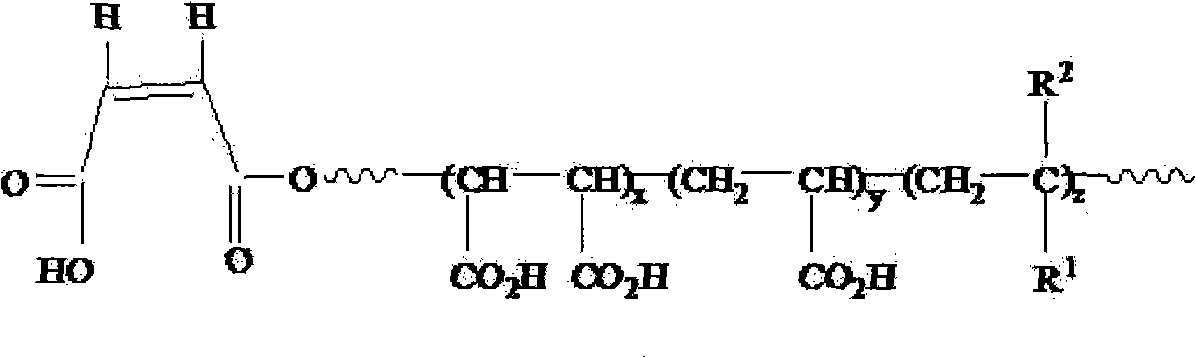

Method for preparing co-polymerized polyocarboxy acid oxymethylene-free anti-creasing finish agent

An anti-wrinkle finishing agent, polycarboxylic acid technology, used in fiber processing, textiles and papermaking, etc., can solve the problems of not mentioning the influence of polymer main chain end groups on the properties of polymers, and achieve both cost and The use effect, the production process is simple, and the expensive effect is overcome

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) 48g maleic anhydride was mixed with 200g mass percent 30% hydrogen peroxide in a reaction flask, and reacted for 20-40 minutes at 40°C to generate peroxidized maleic anhydride as an initiator solution;

[0020] (2) Heat up to 100°C, keep stirring and reflux, continuously add 96g of acrylic acid aqueous solution dropwise from the dropping funnel, and complete the dropwise addition within 2 hours;

[0021] (3) Keep the reflux reaction for 2 hours, and cool down to 40° C. to obtain a colorless or light yellow transparent liquid.

Embodiment 2

[0023] With embodiment 1, the addition amount of hydrogen peroxide is 160g, all the other conditions are constant.

Embodiment 3

[0025] With embodiment 1, the addition amount of hydrogen peroxide is 240g, all the other conditions are constant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com