High strength coating cloth for tarpaulin of goods train and preparation thereof

A railway freight car, high-strength technology, used in railway car body parts, non-woven fabrics, textiles and papermaking, etc., can solve the problems of short service life, rough surface, substandard tensile force and elongation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: This embodiment includes a high-strength low-shrinkage polyester filament base fabric and a PVC coating agent coated on the base fabric.

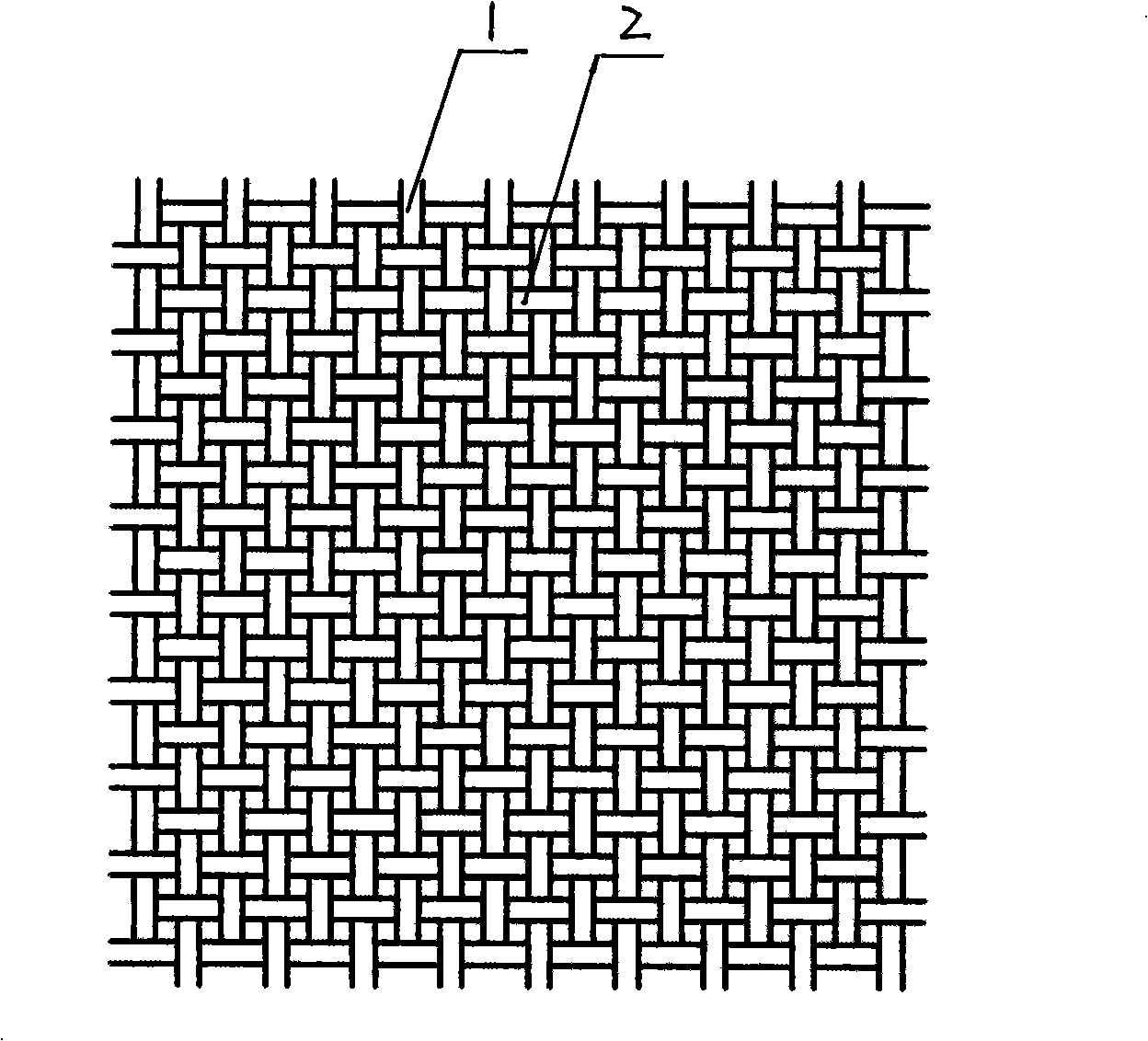

[0030] (1) The production of base cloth: such as figure 1 As shown, 800D-1300D high-strength and low-shrinkage polyester filaments are used as warp yarn 1 and weft yarn 2, and are woven into plain woven fabrics with imported extra-wide shuttleless looms.

[0031] (2) Production of PVC coating agent: PVC coating agent is composed of base material and fabric. The base material is made by mixing the following raw materials, calculated by weight ratio: PVC paste resin (P-450) 100, dioctyl phthalate (DOP) 50, dioctyl sebacate (DOS) 5, Dioctyl adipate (DOA) 5, liquid barium zinc stabilizer 2, antimony trioxide 10, zinc borate 5, aluminum hydroxide 5, calcium carbonate 10, antioxidant 1010 0.2, chlorothalonil 0.5, titanium blue 19.9, fast red 0.1. The fabric is made by mixing the following raw materials, calculated by weigh...

Embodiment 2

[0035] Embodiment 2: This embodiment includes a high-strength low-shrinkage polyester filament base fabric and a PVC coating agent coated on the base fabric.

