Double-frequency band lamination medium loading helical antenna

A medium-loaded, helical antenna technology, applied in antennas, resonant antennas, independent antenna unit combinations, etc., can solve the problem that the antenna cannot achieve dual-band operation, achieve good directivity and circular polarization performance, and reduce the impact , the effect of reducing the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

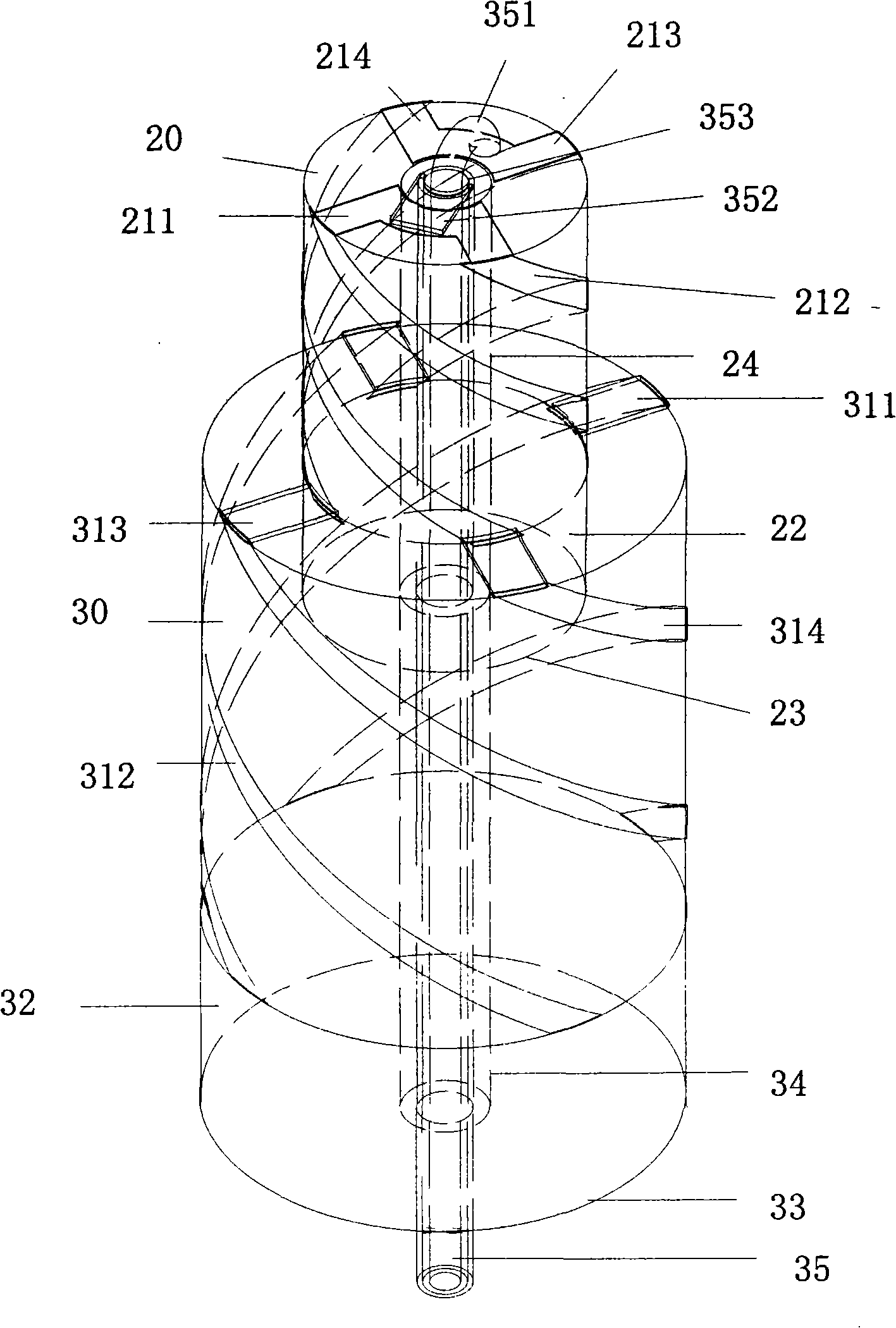

[0045] The specific structure of the antenna is as figure 1 As shown, the metal layer 22 on the columnar body 20 is all inserted into the top of the columnar body 30, and the two are closely attached to form an integral structure.

