Biological treatment method for sewage water and waste gas generated by livestock and poultry cultivation

A biological treatment, livestock and poultry breeding technology, applied in the direction of biological water/sewage treatment, flotation water/sewage treatment, water/sludge/sewage treatment, etc., can solve the difficulties in design and implementation, high energy consumption and high operating costs , complex process and other issues, to achieve stable treatment effects, reduce auxiliary equipment and floor space, and achieve efficient and stable treatment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

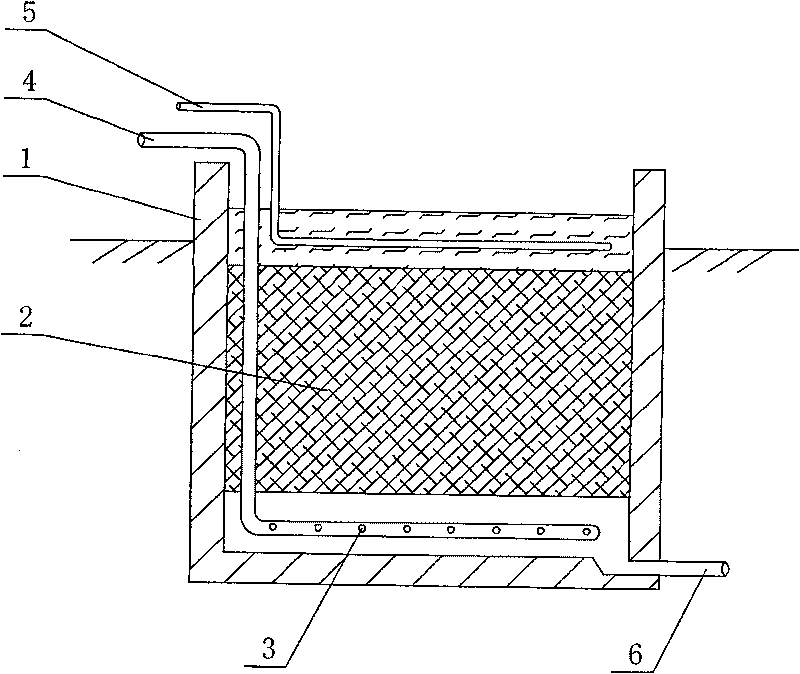

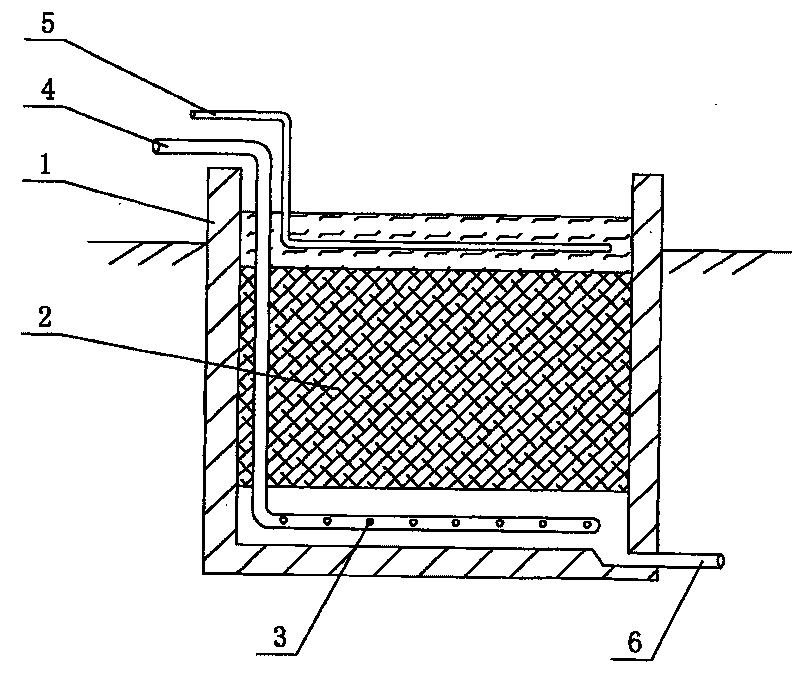

[0015] Specific implementation mode one: combine figure 1 The present embodiment will be described. This embodiment is composed of a bed body 1, a filter bed packing layer 2, an exhaust gas input pipeline 4, a sewage spray pipeline 5 and a sewage discharge pipeline 6. The exhaust gas input pipeline 4 is arranged in the bed body 1, and There are air holes 3 on the pipe wall of the exhaust gas input pipeline 4 in the bottom horizontal section, and a filter bed packing layer 2 is arranged above the exhaust gas input pipeline 4 in the bottom horizontal section of the bed body 1, and the filter bed packing layer 2 is made of wood chips or pottery. Granules are used as filler, and the filler specification (diameter or side length) is 4-6 mm. A sewage spray pipeline 5 is arranged above the filter bed filler layer 2, and a sewage discharge pipeline 6 is arranged at the bottom of the bed body 1.

[0016] The treatment unit combines liquid treatment and waste gas treatment in one.

specific Embodiment approach 2

[0017] Specific embodiment two: the steps of this embodiment method are as follows:

[0018] Step 1, using the biological treatment device of Embodiment 1;

[0019] Step 2. Pre-sedimentation and flotation separation of sewage pollutants produced by livestock and poultry breeding. The pre-sedimentation adopts the sedimentation device commonly used in the water treatment process to remove a large amount of solid matter such as feces in the wastewater; the flotation adopts an air flotation separation device , the purpose is to remove the suspended solid particles in the wastewater after pre-sedimentation, the separated solid particles are used as compost, and the pretreated sewage is introduced into the sewage spray pipeline 5 of the biological treatment device;

[0020] Step 3, collecting waste gas and inputting it into the biological treatment device through the waste gas input pipeline 4 of the biological treatment device;

[0021] Step 4, put the residual activated sludge of...

specific Embodiment approach 3

[0024] Specific embodiment three: The time for biofilm generation in step four of this embodiment is 30 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com