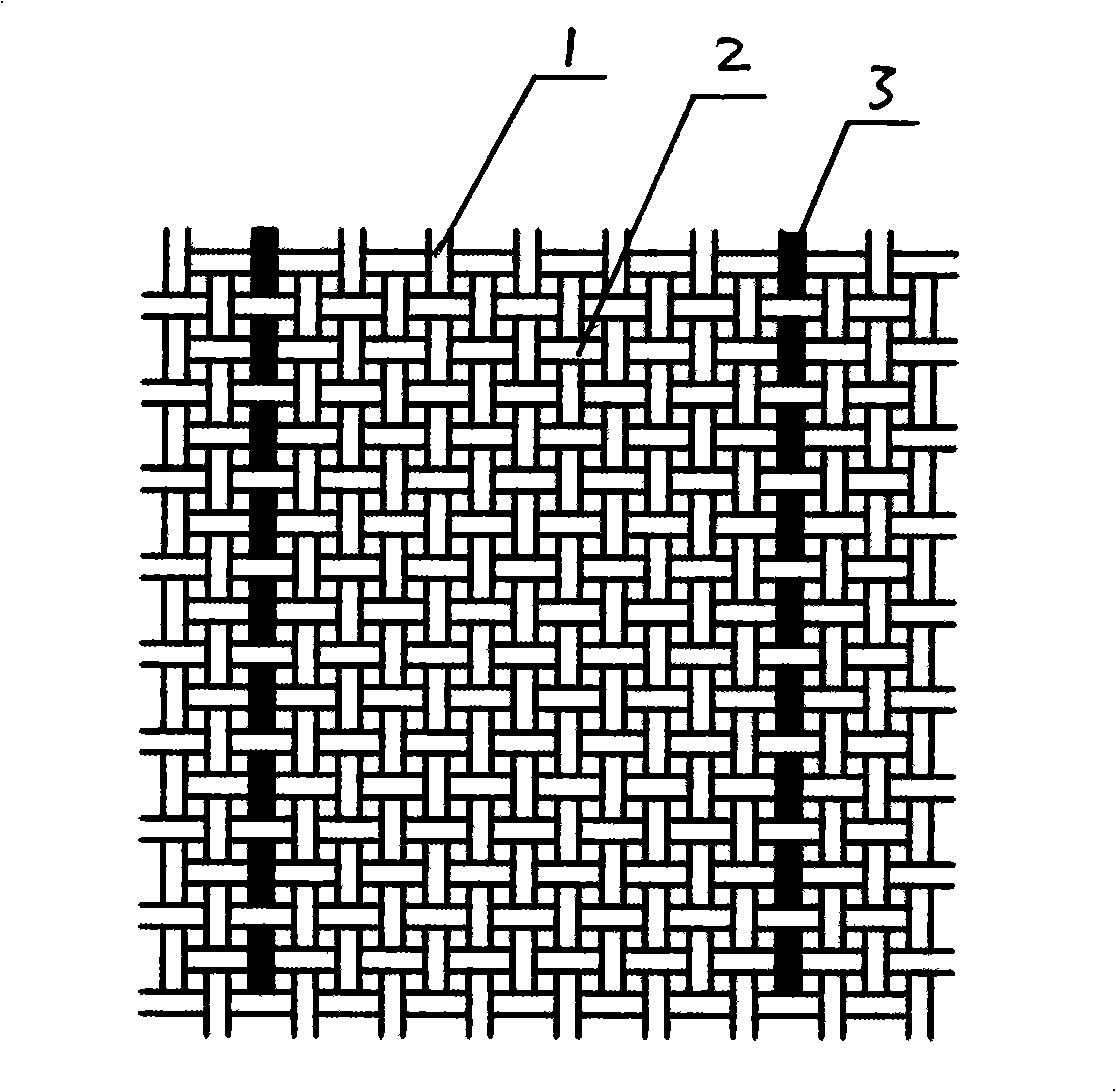

[0036] (1) The production of base cloth: such as figure 2 As shown, 1000D high-strength and low-shrinkage polyester filaments are used as warp yarn 1 and weft yarn 2, and are woven into plain weave fabrics with imported extra-wide shuttleless looms. A reinforcing rib 3 is stacked, and the reinforcing rib 3 is made of 1000D high-strength and low-shrinkage polyester filament.

[0037] (2) Production of PVC coating agent: PVC coating agent is composed of base material and fabric. The base material is made by mixing the following raw materials, calculated by weight ratio: PVC paste resin (M-31) 100, dioctyl phthalate (DOP) 40, dioctyl sebacate (DOS) 8, Dioctyl adipate (DOA) 8, liquid calcium zinc stabilizer 1.5, liquid barium zinc stabilizer 1.5, antimony trioxide 15, zinc borate 4, aluminum hydroxide 8, calcium carbonate ...

Embodiment 3

[0041] Embodiment 3: This embodiment includes a high-strength low-shrinkage polyester filament base fabric and a PVC coating agent coated on the base fabric.

[0042] (1) The production of base cloth: such as figure 2 As shown, 1000D high-strength and low-shrinkage polyester filaments are used as warp yarn 1 and 1300D high-strength low-shrinkage polyester filaments are used as weft yarn 2, and plain weave fabrics are woven into plain weave fabrics with imported extra-wide shuttleless looms. A reinforcing rib 3 is superimposed on the warp yarn 1 every 3 cm, and the reinforcing rib 3 is made of 1000D high-strength and low-shrinkage polyester filament.

[0043] (2) Production of PVC coating agent: (2) Production of PVC coating agent: PVC coating agent is composed of base material and fabric. The base material is made by mixing the following raw materials, calculated by weight ratio: PVC paste resin (P-440) 100, dioctyl phthalate (DOP) 35, dioctyl sebacate (DOS) 13, Dioctyl adi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com