Double-frequency magnetic response negative magnetoconductivity metal compound structure material and production method thereof

A metal composite structure, negative magnetic permeability technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problem of not realizing dual-band magnetic response, unrealizable, and difficult to achieve technically.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

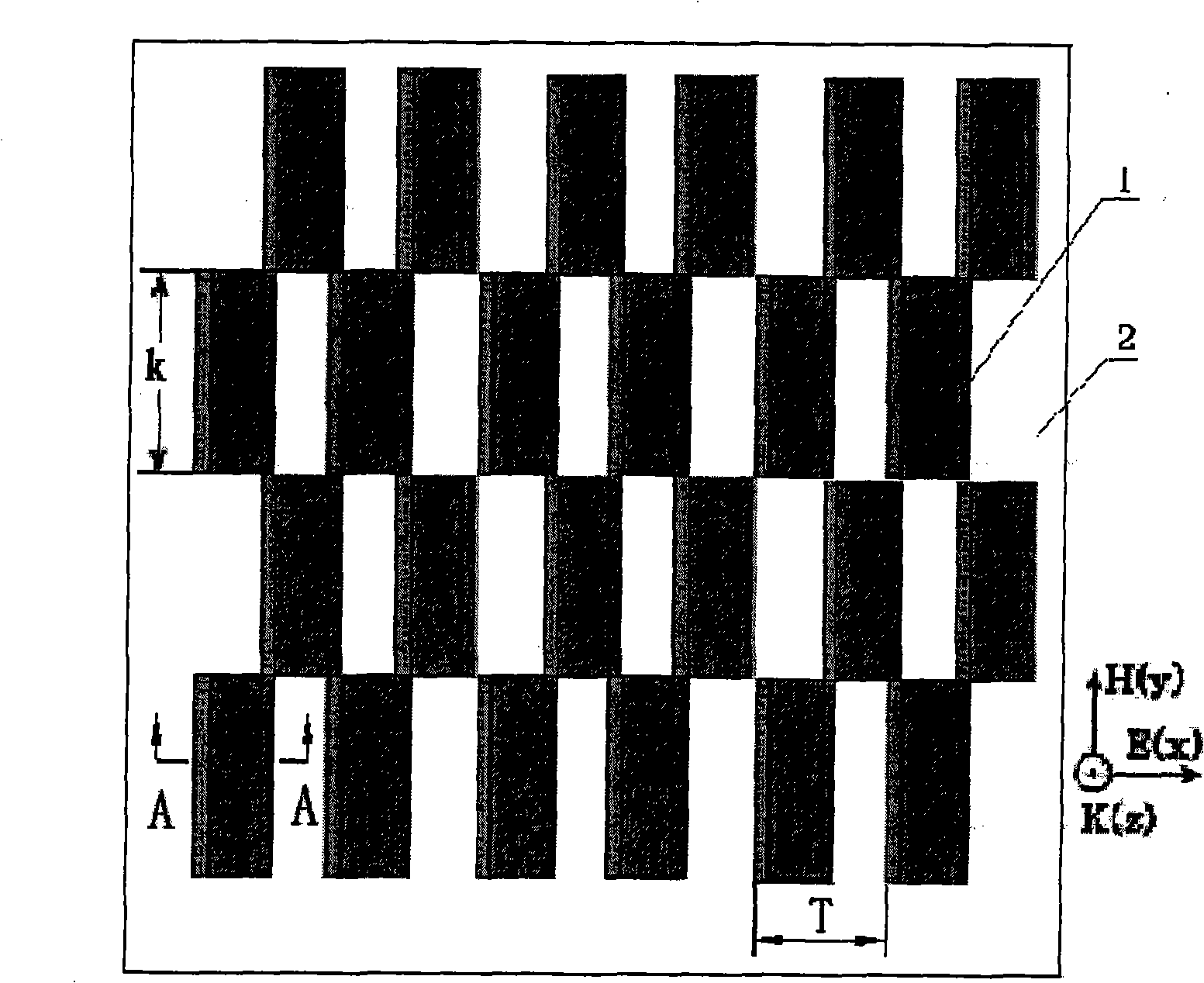

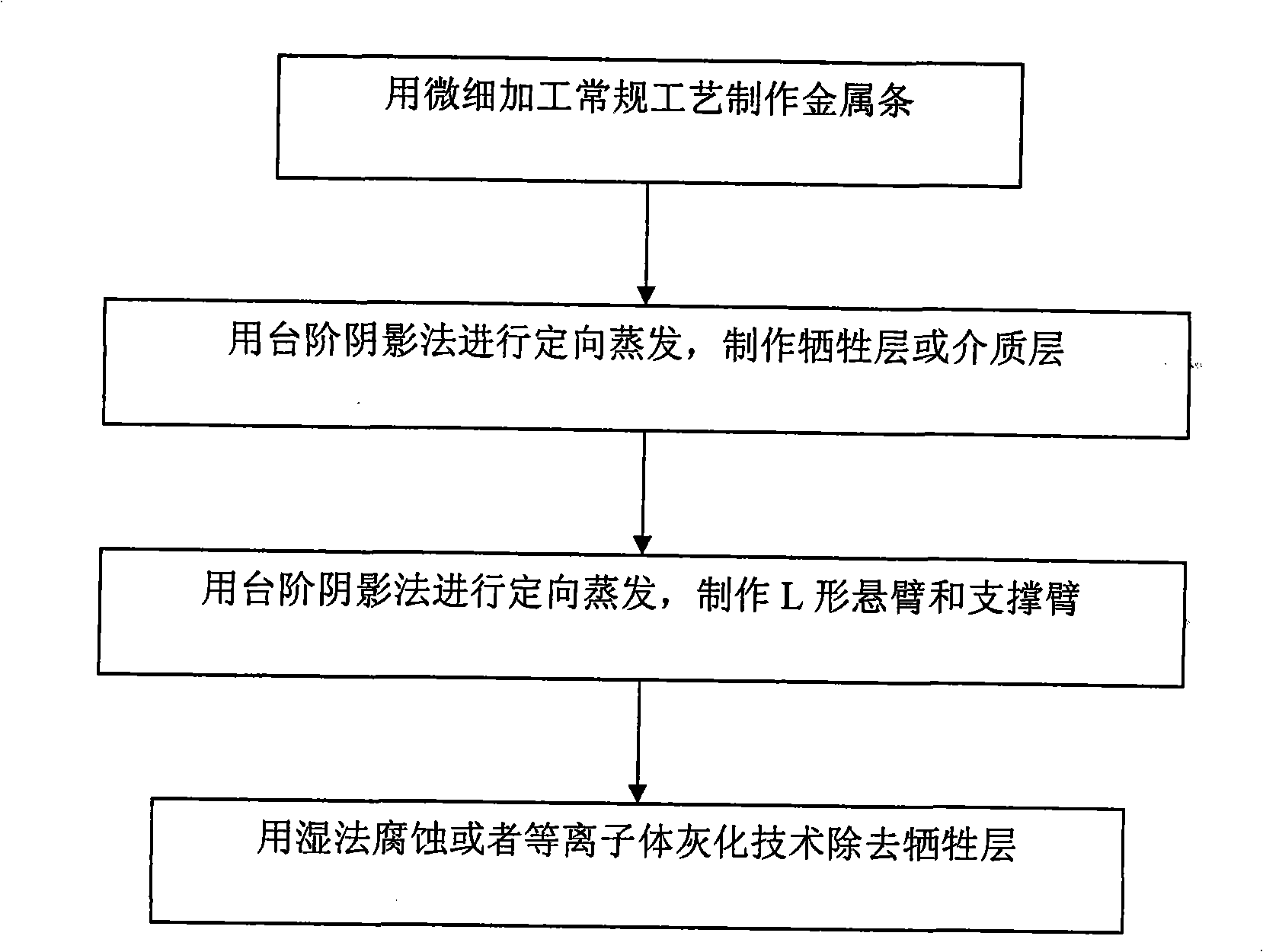

[0030] The dual-frequency magnetic response negative permeability metal composite structure material of this embodiment is composed of a first metal composite structure group 1 and a substrate 2 , and the first metal composite structure group 1 is fabricated on the substrate 2 .

[0031] like figure 1 Shown is an enlarged schematic diagram of a local structure of the embodiment of the present invention, which is composed of the first metal composite structure group 1 and the substrate 2, the first metal composite structure group 1 is a composite structure with a length k=300nm in the longitudinal direction, and it is according to the transverse period. T=400nm, multiple groups and multiple rows are staggeredly arranged on the base 2, and the base 2 is a transparent quartz substrate.

