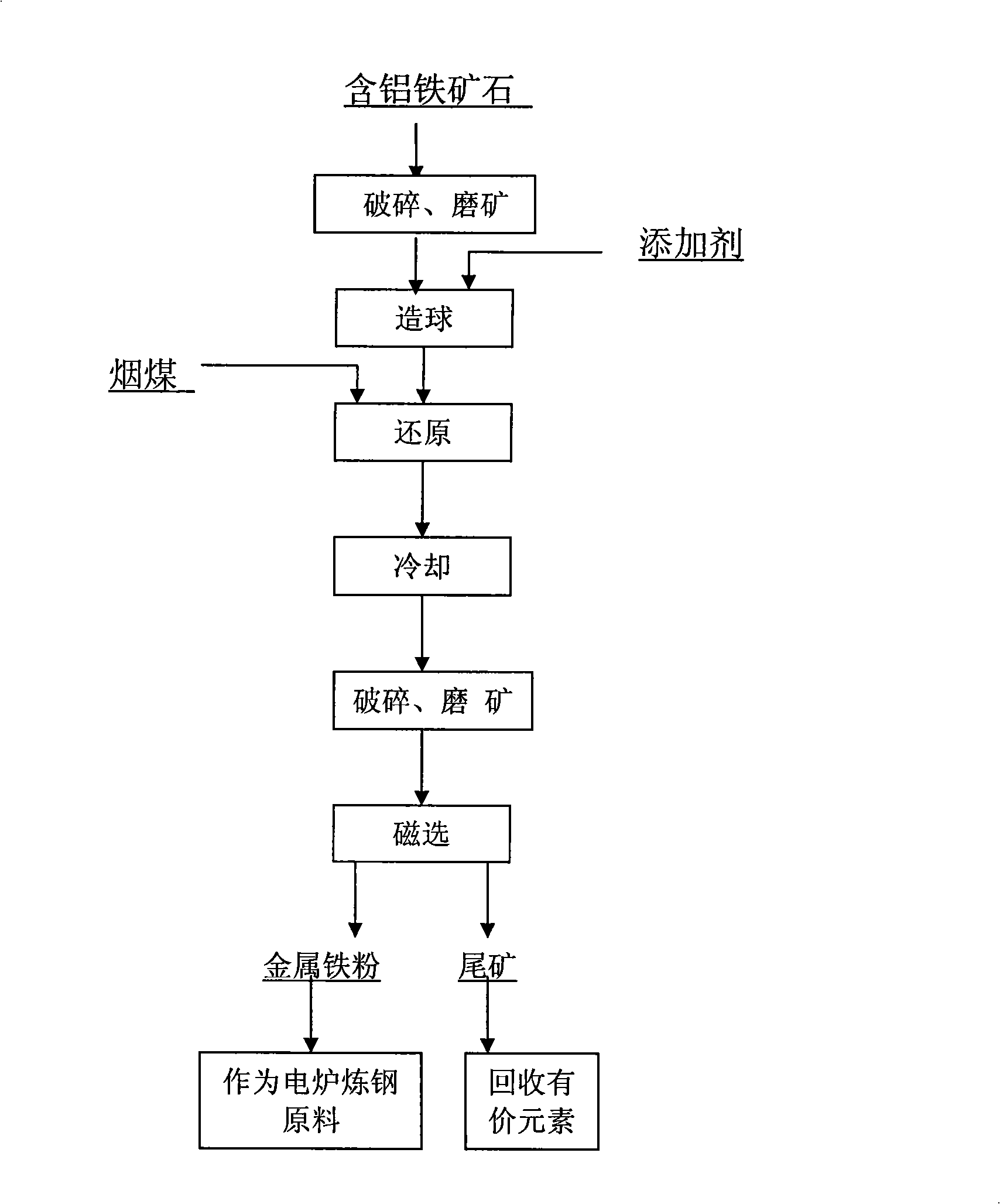

A technology for iron ore and metallic iron, applied in the field of high-alumina iron ore iron-aluminum separation, can solve the problems of large environmental pollution, long process and high energy consumption, and achieve the effects of less environmental pollution, improved quality and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Example 1: TFe content 57.35%, Al 2 o 3 Content 5.43%, SiO 2 Iron ore with a content of 3.52%, crushed and ground to 85% of -200 mesh, mixed with sodium sulfate and sodium borate in proportions of 10% and 2% by mass to make pellets, using bituminous coal as a reducing agent, dry pellets Roast at 1000°C for 60 minutes, crush the cooled reduced pellets, place them in a ball mill and grind them to -200 mesh with a pulp concentration of 50% to account for 90%, and magnetically separate the pulp at a magnetic field strength of 0.1T. Ore TFe grade 93.3%, Al 2 o 3 content of 0.78%, SiO 2 The content is 0.23%, and the recovery rate of iron is 93.6%.

Embodiment 2

[0011] Example 2: TFe content 47.69%, Al 2 o 3 Content 8.96%, SiO 2 The iron ore with a content of 4.30% is crushed and ground to -200 mesh, accounting for 80%. According to the mass percentage of 15% and 2.5%, sodium sulfate and sodium borate are respectively mixed into pellets, and bituminous coal is used as a reducing agent. The pellets were roasted at 1050°C for 45 minutes, and the cooled reduced pellets were crushed, placed in a ball mill and ground to -200 mesh at a pulp concentration of 50% to account for 95%, and the pulp was magnetically separated under a magnetic field strength of 0.1T. Obtained iron grade 90.78%, Al 2 o 3 Content 0.98%, SiO 2 The metal iron powder with a content of 0.45% has an iron recovery rate of 93.85%.

Embodiment 3

[0012] Example 3: TFe content 47.69%, Al 2 o 3 Content 8.96%, SiO 2 The iron ore with a content of 4.30% is crushed and ground to -200 mesh, accounting for 75%. According to the mass percentage of 20% and 2.5%, sodium sulfate and sodium borate are respectively mixed into pellets, and bituminous coal is used as a reducing agent. The pellets were roasted at 1050°C for 60 minutes, and the cooled reduced pellets were crushed, placed in a ball mill and ground to -200 mesh with a pulp concentration of 60% to account for 90%, and the pulp was magnetically separated under a magnetic field strength of 0.1T. Obtained iron grade 92.27%, Al 2 o 3 Content 0.76%, SiO 2 The metal iron powder with a content of 0.32% has an iron recovery rate of 93.03%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com