Method for continuous preparation of highly effective cement additive

A cement admixture, high-efficiency technology, applied in the field of preparation of high-efficiency cement admixture, continuous preparation of high-efficiency cement admixture, can solve the problems of inability to increase the early strength of cement, adverse environmental effects, high production costs, etc., to achieve strength improvement and reduce production costs , the effect of air content improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

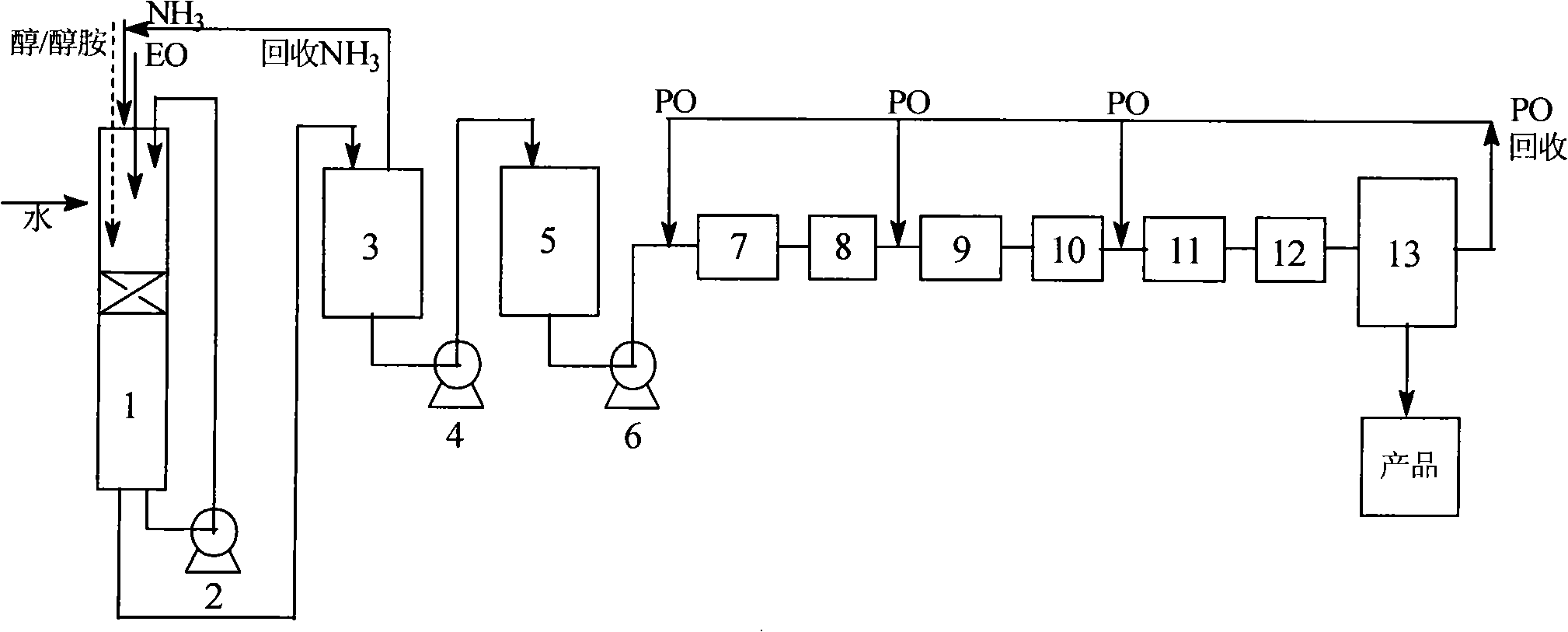

[0041] Add 1300kg of DEIPA to the 5000L continuous reactor 1, heat up and open the external circulation pump 2, when the liquid phase temperature reaches 70°C, spray 12kg / min water flow, 8kg / min ammonia flow and 4kg / min EO stream, control reaction pressure 1.8-2.2MPa, reaction temperature 80-100℃, residence time 1.0 hour. Keep the liquid level of the stream in the continuous reactor 1 at 2000-2200L, part of the stream is continuously sent to the flash tower 3, the tower pressure is kept between 0.4-0.9MPa, the temperature is controlled at 90-110°C, and deamination is carried out. Ammonia content 2.50% in the stream after ammonia, this stream flows through tundish 5, and sampling detects, and the content that gets MEA and DEA is respectively 44.0% and 42.2%, and 7.5kg / min PO stream is by 40%, 35%, The proportion of 25% is divided into three sections, and the stream after deamination is continuously passed into static mixers 7, 9 and 11 at the same time to make them fully mixed....

Embodiment 2

[0043]Add 800kg DEIPA and 500kg EDIPA to the 5000L continuous reactor 1, heat up and open the external circulation pump 2, when the liquid phase temperature reaches 55°C, spray 10kg / min water stream and 10kg / min ammonia from the top of the continuous reactor 1 flow and 4kg / min EO flow, the reaction pressure is controlled at 1.9-2.5MPa, the reaction temperature is 65-100°C, and the reaction residence time is 1.1 hours. Keep the liquid level of the stream in the continuous reactor 1 at 2000-2200L, part of the stream is continuously sent to the flash tower 3, the pressure is kept between 0.3-0.6MPa, the temperature is controlled at 85-110°C, deamination is carried out, and the deamination is analyzed Ammonia content 3.42% in the stream after, this stream flows through tundish 5, sampling detects, and the content that gets MEA and DEA is respectively 43.9% and 42.0%, and 8kg / minPO stream is by 30%, 30%, 40% ratio Divided into three sections and continuously fed into static mixers ...

Embodiment 3

[0045] Add 1300kg EDIPA to the 5000L continuous reactor 1, heat up and open the external circulation pump 2, when the liquid phase temperature reaches 50°C, spray 8kg / min water flow, 12kg / min ammonia flow and 4kg / min EO stream, control reaction pressure 2.3-3.2MPa, reaction temperature 75-100°C, reaction residence time 2.3 hours. Keep the liquid level of the stream in the continuous reactor 1 at 2000L, and part of the stream is continuously sent to the flash tower 3. The pressure of the flash tower is kept between 0.5 and 0.7 MPa, and the temperature is controlled at 75 to 100°C for deamination and analysis. Ammonia content is 2.72% in the stream after ammonia, this stream flows through tundish 5,, sampling detects, and the content that gets MEA and DEA is respectively 48.0% and 38.1%, the 8.6kg / min PO stream is by 35%, 35% % and 30% are divided into three sections and are continuously fed into static mixers 7, 9 and 11 at the same time as the deaminated stream to make them f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com