Airtight transporting blending metering system and method for powder culture medium

A technology of airtight transportation and culture medium, which is applied to conveyors, tissue culture, and bulk material transportation. It can solve problems such as low production efficiency, high labor intensity, and hidden dangers, and achieve improved batch production capacity, reduced labor intensity, and reduced The effect of inter-assay differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings.

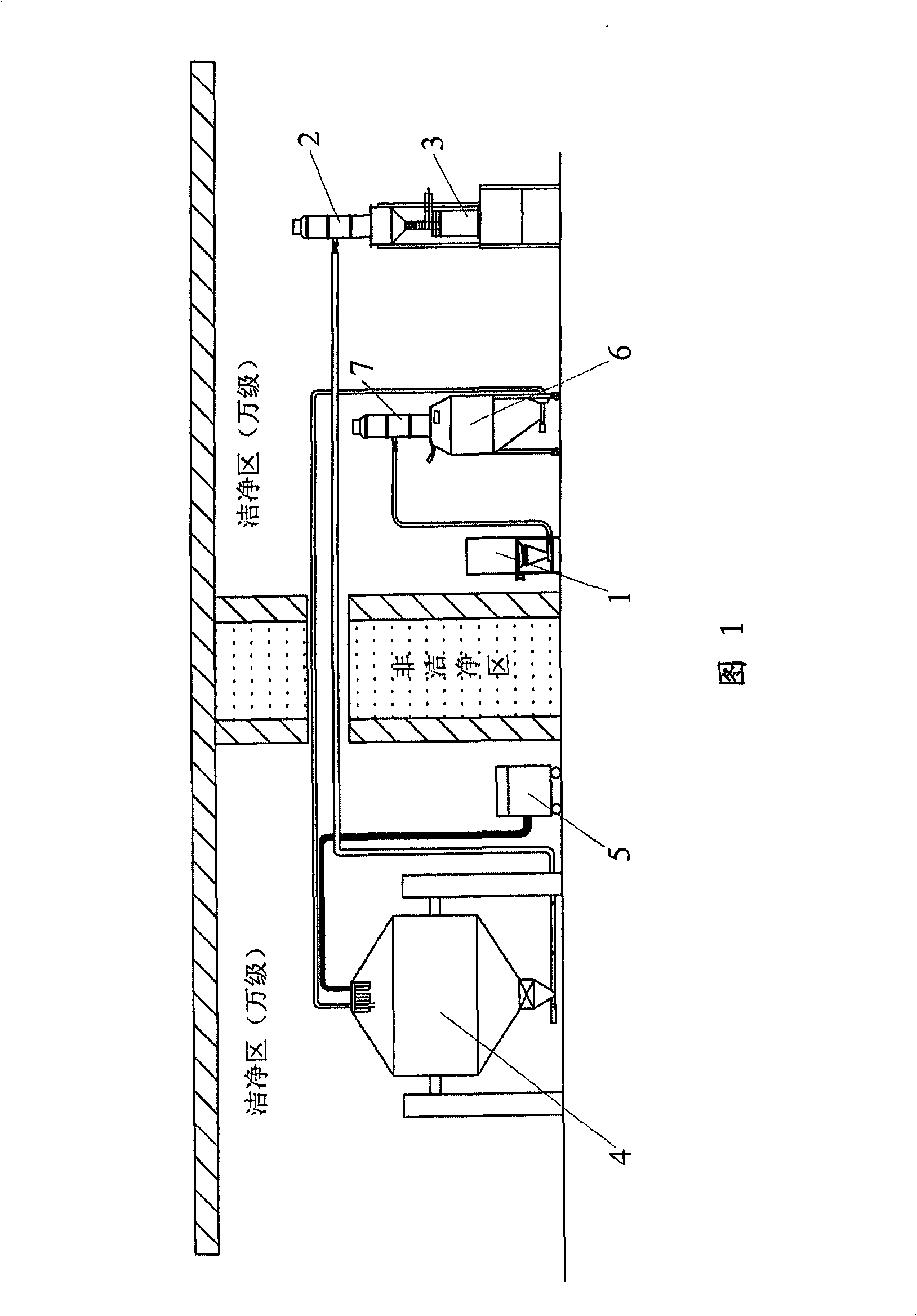

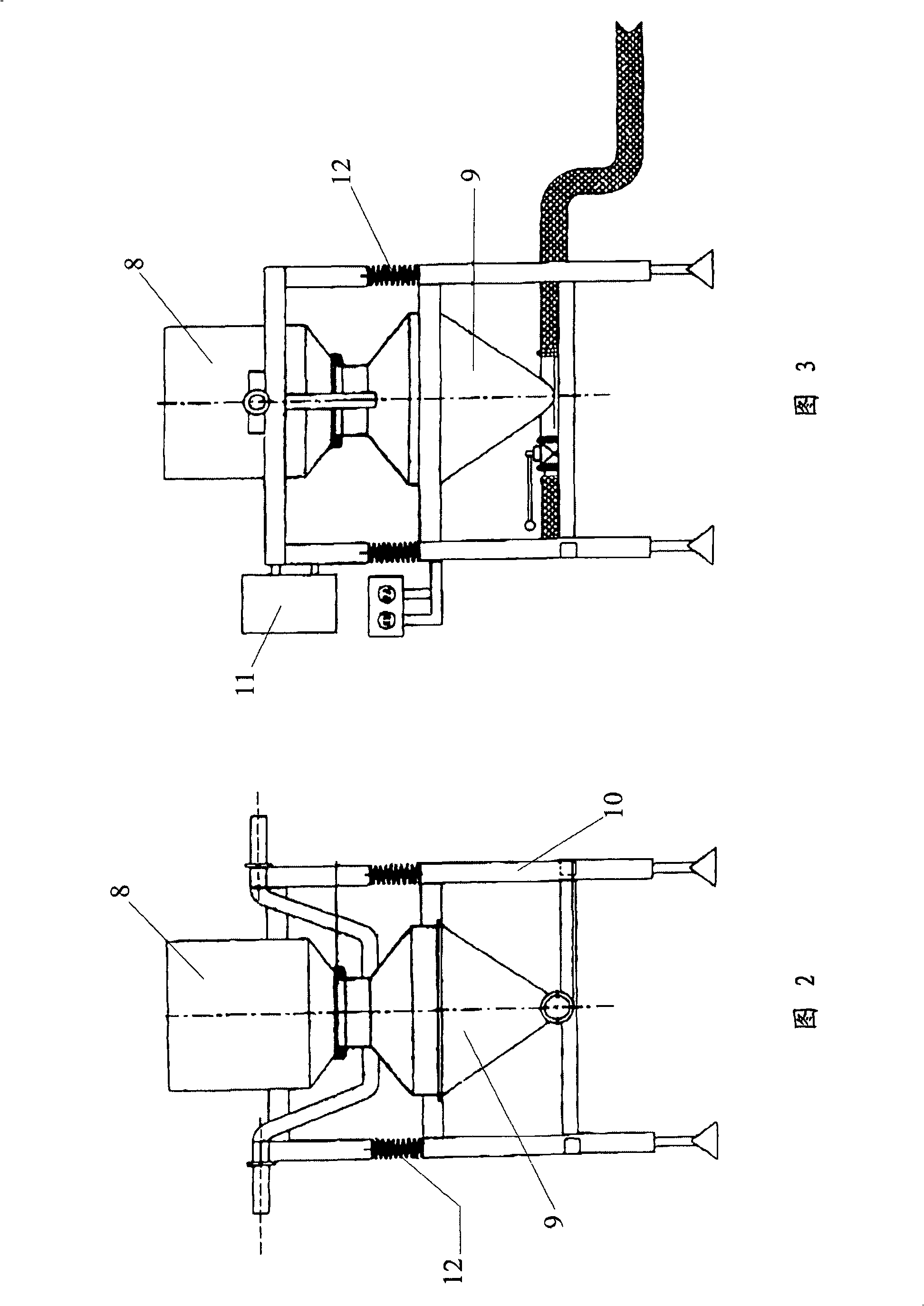

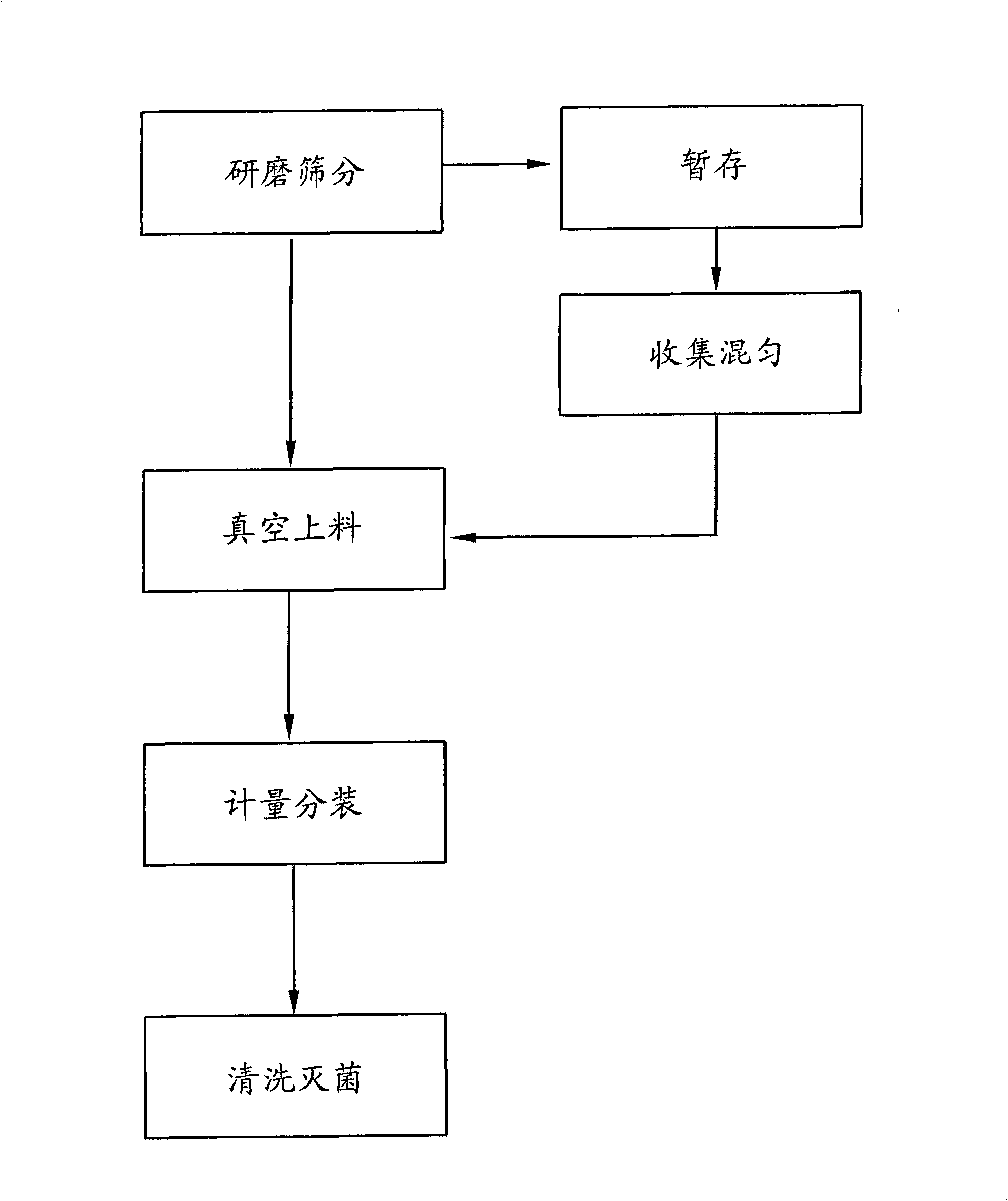

[0029] As shown in Figure 1, it is a kind of airtight conveying and mixing metering system of powder culture medium provided by the present invention, utilizes grinding and screening device 1 to grind and screen the powder culture medium, and grinding and screening device 1 specifically includes grinding container 8, Screening lower hopper 9, vibrating support 10 and vibrating motor 11, as shown in Figure 2 and Figure 3; Grinding container 8 is detachably inverted and fixed on the feeding port of sieving lower hopper 9, so that the powder culture medium in grinding container 8 It falls in the lower hopper for screening 9; the fixed grinding container 8 and the lower hopper for sieving are detachably fixed on the vibrating support 10. In this example, the lower hopper for sieving is detachably fixed on the vibrating On the bracket 10, the fixing method can adopt any s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com