Method for treating indium stannum smoke raw material

A treatment method and raw material technology, applied in the field of indium tin fume raw material treatment, to achieve the effect of effective method, simple operation and effective separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

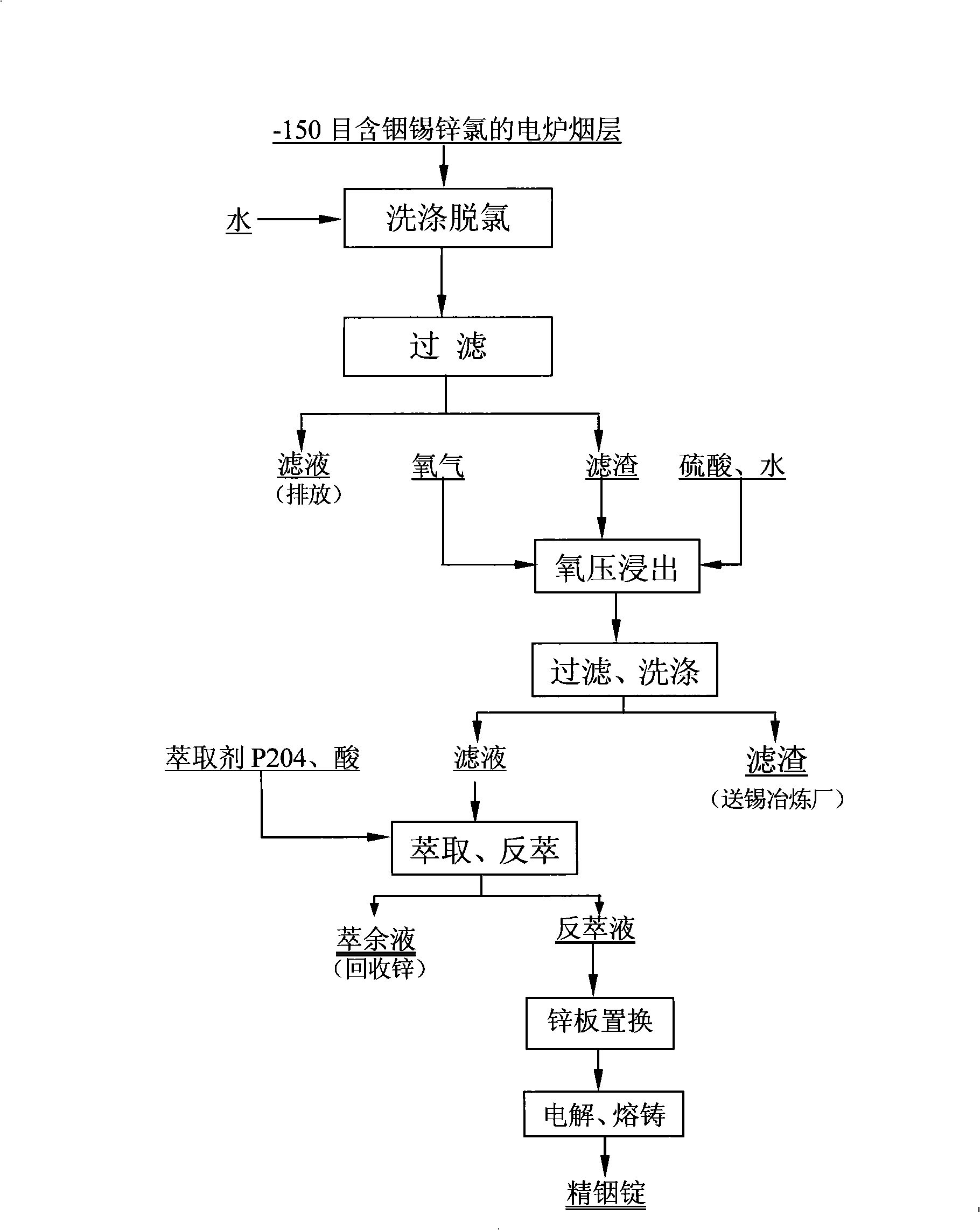

Method used

Image

Examples

Embodiment 1

[0018] A batch of indium-containing electric furnace smelting dust, containing 0.49% indium, 16.28% zinc, 19.57% tin, and 47.5% chlorine, was leached with water at normal temperature and pressure, the liquid-solid ratio was 4:1, and the leaching time was 10 minutes. The same conditions were used for the second time. After leaching, filtering, and drying the filter residue, it contains 0.702% indium, 21.4% zinc, 32.93% tin, and 0.85% chlorine; the filtrate indium is less than 0.01 g / L. Take 1000 grams of the above-mentioned dechlorinated materials (7.02 grams of indium, 329 grams of tin, and 214 grams of zinc) and add them to a pressure titanium kettle, add 4 liters of sulfuric acid with a concentration of 20%, and heat and pressure leaching with oxygen at a temperature of 160-170 ℃, the pressure in the kettle is 0.7-0.8MPa, the leaching reaction time is 3 hours, filter after leaching, add 4 liters of water to wash twice, filter, dry, weigh, the residue weight is 750 grams, samp...

Embodiment 2

[0020] A batch of indium-containing electric furnace smelting fumes, the raw material particle size is less than 150 mesh, containing 0.60% indium, 25.00% tin, and 0.15% chlorine, take 10 kg of the above materials and put them into a pressure titanium kettle, add 40 liters of sulfuric acid with a concentration of 25%, and pass through oxygen Heating and pressure leaching, temperature 165-175 °C, pressure in the kettle 0.8-0.9 MPa, leaching reaction time 4 hours, after leaching, filter, add 10 liters of water to wash twice, filter, dry, weigh, slag weight 7 Kilogram, sample analysis, containing 0.045% indium, 35.05% tin, the calculated indium leaching rate is 94.75%, tin leaching rate is 1.02%, and zinc leaching rate is 95.09%.

Embodiment 3

[0022] A batch of indium-containing electric furnace smelting dust, containing 0.32% indium, 15.6% tin, and 18.5% chlorine, was leached with water at normal temperature and pressure, the liquid-solid ratio was 4:1, and the leaching time was 10 minutes. The same conditions were leached twice, filtered, and the filter residue After drying, it contains 0.38% indium, 22.51% tin and 0.21% chlorine; the filtrate indium is less than 0.01 g / L. Take 10 kg of the above-mentioned dechlorinated materials (38 grams of indium and 2251 grams of tin) and put them into a pressure titanium kettle, add 40 liters of sulfuric acid with a concentration of 20%, and heat and pressure leaching with oxygen at a temperature of 160-170°C. Pressure 0.9-1.0MPa, leaching reaction time 3.5 hours, filter after leaching, add 10 liters of water to wash twice, filter, dry, weigh, slag weighs 7250 grams, sample analysis, containing 0.032% indium, 43.06% tin, It is calculated that the indium leaching rate is 93.89...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com