Polysilicate aluminum sulphate flocculant, preparation process and use thereof

A preparation process and flocculant technology, which is applied in the field of polymer flocculant synthesis, can solve problems such as poor product reproducibility and difficulty in practical application, and achieve high molecular weight, good product reproducibility, and uniform distribution of silicon and aluminum Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

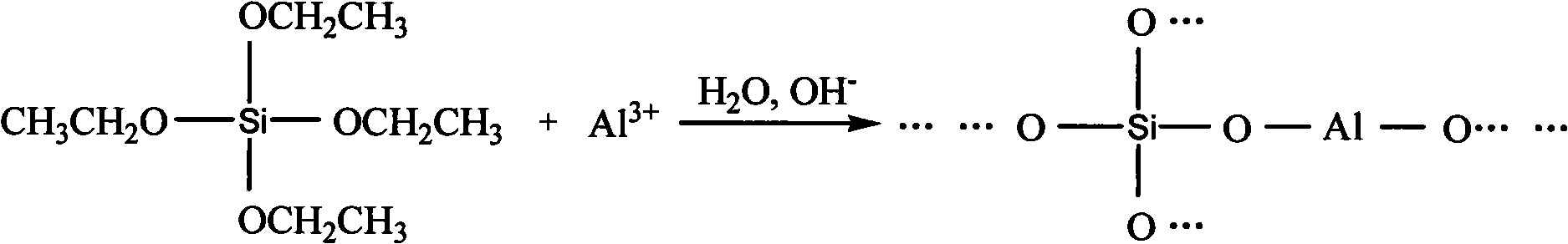

Method used

Image

Examples

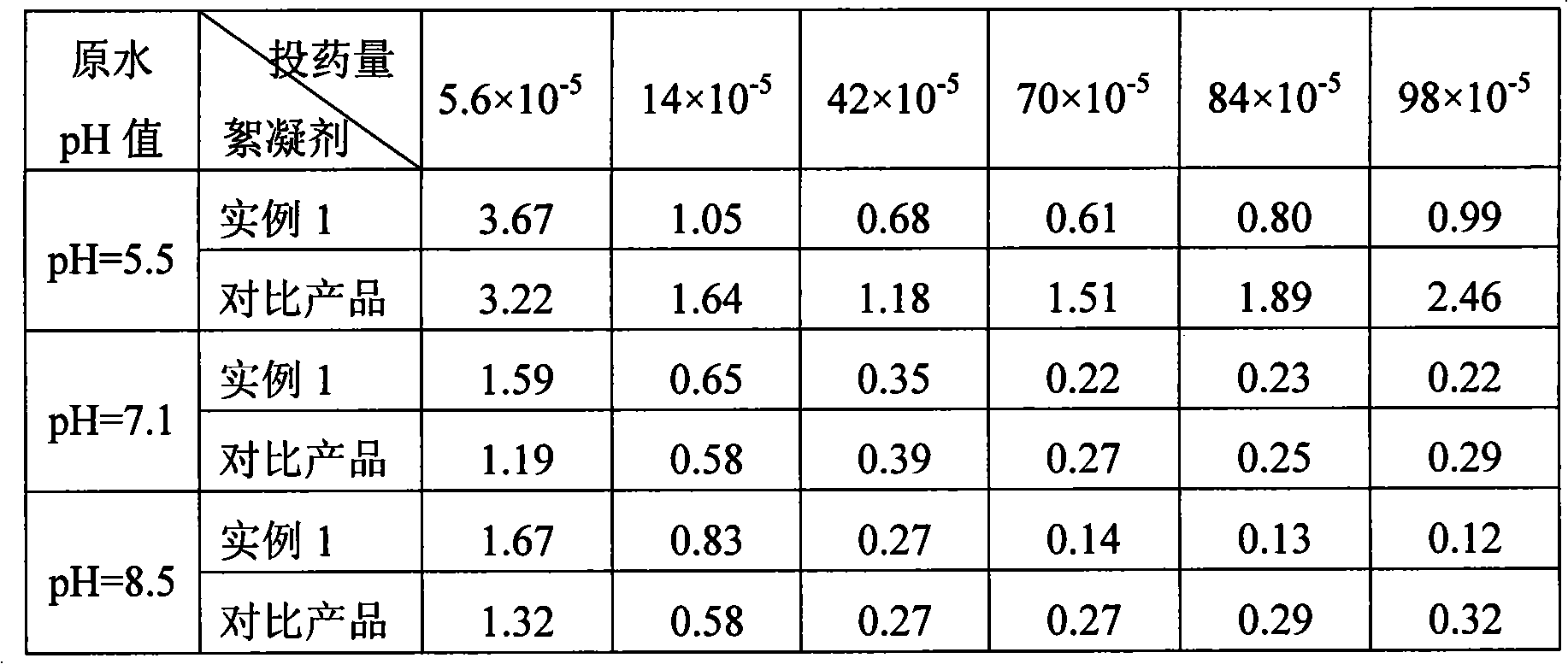

example 1

[0019] Polysilicon aluminum flocculant, the total aluminum concentration is 0.07mol / L, the Si / Al molar ratio is 0.2, the degree of alkalization B is 2.5, and the pH value is 3.8.

[0020] The preparation method is as follows:

[0021] At room temperature, add 50 mL of AlCl with a concentration of 0.25 mol / L in proportion to the three-necked flask 3 solution and 0.58mL of TEOS, then stirred rapidly at room temperature, and slowly added 125mL of NaOH solution with a concentration of 0.25mol / L to the required amount using a constant flow pump. 