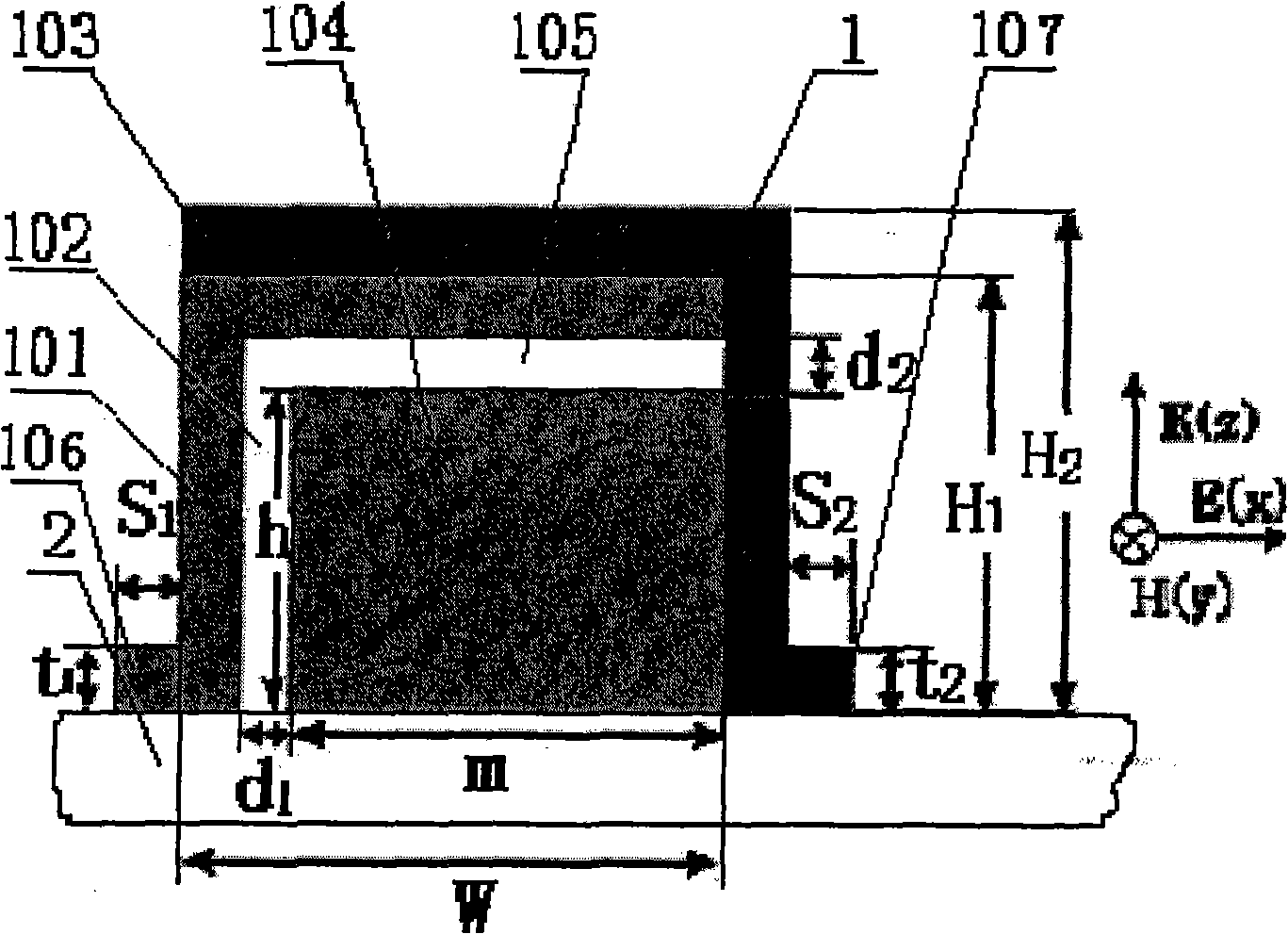

[0032] like figure 2 Shown is an enlarged view of the A-A sectional structure of the first metal composite structure group 1 in Embodiment 1, which consists of an L-shaped cantilever 101, a sup...

Embodiment 2

[0041] The dual-frequency magnetic response negative permeability metal composite structure material of this embodiment is composed of a second metal composite structure group 3 and a substrate 2 , and the second metal composite structure group 3 is fabricated on the substrate 2 .

[0042] like Figure 4 Shown is the enlarged schematic diagram of the partial structure of the second embodiment of the present invention, which is composed of the second metal composite structure group 3 and the substrate 2, the second metal composite structure group 3 is a structure whose Z longitudinal length is infinite, and it follows the transverse period T= 400nm are arranged on the substrate 2, which is also a transparent quartz substrate.

[0043] like Figure 5 Shown is an enlarged view of the B-B sectional structure of the second metal composite structure group 3 of Embodiment 2, which consists of an L-shaped cantilever 301, a first dielectric layer 302, a second dielectric layer 303 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com