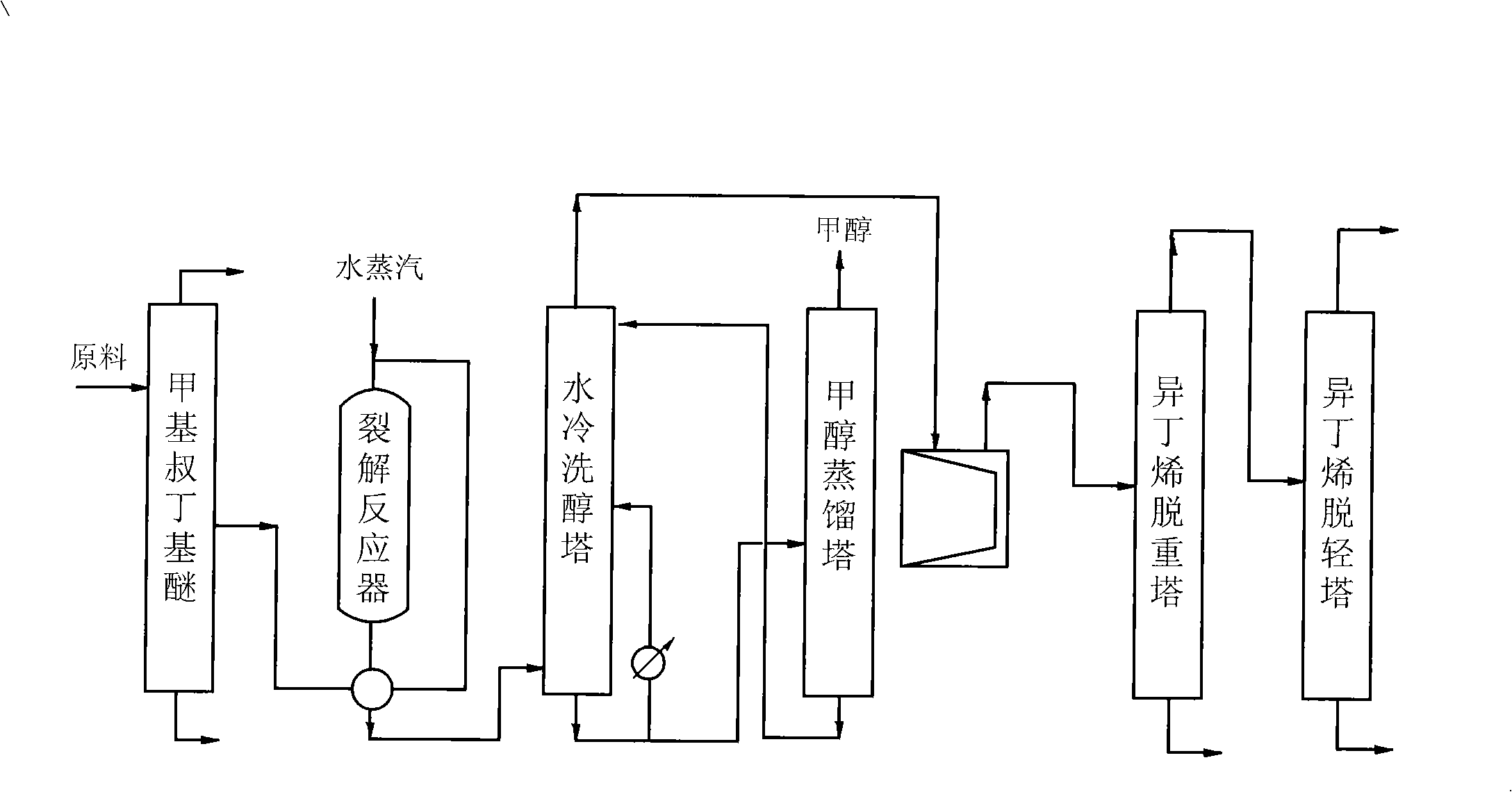

Method for preparing isobutene by cracking methyl tert-butyl ether

A technology of methyl tert-butyl ether and isobutene, which is applied in the chemical industry, can solve the problems of lower real yield of isobutene, and achieve the effects of low cost, increased production capacity, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The cracking reaction of methyl tert-butyl ether is carried out in a low-bed tube reactor with a tube length of 3.5 meters, using ML-01 catalyst, and a specific gravity of 0.5g / cm 3 , A white spherical silica catalyst with a diameter of 3-4mm, the height of the catalyst bed is 2 meters, the reaction temperature is 240-270°C, the reaction pressure is 0.08MPa, and the molar ratio of water to methyl tert-butyl ether is 1.0, Other operating conditions and results are shown in Table 1.

[0025] Table 1. Operating conditions and results

[0026] project

Embodiment 2

[0027] Example 2, the cracking reaction of methyl tert-butyl ether is carried out in a low bed tube reactor, the tube length is 3.5 meters, ML-01 catalyst is selected, and the stack specific gravity is 0.45g / cm 3 , A white spherical silica catalyst with a diameter of 3-4 mm, the height of the catalyst bed is 2 meters, the reaction temperature is 240-270 ° C, the reaction pressure is 0.05 MPa, and the molar ratio of water to methyl tert-butyl ether is 2.0, Other operating conditions and results are shown in Table 2.

[0028] Table 2. Operating conditions and results

[0029] project

Embodiment 3

[0039] The methyl tert-butyl ether cracking reaction is carried out in a low-bed tube reactor with a tube length of 3 meters, using ML-01 catalyst, and a specific gravity of 0.45g / cm 3 , White spherical silica series catalysts with a diameter of 3-4mm, the height of the catalyst bed is 2 meters, and the liquid phase space velocity is 6h -1 , the reaction temperature is 240-270°C, the reaction pressure is 0.06MPa, and the molar ratio of water to methyl tert-butyl ether is 3.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com