Method for preparing glossy ganoderma spore oil

A technology of Ganoderma lucidum spore oil and Ganoderma lucidum spore powder, which is applied in food preparation, food forming, edible oil/fat and other directions, can solve the problems of extraction temperature, wide pressure, difficult to master process conditions, high-purity spore oil products, difficult industrialization, etc. problems, to achieve the effect of suitable pressure, short extraction time and mild operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

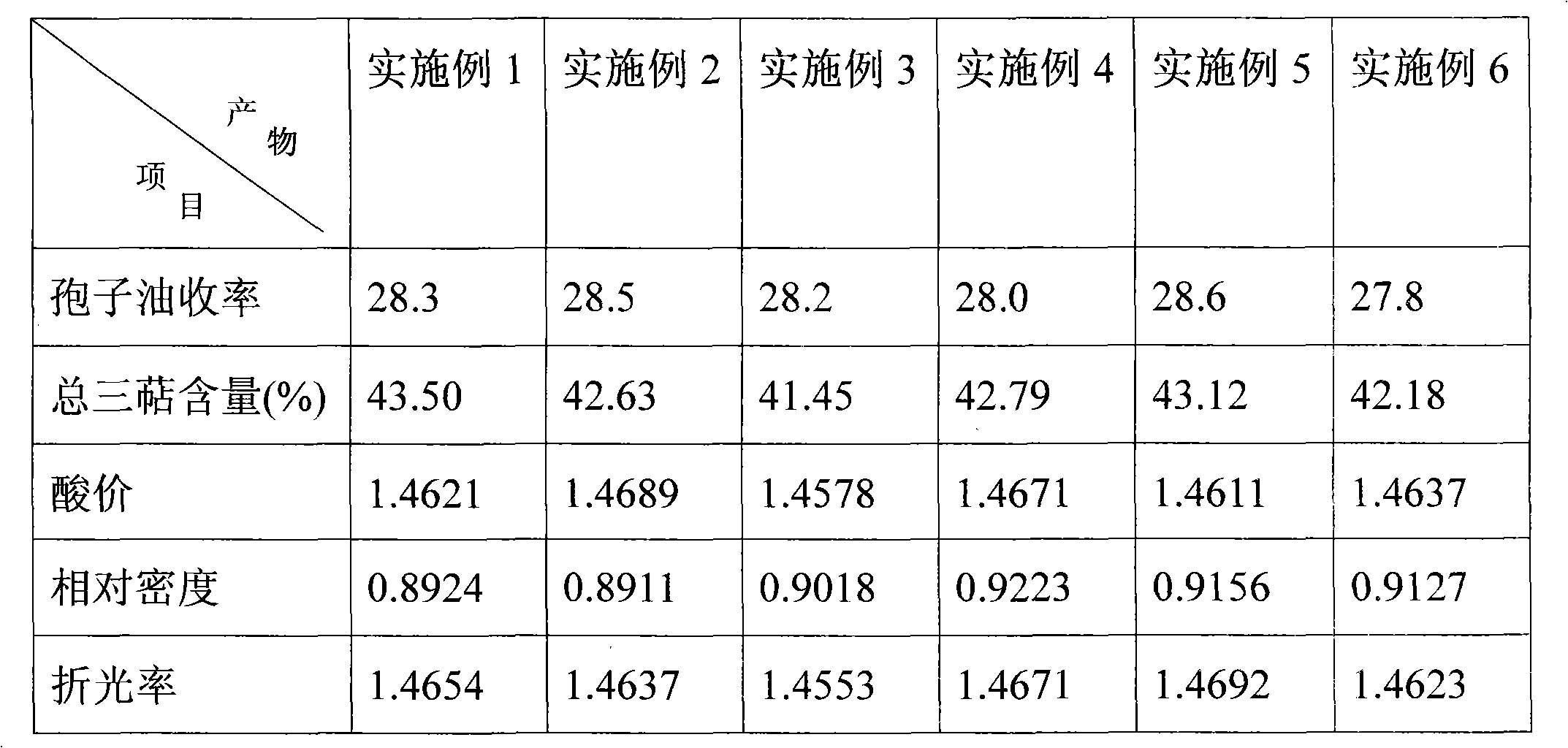

Examples

Embodiment 1

[0019] Get the ganoderma lucidum spore powder 1Kg of broken wall, make wetting agent with pure water, make soft material, extrude after making 20 mesh grains, dry 3 hours at 60 ℃, obtain the spore powder particle that water content is 2.8%. Placed in a 10-liter supercritical carbon dioxide extraction kettle, the carbon dioxide is pressurized by a high-pressure pump for circular extraction. The pressure of the extraction kettle is 35MPa, and the temperature is 42°C. The carbon dioxide flow rate is 25L / H, the primary separation pressure is 10MPa, and the temperature is 57°C. The secondary separation pressure is 5MPa and the temperature is 32°C. After continuous extraction for 2 hours, the resulting oil was collected in a separator. Stand at room temperature for 15 days, take the light yellow oily liquid with a special smell of spore powder in the upper layer, and filter it with an ultrafiltration membrane device with a filtration accuracy of 0.1 micron to obtain 0.283Kg of oil...

Embodiment 2

[0021] Get 1Kg of Ganoderma lucidum spore powder washed and broken, use pure water as wetting agent to make soft material, extrude to form 20 mesh grains, dry at 45°C for 2 hours to obtain spore powder particles with water content less than 3%. Placed in a 10-liter supercritical carbon dioxide extraction kettle, the carbon dioxide is pressurized by a high-pressure pump for circular extraction. The pressure of the extraction kettle is 34MPa, the temperature is 47°C, the flow rate of carbon dioxide is 29L / H, the primary separation pressure is 9MPa, and the temperature is 56°C. The secondary separation pressure is 4MPa and the temperature is 31°C. After continuous extraction for 1.5 hours, the resulting mixture was collected in a separator. Stand still at normal temperature for 20 days, take the light yellow oily liquid with the special smell of spore powder in the upper layer, filter it with ultrafiltration membrane equipment, and the filtration accuracy is 0.1 micron to obtain...

Embodiment 3

[0023] Get the ganoderma lucidum spore powder 1Kg of broken wall, make wetting agent with pure water, make soft material, extrude after making 20 mesh grains, dry 2 hours at 45 ℃, obtain the spore powder particle that water content is 2.9%. Placed in a 10-liter supercritical carbon dioxide extraction kettle, the carbon dioxide is pressurized by a high-pressure pump for circular extraction. The pressure of the extraction kettle is 33MPa, the temperature is 44°C, the flow rate of carbon dioxide is 30L / H, the primary separation pressure is 8MPa, and the temperature is 57°C. The secondary separation pressure is 3MPa and the temperature is 32°C. After continuous extraction for 4 hours, the resulting mixture was collected in a separator. Stand at room temperature for 10 days, take the light yellow oily liquid with a special smell of spore powder in the upper layer, and filter it with an ultrafiltration membrane device with a filtration accuracy of 0.1 micron to obtain 0.282Kg of an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com