[0046] The radiating metal sheets 211, 212, 213, 214 extend in a helical path along the side of the columnar body 20, but they have different lengths. The pitches of the radiating metal sheets 211 and 213 are slightly larger than the pitches of the radiating metal sheets 212 and 214, so that The length of the radiating metal sheets 211 and 213 can be made to be 0.45λ 1 , slightly shorter than half the wavelength; the length of the radiating metal sheets 212 and 214 is 0.55λ 1 , slightly longer than half a wavelength, where λ 1 is the wavelength of the first working frequency band of the antenna; the radiating metal sheets 311, 312, 313, 314 extend along the side of the columnar body 30 in a helical path, but they have different lengths, and the p...

Embodiment 2

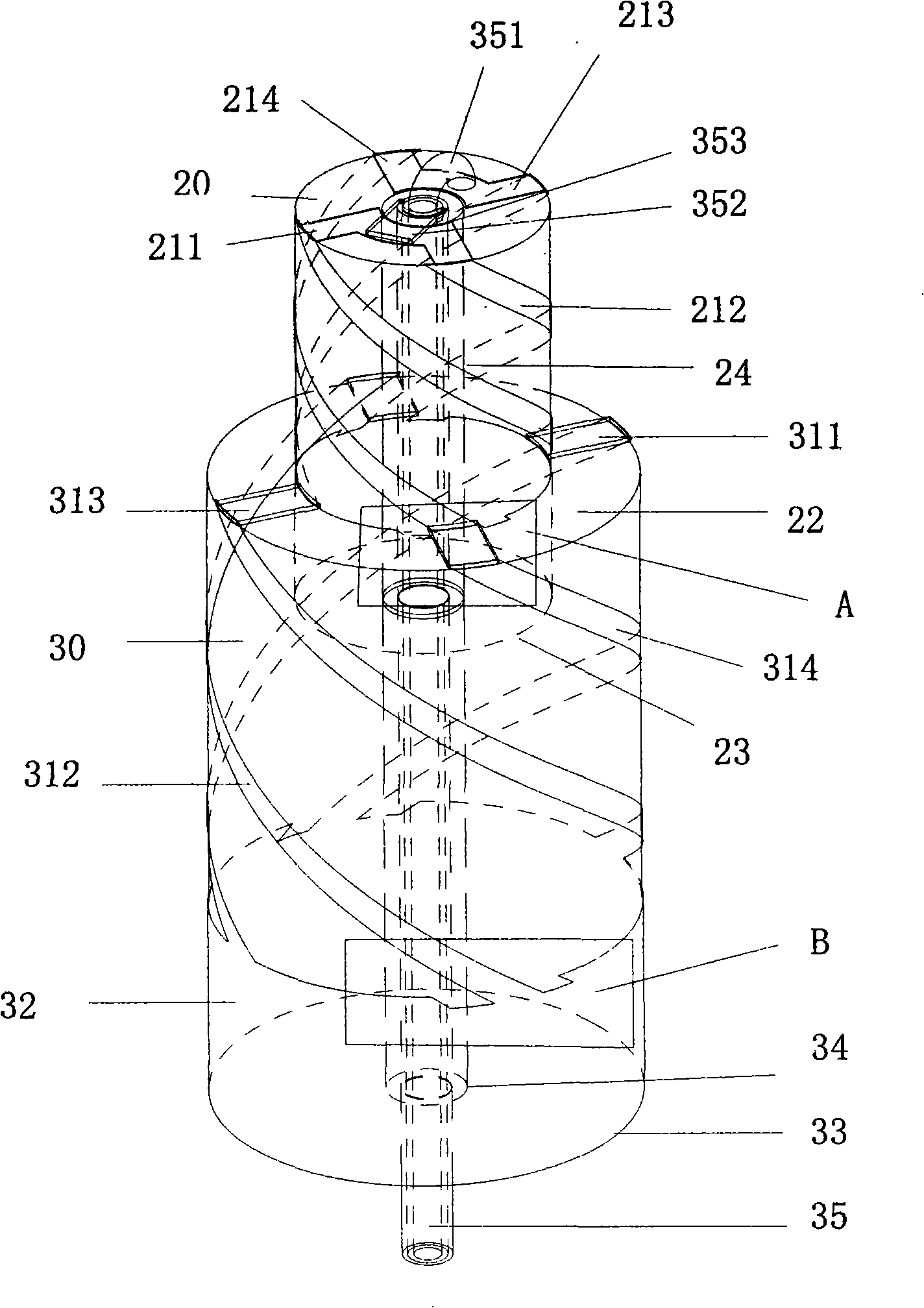

[0050] The specific structure of the antenna is as figure 2 As shown: the metal layer 22 on the outer surface of the bottom circumference of the columnar body 20 is completely inserted into the top of the columnar body 30, and the two are closely attached to form an integral structure.

