Solid beverage and preparation method there of

A solid beverage and the technology of the production method are applied in the field of sports health nutrition beverages to achieve the effects of enhancing endurance, stimulating the human immune system, and protecting joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

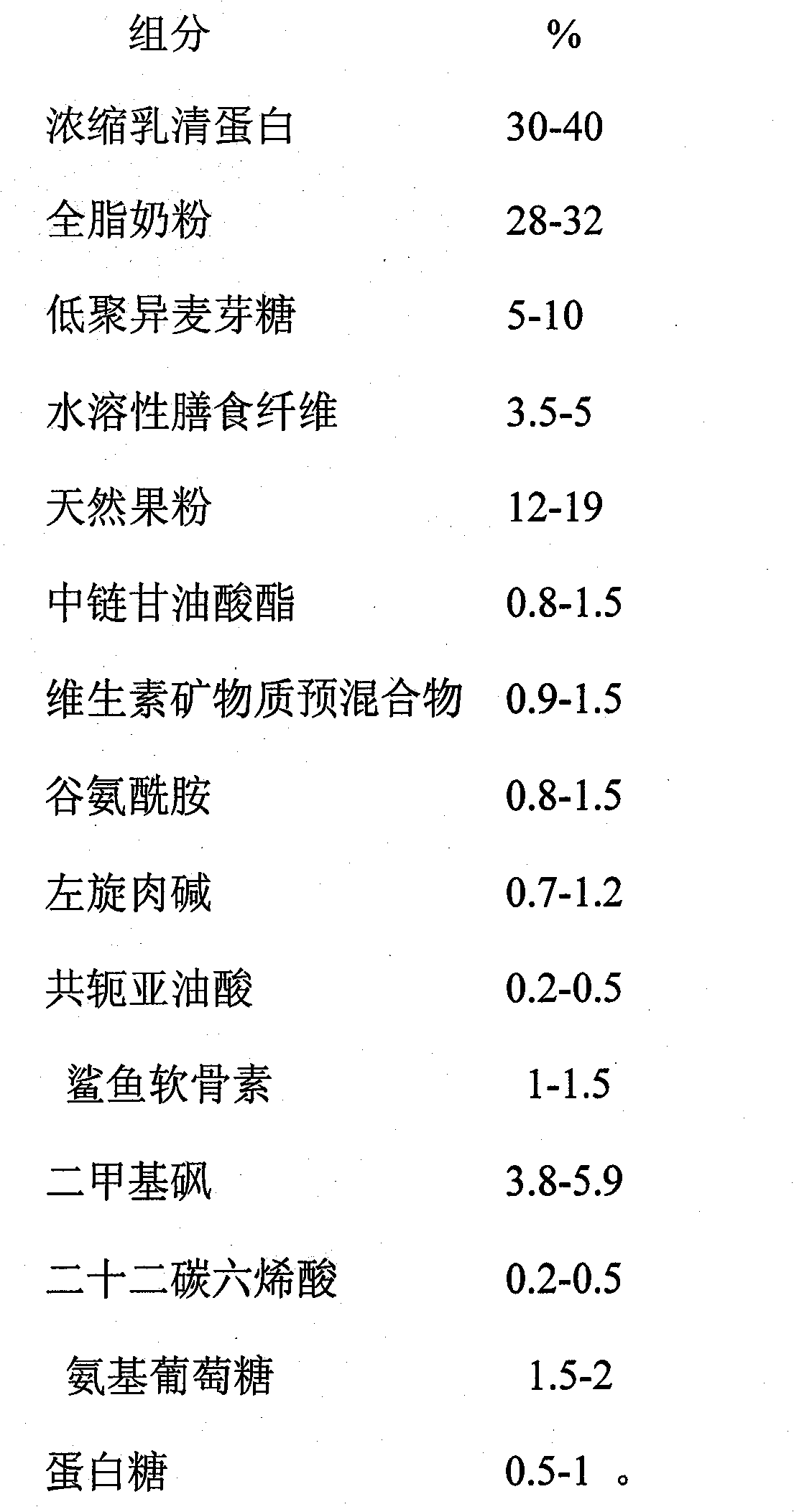

Method used

Image

Examples

Embodiment 1

[0058] First prepare the raw materials according to the following weight (gram) unit ratio:

[0059] Component grams

[0060] Whey Protein Concentrate 200

[0061]Whole milk powder 180

[0062] Isomaltooligosaccharide 48

[0063] Soluble Dietary Fiber 24

[0064] Natural Fruit Powder 72

[0065] Medium Chain Glycerides (MCT) 6

[0066] Vitamin Mineral Premix 6

[0067] Glutamine 6

[0068] L-Carnitine 6

[0069] Conjugated Linoleic Acid (CLA) 1.5

[0070] Shark Chondroitin 6

[0071] Dimethylsulfone (MSM) 27

[0072] Docosahexaenoic acid (DHA) 1.5

[0073] Glucosamine 10

[0074] Meringue 6

[0075] Production Method:

[0076] Put the above prepared raw materials into the drying mixer evenly, the control time is 25-40 minutes, and the temperature is set at 75-80°C, so that the materials are fully mixed and the water is removed at the same time. The water content is controlled at 3-5%. The transmission pipeline enters the colloid mill pulverizer, and the set mesh...

