Method for preparing modified poly-epoxy succinic acid derivative

A technology of polyepoxysuccinic acid and derivatives, applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc., to achieve good biodegradability and prevent insoluble polymer-calcium coagulation. glue, the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

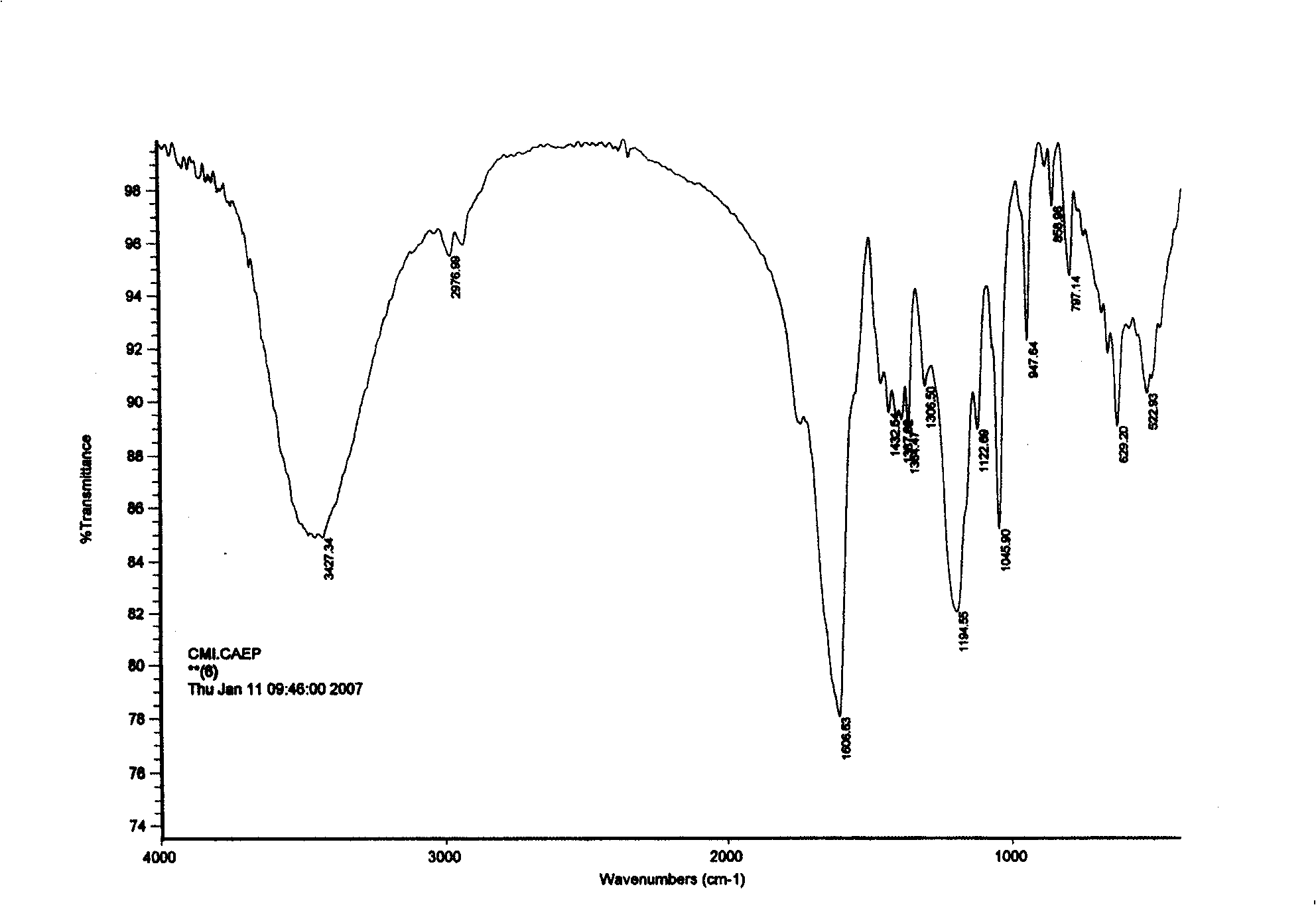

Image

Examples

Embodiment 1

[0016] Add 9.8g of maleic anhydride and water into a 4-neck flask equipped with a thermometer, condenser, dropping funnel and constant speed stirring device, stir to make it completely dissolve in water, add 8.1g of 2-acrylamide-2-formazine Propanesulfonic acid, react at 80°C for 2 hours, after the reaction is completed, control the solution temperature at 50°C-55°C, add an appropriate amount of sodium hydroxide solution dropwise, pay attention to controlling the rate of addition, and finish the dropwise addition within 30 minutes . Heating, when the temperature of the solution reaches 60°C, add the inorganic filtration metal mixed catalyst according to 2.1% of the amount of maleic anhydride, and then continuously add the hydrogen peroxide solution whose total amount is 1.4 times that of maleic anhydride, and dropwise Sodium hydroxide, keep the pH value of the solution between 6 and 6.5, after the dropwise addition, heat to 70°C, react at this temperature for 1.5 hours, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com