Internal combustion engine turbocharging system

A turbocharging system and internal combustion engine technology, applied in the direction of internal combustion piston engines, combustion engines, gas turbine devices, etc., can solve the problems of harsh working conditions, high cost, low boost pressure, etc., to achieve accelerated response, low cooling requirements, The effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

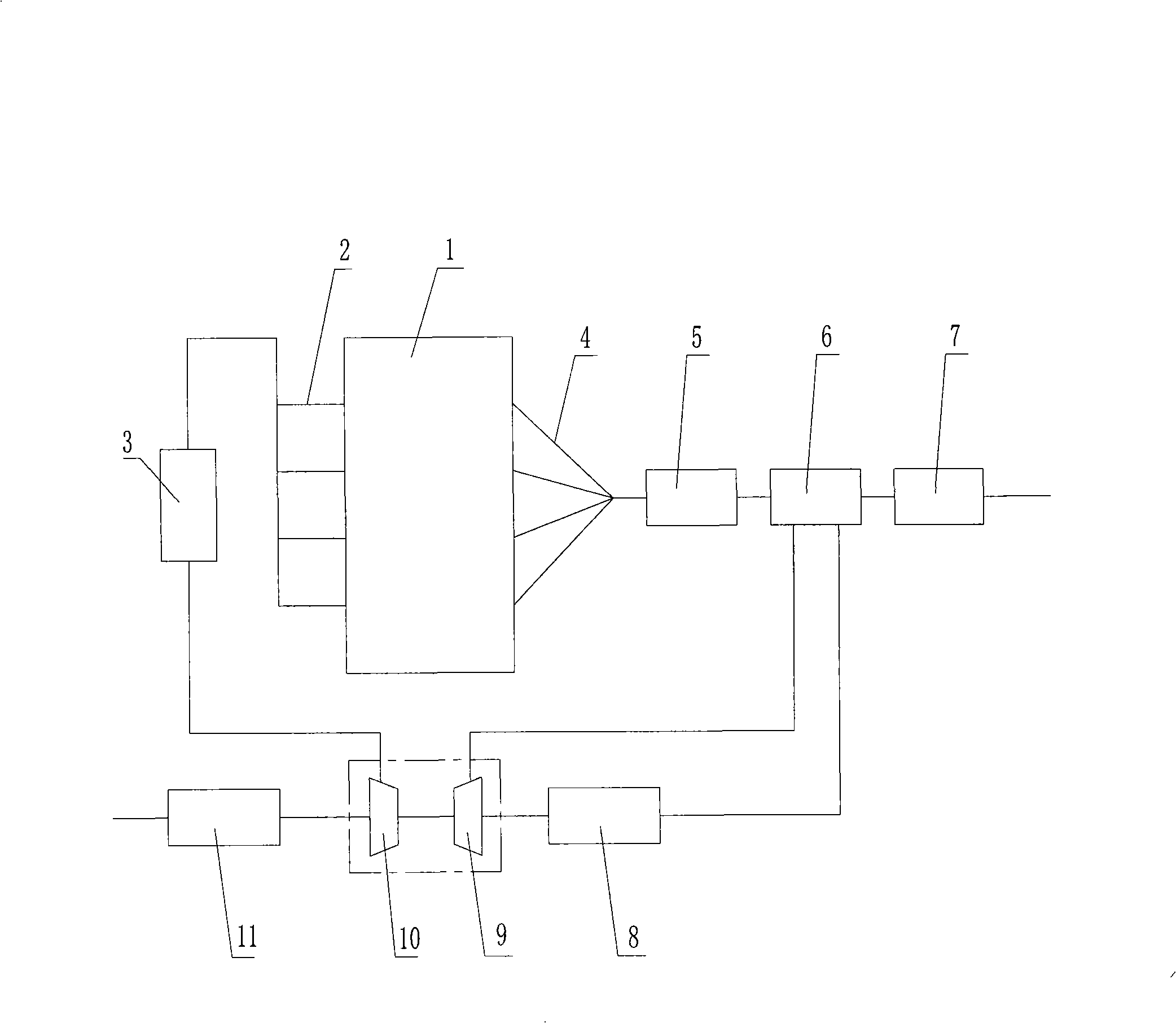

[0012] Example 1 as figure 1 As shown, it is a supercharged and intercooled internal combustion engine, including an internal combustion engine 1. The exhaust gas discharged from the internal combustion engine 1 enters the catalytic converter 5 after being collected through the exhaust manifold 4, and then passes through the evaporator 6, where the exhaust gas and the water in the evaporator are heated. Exchange, the temperature of the exhaust gas is greatly reduced, then enters the muffler 7, and finally is discharged into the atmosphere. The evaporator 6 fully absorbs the heat of the exhaust gas to generate high-temperature and high-pressure water vapor. The water vapor enters the turbine 9 of the supercharger through the transmission pipeline, drives the turbine to rotate at high speed, and drives the impeller of the coaxial compressor 10 to rotate. The water vapor passing through the turbine 9 enters the condenser 8 through the circulation pipeline, and is cooled in the co...

Embodiment 2

[0013] Embodiment 2 A supercharged internal combustion engine, including internal combustion engine 1, is characterized in that the present invention may not use an intercooler before the intake manifold, and the rest are the same as Embodiment 1.

Embodiment 3

[0014] Embodiment 3 A supercharged internal combustion engine, including the internal combustion engine 1, is characterized in that the supercharger can use various variable mechanisms to control the supercharging pressure, or use a simpler structure to change the turbocharger. Pressure. All the other are with embodiment 1 or 2.

[0015] The present invention is not limited to the structure of the above embodiment, it can also be used together with the exhaust gas turbocharger to form a compound supercharging system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com