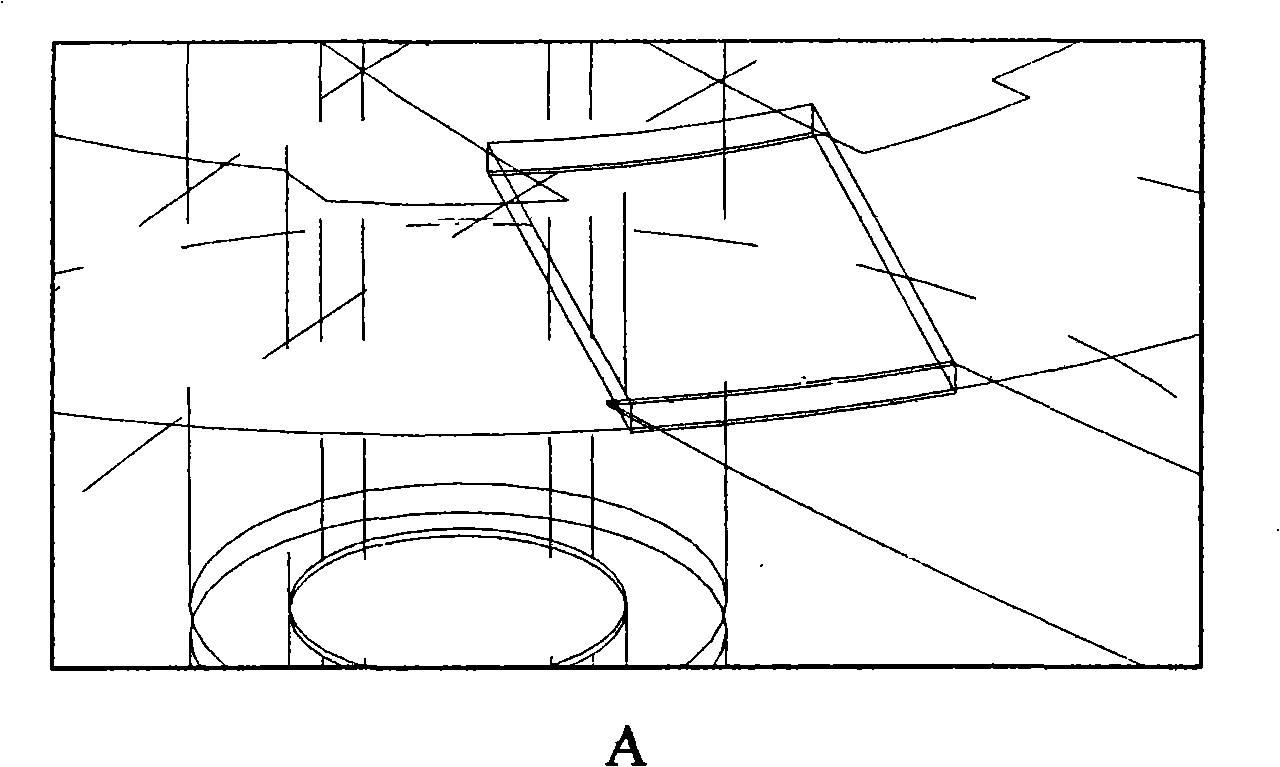

[0051] The radiating metal sheets 211, 212, 213, 214 extend in a helical path along the side of the columnar body 20, and they have the same pitch. In order to realize that the length of the radiating metal sheets 212 and 214 is about 0.05λ longer than the radiating metal sheets 211 and 213 1 , two small grooves (such as image 3 shown), where λ 1 Be the wavelength of the first operating frequency band of the antenna; similarly, the radiating metal sheets 311, 312, 313, 314 extend along the side of the columnar body 30 according to a helical path, and they have the same pitch, so that the length of the radiating metal sheets 312 and 314 is approximately 0.05λ longer than radiating metal she...

Embodiment 3

[0054] The specific structure of the antenna is as figure 1 Shown: the columnar body 20 is made of a dielectric material with a dielectric constant of 7.0, and the electrical length of the metal layer 22 is 0.31λ 1 ; The columnar body 30 is made of a dielectric material with a dielectric constant of 6.0, and the electrical length of the metal layer 32 is 0.27λ 2 The diameter ratio of the columnar body 30 to the columnar body 20 is 1.5, and the height ratio is 1.43. The metal layer 22 on the outer surface of the bottom circumference of the columnar body 20 is all inserted into the top of the columnar body 30, and the two are closely fitted to form an overall structure.

[0055] In order to realize the 90° phase difference between the radiating metal sheets 211, 212, 213, 214, the radiating metal sheets 211 and 213 extend in a spiral along the side of the columnar body 20 in a straight line, around the length of the columnar body 20 0.48λ 1 , while the radiating metal sheets 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com