Production manufacturing method of carbon powder

A manufacturing method and carbon technology, applied in the field of carbon powder M production and manufacturing, can solve the problems of reducing material capacity, complex processing technology and high processing cost, and achieve the effects of improving material specific capacity, simple process method, mature and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 3

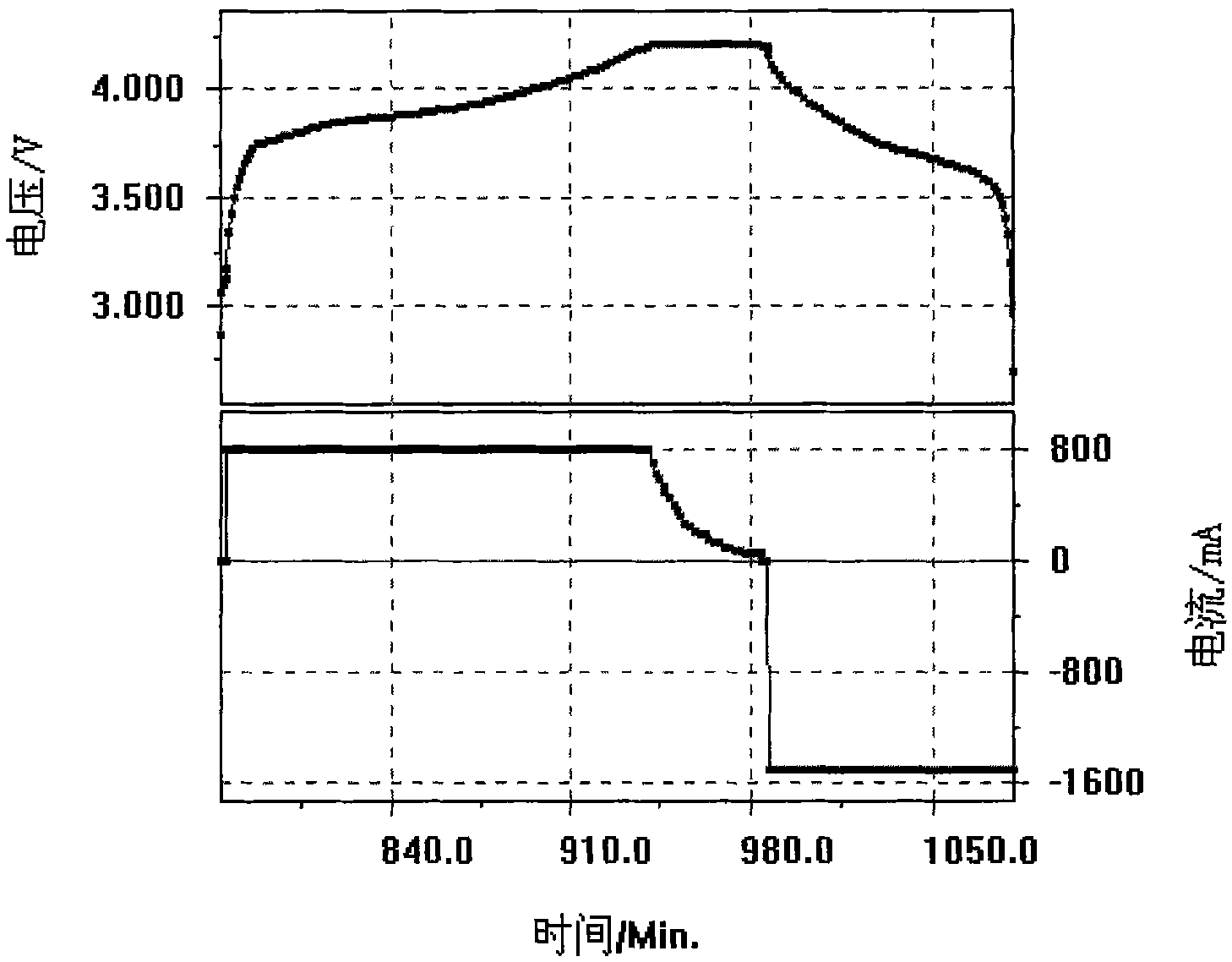

[0087] The prolongation of time finds that the coke conversion carbon process meets the requirements more than example three;

[0088] (6) Three kinds of materials through the above processes are crushed with a crusher, and classified processing is carried out;

