Micro hollow silicon needle and preparation method thereof

A hollow silicon, micro-technology, applied in the field of medical and semiconductor micro-processing, can solve the problems of micro-needle structure difficult to penetrate the skin, leaking transdermal drug delivery, easy to break, etc., to achieve simple manufacturing process, strong structure, short production cycle short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

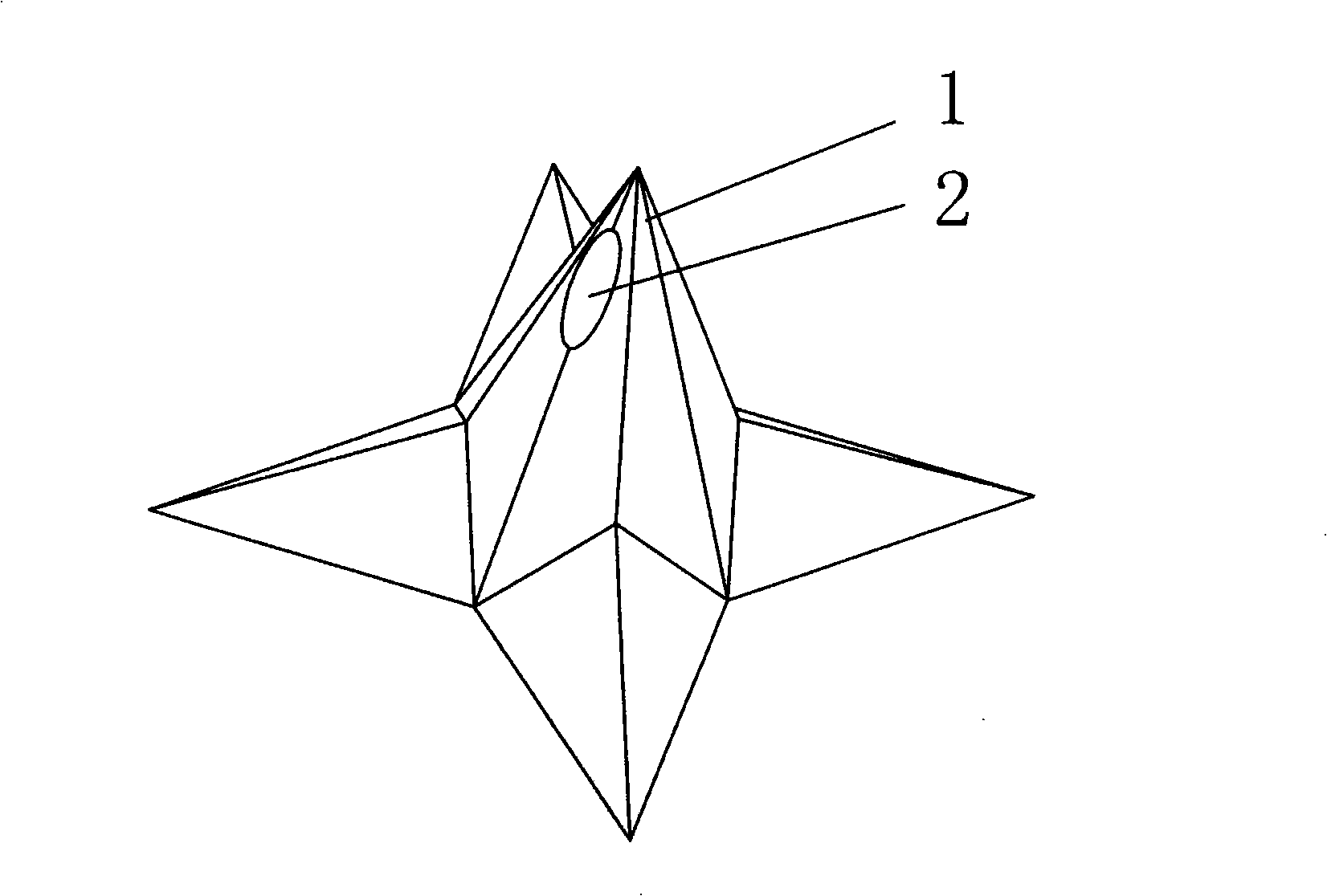

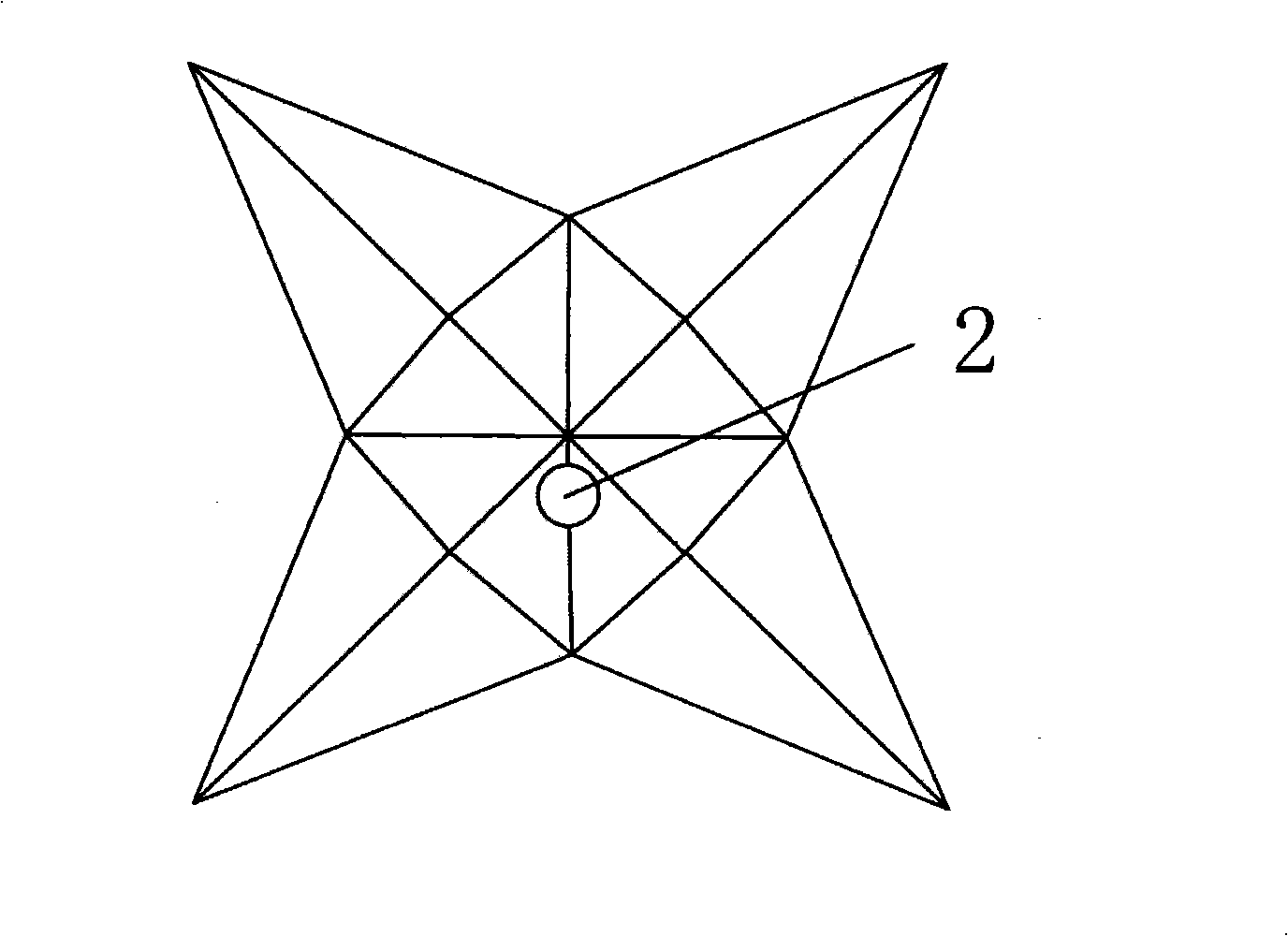

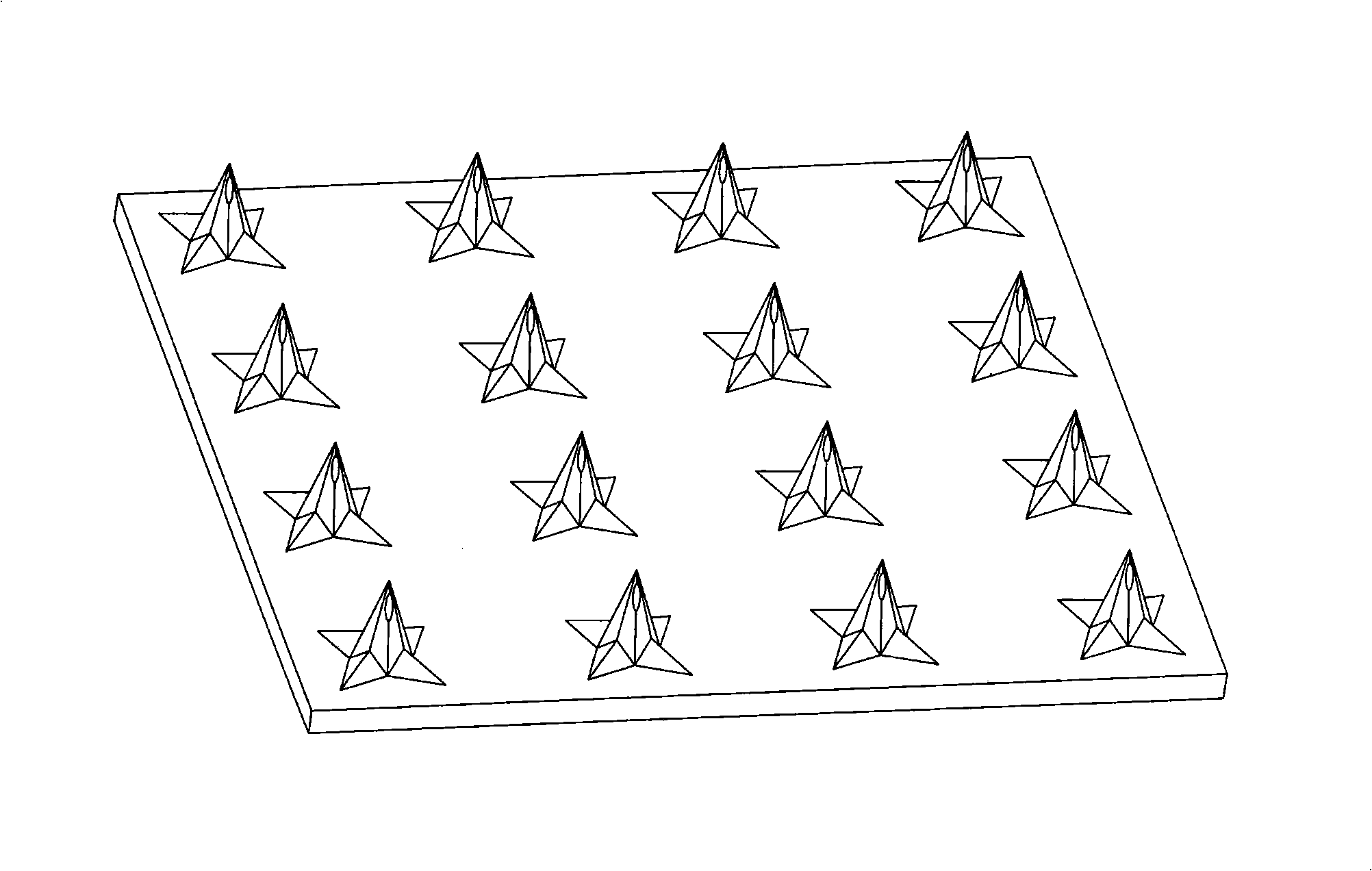

[0037] Such as Figure 1a ~ Figure 3b Shown, the embodiment of the present invention provides a kind of micro hollow silicon needle, the needle head of described micro hollow silicon needle is pyramid-shaped, can be octagonal pyramid (referring to Figure 1a with Figure 1b ) or quadrangular pyramid (refer to Figure 3a with Figure 3b ). There are through holes perpendicular to the silicon wafer substrate on the needle tip or the side wall of the microneedle. The diameter of the through hole at different positions may vary, and there may be short branch holes. Whether there are branch holes and the existence of branches The specific shape and quantity of the holes dep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com