Engine oxygen-increasing pressure regulating energy-saving device

An energy-saving device and engine technology, which is applied to engine components, machines/engines, charging systems, etc., can solve problems such as the unsatisfactory effect of self-adaptive pressure regulation and oxygen increase, and achieve improved self-adaptive effect, accurate adjustment, and improved combustion. efficacy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

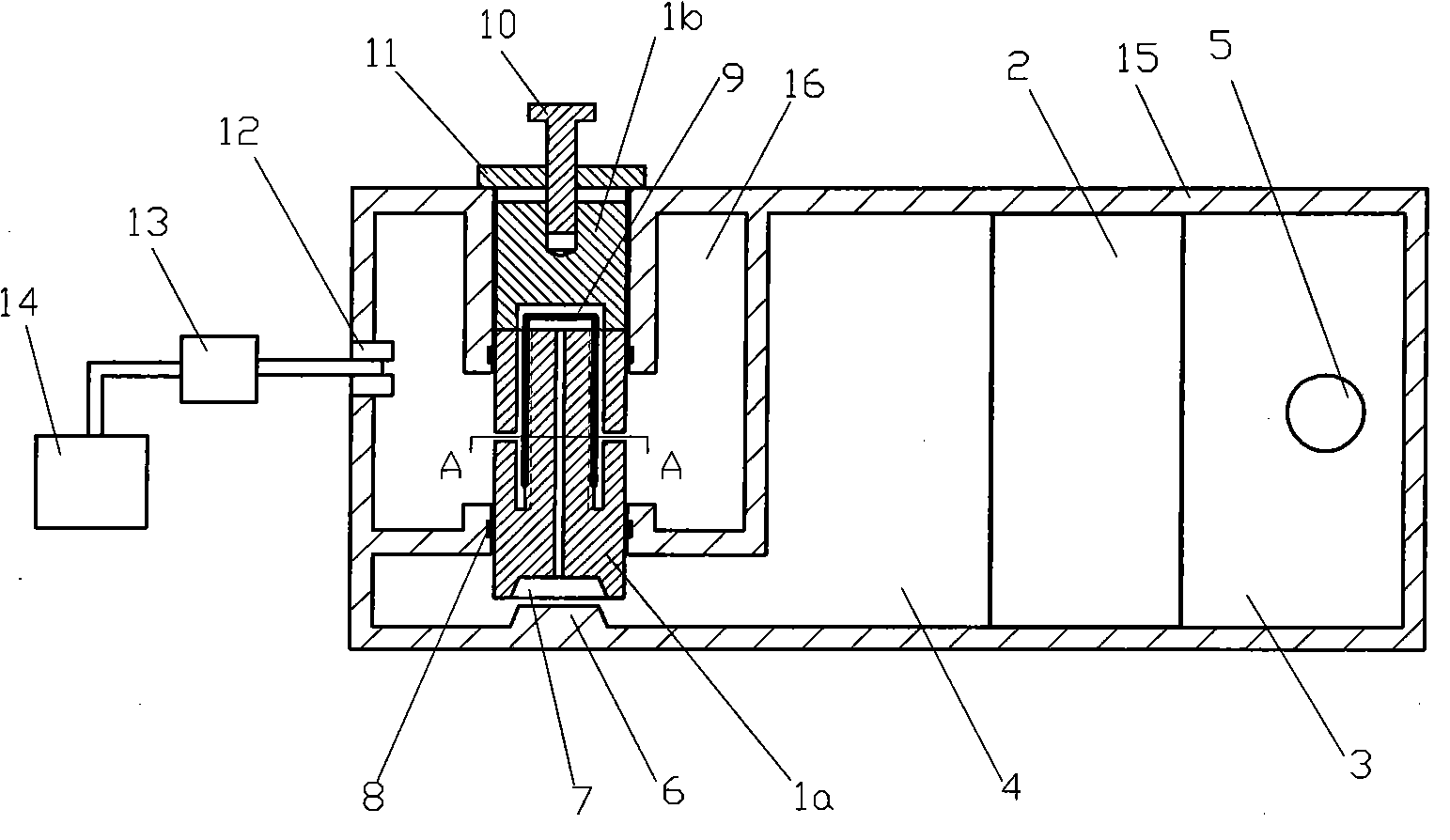

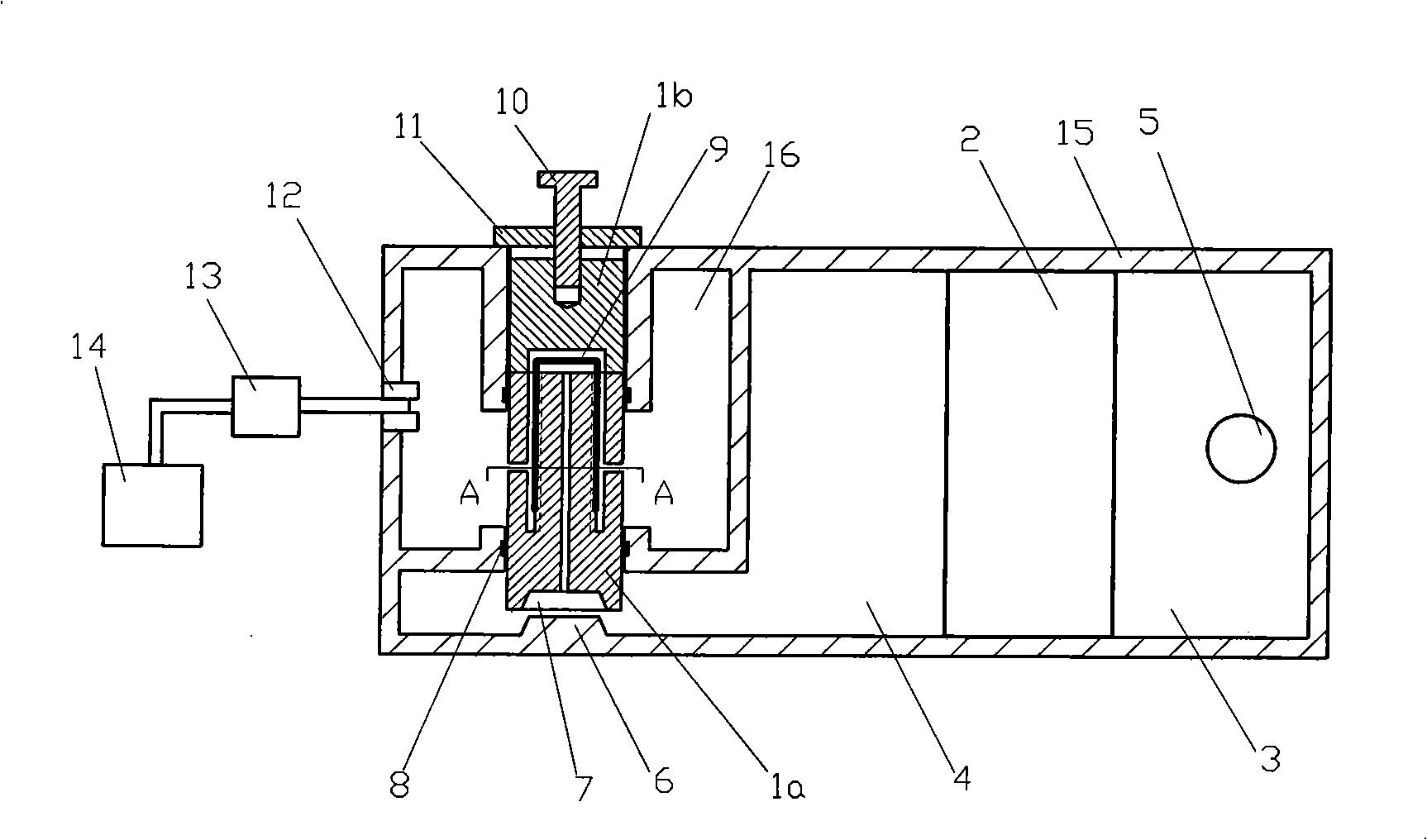

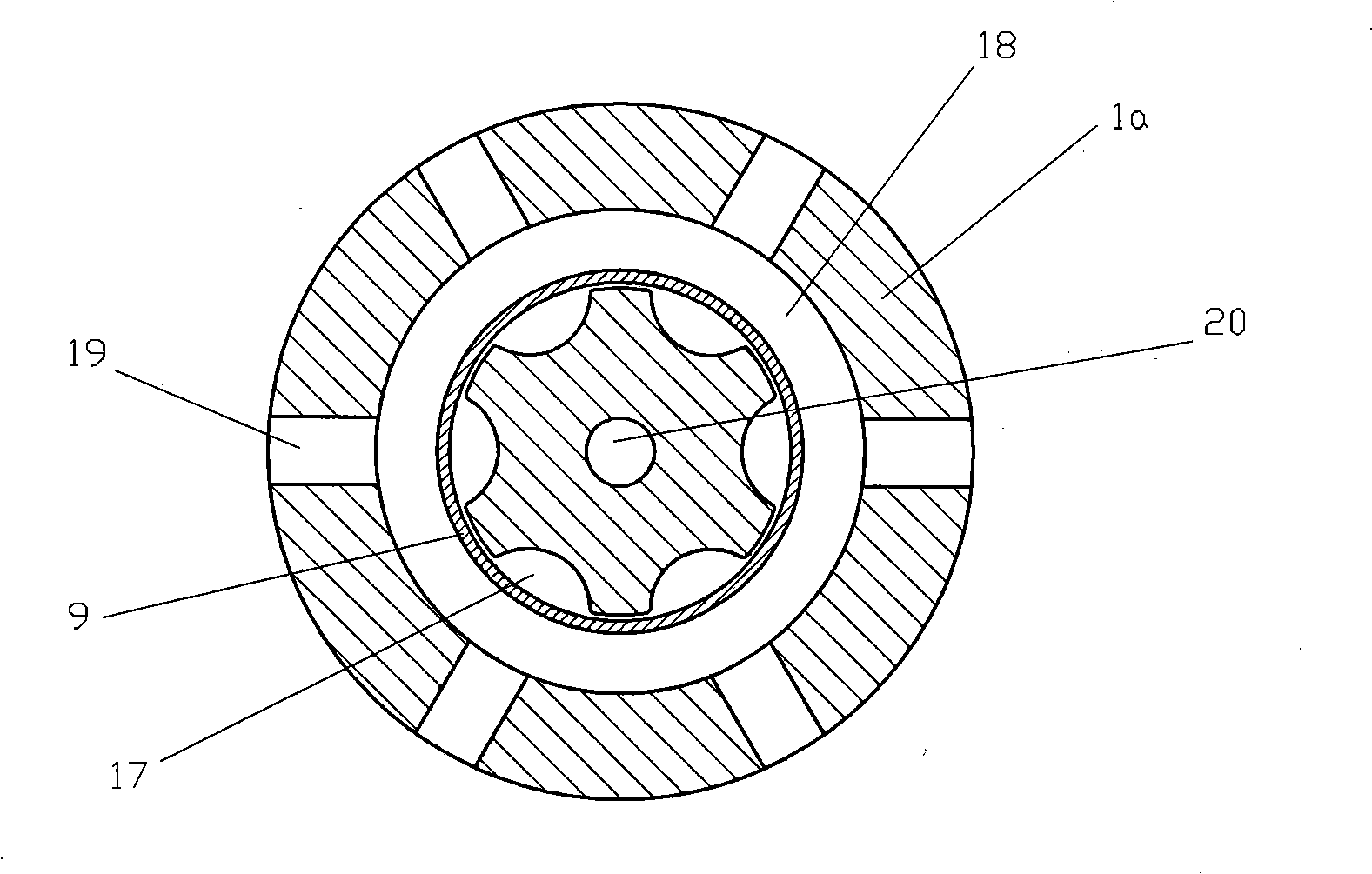

[0022] As shown in Figures 1 and 2, the engine oxygen-increasing and pressure-regulating energy-saving device of the present invention includes a box body 15, a gas filter device 2, and a gas flow regulating valve during implementation. The valve body of