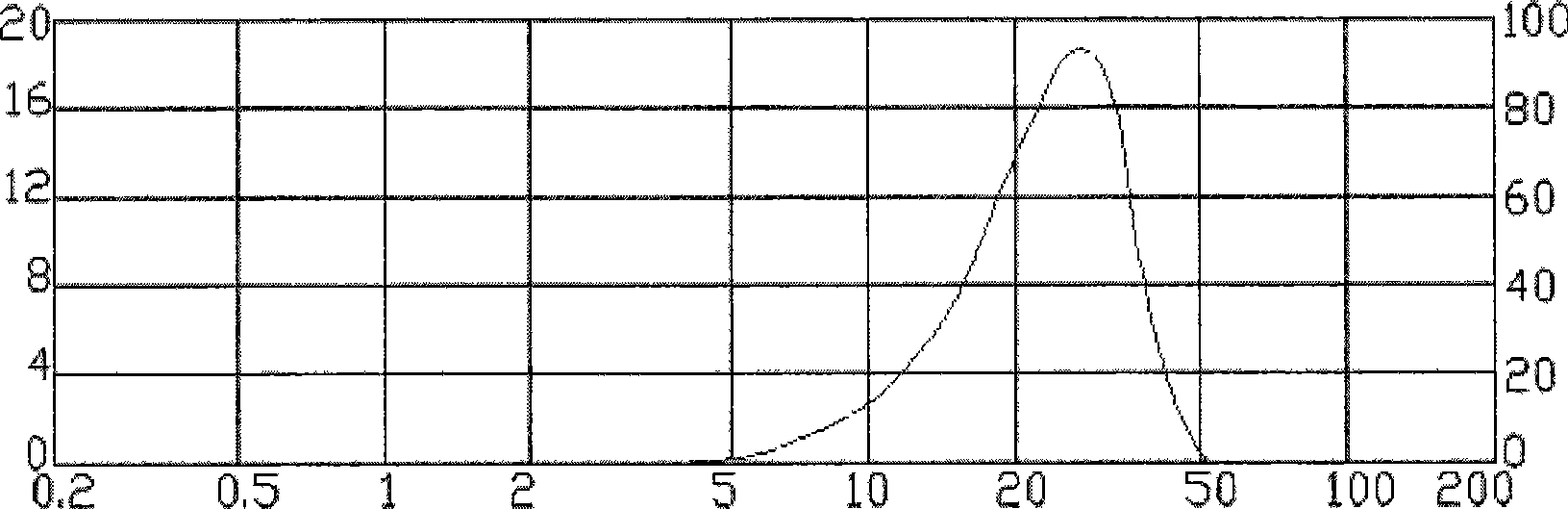

[0089] (7) Then use the airflow to grind coarse, medium and fine processing step by step; in the grinding process, it is found that with the gradual increase of the graphitization temperature, the closer the carbon powder is to the ideal index;

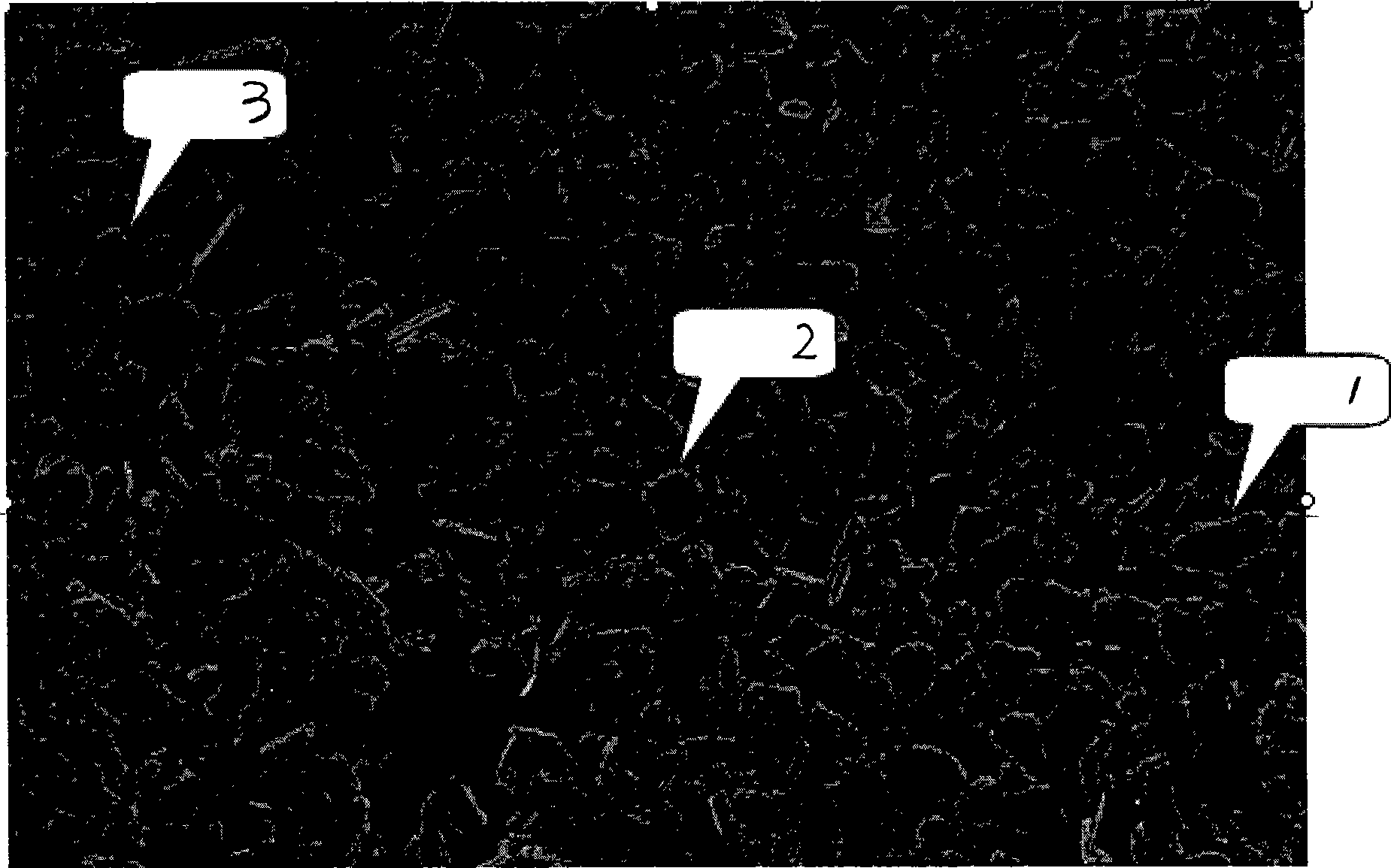

[0090] (8) Three kinds of materials are respectively carried out particle size shaping to be layered, sub-ellipse, sub-circle;

[0091] (9) Mix the layered, oval-like and round-like materials in a ratio of 40:30:30 and stir them fully;

[0092] (10) Carry out the high temperature carbonization treatment of at least 2000°C for 1 day to the carbon powder obtained in process 9; the surface of the carbon powder screened after carbonization is more ideal than that in Example 3; c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com