Embodiment 2

[0078] First prepare the raw materials according to the following weight (gram) unit ratio:

[0079] Component grams

[0080] Whey Protein Concentrate 180

[0081] Whole milk powder 180

[0082] Isomaltooligosaccharide 36

[0083] Water Soluble Dietary Fiber 48

[0084] Natural Fruit Powder 80

[0085] Medium Chain Glycerides (MCT) 7.2

[0086] Vitamin Mineral Premix 6

[0087] Glutamine 6

[0088] L-Carnitine 5

[0089] Conjugated Linoleic Acid (CLA) 2

[0090] Shark Chondroitin 9

[0091] Dimethylsulfone (MSM) 24

[0092] Docosahexaenoic acid (DHA) 1.8

[0093] Glucosamine 9

[0094] Meringue 6

[0095] Production Method:

[0096] Put the above prepared raw materials into the drying mixer evenly, the control time is 25-40 minutes, and the temperature is set at 75-80°C, so that the materials are fully mixed and the water is removed at the same time. The water content is controlled at 3-5%. The transmission pipeline enters the colloid mill pulverizer, and the se...

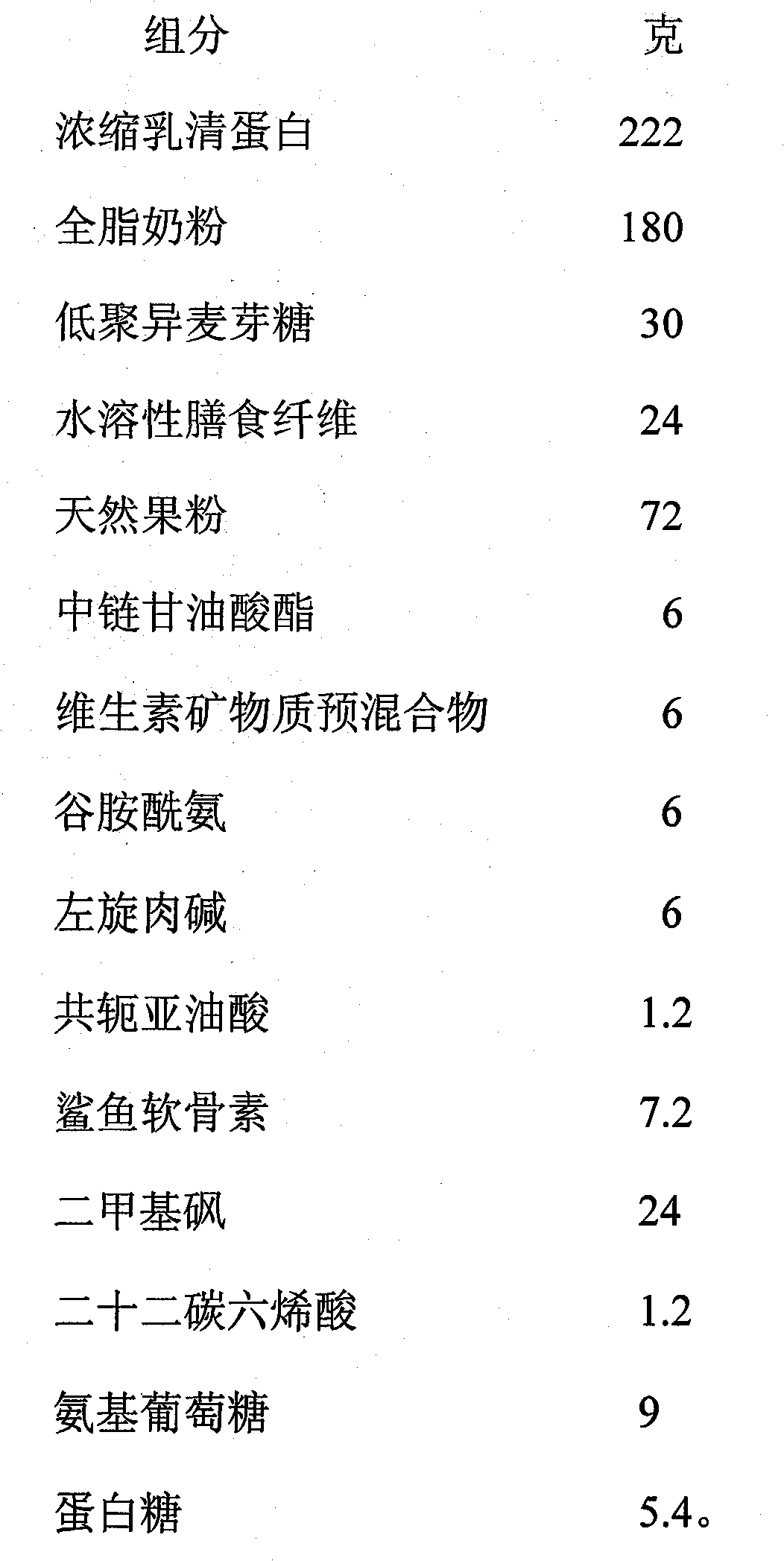

Embodiment 3

[0098] First prepare the raw materials according to the following weight (gram) unit ratio:

[0099] Component grams

[0100] Whey Protein Concentrate 222

[0101] Whole milk powder 180

[0102] Isomaltooligosaccharide 30

[0103] Soluble Dietary Fiber 24

[0104] Natural Fruit Powder 72

[0105] Medium Chain Glycerides (MCT) 6

[0106] Vitamin Mineral Premix 6

[0107] Glutamine 6

[0108] L-Carnitine 6

[0109] Conjugated Linoleic Acid (CLA) 1.2

[0110] Shark Chondroitin 7.2

[0111] Dimethylsulfone (MSM) 24

[0112] Docosahexaenoic acid (DHA) 1.2

[0113] Glucosamine 9

[0115] Production Method:

[0116] Put the above prepared raw materials into the drying mixer evenly, the control time is 25-40 minutes, and the temperature is set at 75-80°C, so that the materials are fully mixed and the water is removed at the same time. The water content is controlled at 3-5%. The transmission pipeline enters the colloid mill pulverizer, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com