3 The ratio is 2.5, the reaction is complete after dropping, the obtained solution is left to stand until the reaction is complete, and the polysilicon aluminum flocculant is obtained after 24 hours.

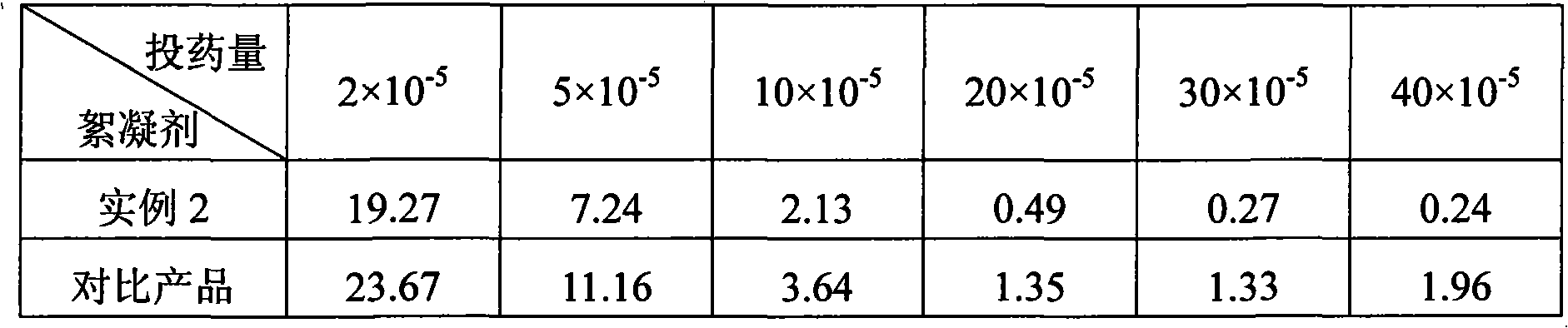

example 2

[0023] Polysilicon aluminum flocculant, the total aluminum concentration is 0.2mol / L, the Si / Al molar ratio is 0.4, the degree of alkalization B is 2.0, and the pH value is 3.5.

[0024] The preparation method is as follows:

[0025] Add 50 mL of AlCl with a concentration of 1.0 mol / L to the three-necked flask according to the predetermined Si / Al molar ratio. 3 solution and 4.61 mL of TEOS. Then stir rapidly at room temperature, and use a constant flow pump to slowly add 200 mL of NaOH solution with a concentration of 0.5 mol / L to the predetermined B value. 3 The ratio was 2.0, and the titration time was 3 hours. The resulting solution was allowed to stand until the reaction was complete. After 2 days, a product with a total aluminum concentration of 0.2 mol / L was obtained.

[0026] Application Example 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com