the gas flow regulating valve includes a valve seat 1b and a valve body. Head 1a. The gas filtering device 2 divides the inner cavity of the box body 15 into a pre-filter chamber 3 and a post-filter chamber 4, and a pressure regulating chamber 16 is set in the post-filter chamber 4, and the pre-filter chamber 3 is provided with The main air inlet 5 is provided with the main air outlet on the pressure regulating chamber, and the air outlet pipe card valve 12 is arranged at the main air outlet. The gas filtering device 2 can be made of layered macromolecular material, such as polyacrylonitrile ultrafiltration membrane, or a nitrogen filter. This embodiment directly adopts a nitrogen filter. It is arranged in the pre-filter cham...

Embodiment 2

[0025] The implementation of this example is basically the same as that of Example 1, except that the valve seat 1b and valve head 1a are made of copper or aluminum, and the cup-shaped thin-walled container is made of steel. Or a permanent magnet is set on the casing 15 to offset the gravity of the steel cup 9 and the frictional force between the steel cup 9 and the valve head 1a, so that the adaptive pressure regulation and oxygen increase effect is better; the gas filter 2 is arranged at intervals Several layers of polymer material filter layers, among which, the filter layer near the pre-filtration chamber 3 is made of polyacrylonitrile ultrafiltration membrane with a molecular cutoff of more than 5000, and the polyacrylonitrile ultrafiltration membrane can filter and remove part of nitrogen , increase the content of oxygen in the gas in the filtered chamber 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com