Preparation method of up-conversion fluorescent material with controllable grain diameter

A fluorescent material and particle size technology, applied in the field of nanomaterials, can solve problems such as affecting the accuracy and sensitivity of detection, high requirements for detection instruments, and unclean running boards, and achieve the effect of uniform morphology, uniform particle size, and improved sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A method for preparing an up-conversion fluorescent material with a controllable particle size, comprising the following steps:

[0030] Step 1, adding rare earth chloride or rare earth acetic acid compound into the container, then adding oleic acid, and then heating to obtain a clear and transparent rare earth-oleic acid precursor; adding sodium hydroxide and ammonium fluoride into a low-boiling organic solvent , to obtain a clear and transparent sodium fluoride precursor;

[0031] Step 2, adding octadecene to the rare earth-oleic acid precursor of step 1, and then heating;

[0032] Step 3, the rare earth oleic acid precursor of step 2 is cooled down, the sodium fluoride precursor is added to the rare earth oleic acid precursor, and then the reactant is heated under the protection of argon and kept for reaction, and after the reaction is completed, the reaction mother liquor Cooling, then centrifuging to precipitate the product out of the solution, then washing, preci...

Embodiment 1

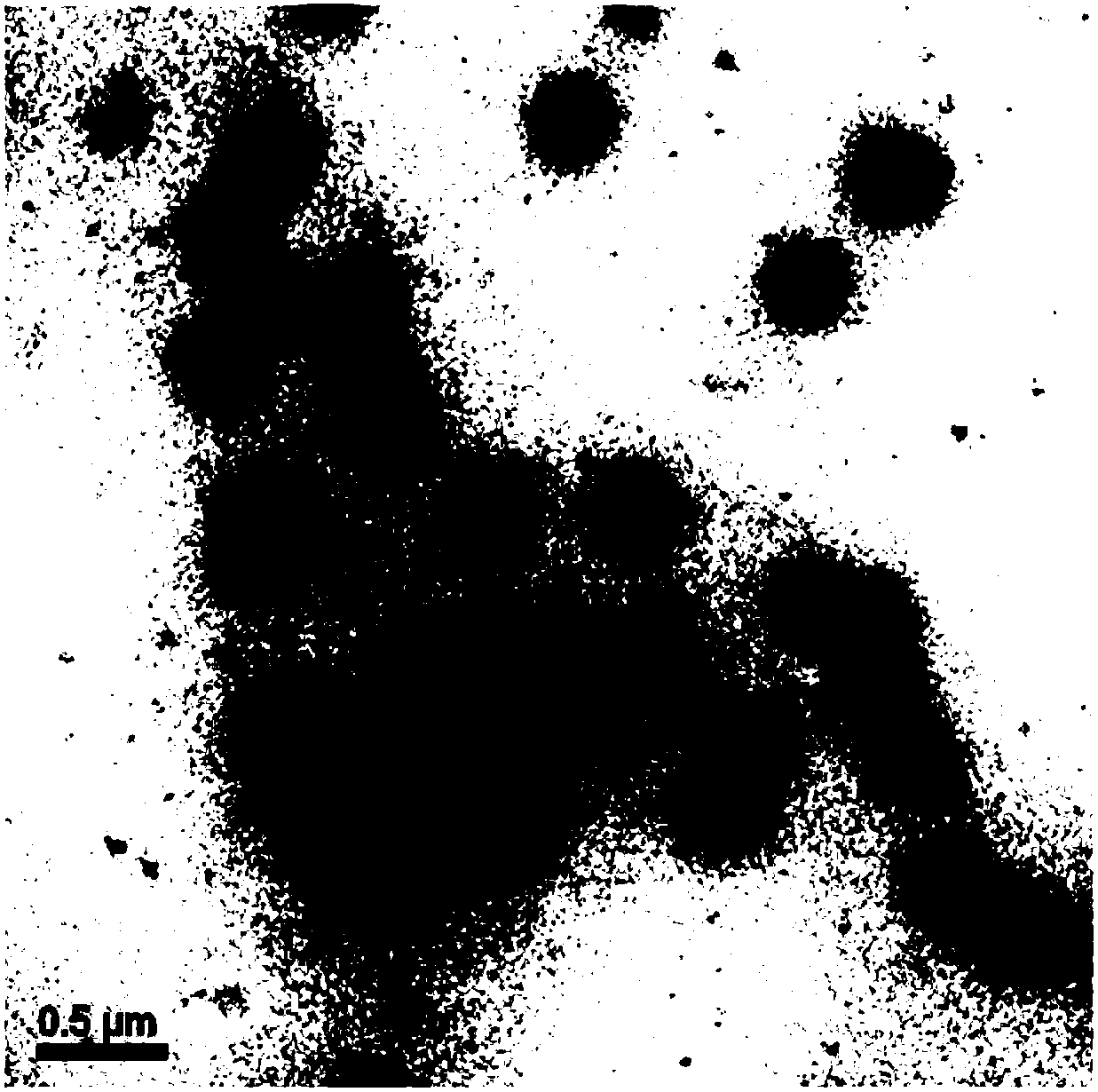

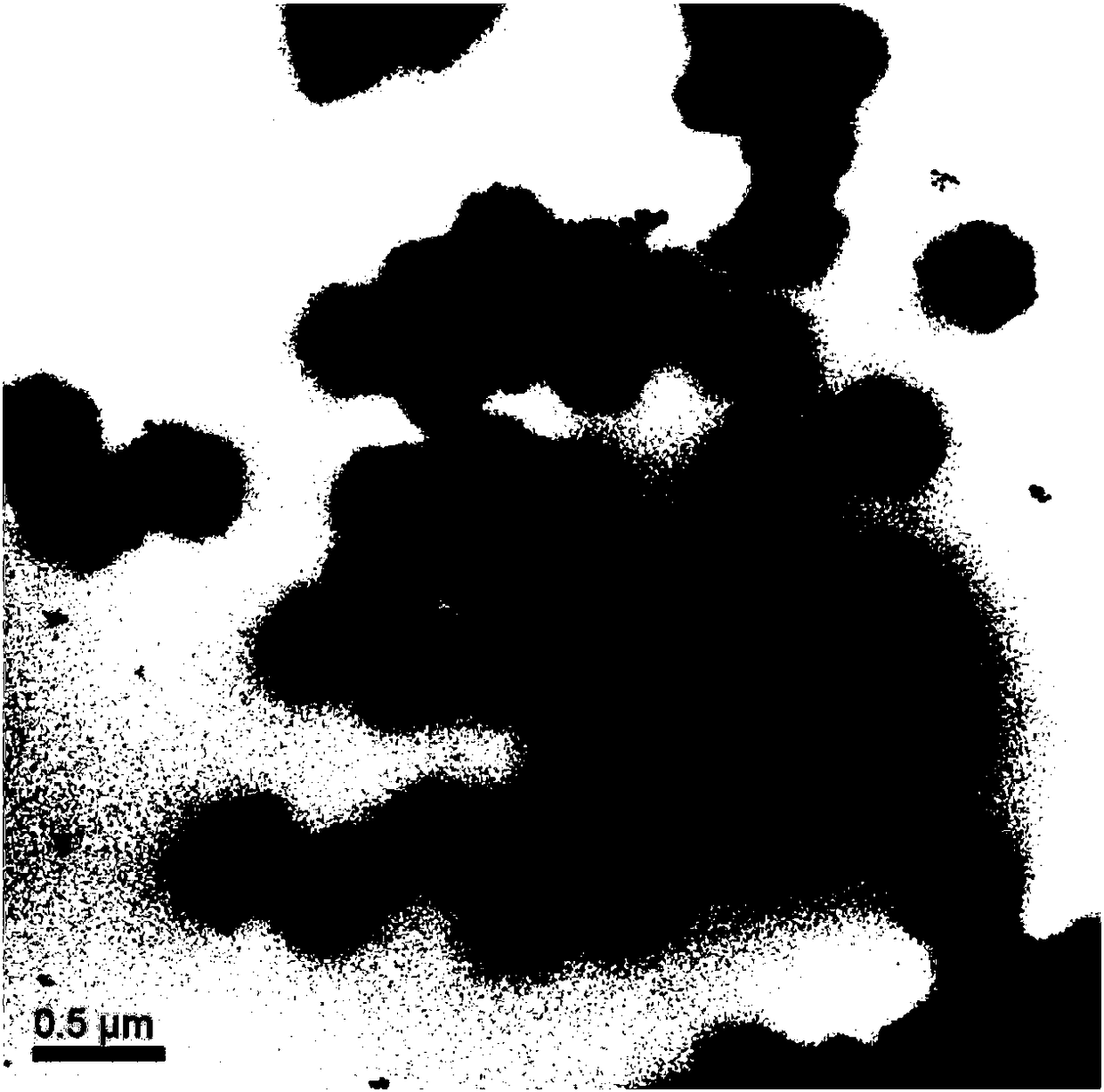

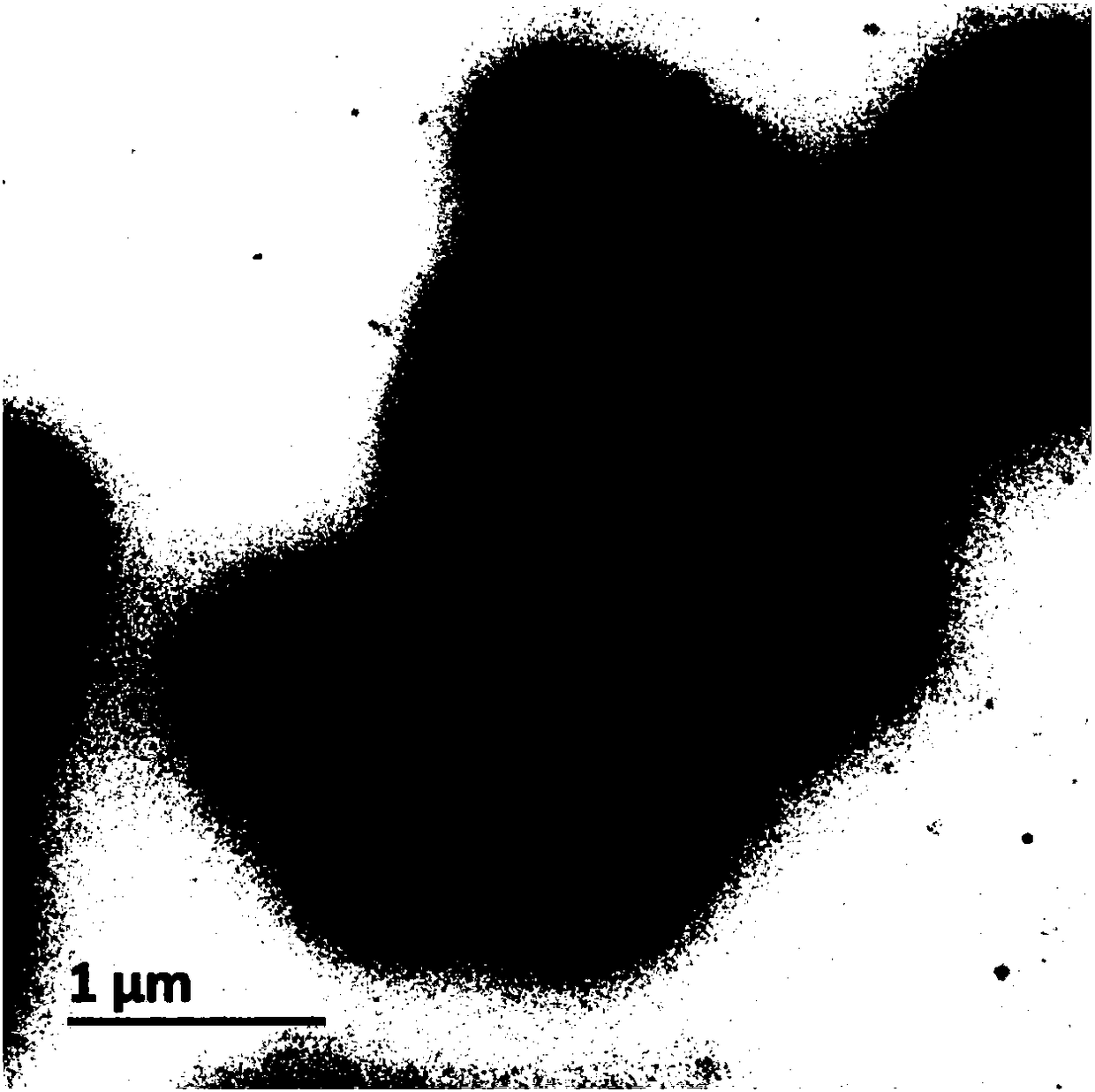

[0036] like Figures 1 to 3 As shown in the figure, a method for preparing an up-conversion fluorescent material with controllable particle size is characterized by comprising the following steps:

[0037] Step 1, add 2 mmol of rare earth chloride in a certain proportion, which contains 20% ytterbium (Yb), 2% erbium (Er) and 78% lutetium (Lu), into a three-necked round bottom flask, and then add 8 ml of oil Acid (OA), heated to 140 degrees Celsius and held for 2 minutes under magnetic stirring to finally obtain a clear and transparent rare earth-oleic acid precursor; 5 mmol of sodium hydroxide (NaOH) and 8 mmol of ammonium fluoride (NH4F) were added into 10 ml of methanol, and sonicated to obtain a clear and transparent sodium fluoride precursor;

[0038] Step 2, adding 20ml of octadecene (ODE) to the rare earth-oleic acid precursor of step 1, heating to 140 degrees Celsius under magnetic stirring and holding for 2 minutes;

[0039] In step 3, after the preparation of the ra...

Embodiment 2

[0044] This example is basically the same as Example 1, except that in Example 2, the rare earth chloride in step 1 contains 20% ytterbium (Yb), 2% erbium (Er) and 78% yttrium (Y), oleic acid The mass ratio to rare earth chloride is 10:1; the mass ratio of octadecene to rare earth-oleic acid precursor in step 2 is 100:1; in step 3, the reactant is heated to 300 under the protection of high-purity argon gas Celsius and incubated for 60 minutes.

[0045] The average particle size of the obtained nanoparticles was 32.7 nm, the standard deviation of the particle size within the batch was 1.8, and the standard deviation of the particle size between the batches was 2.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com