Acetaminopher DC90 fine particle and preparation method thereof

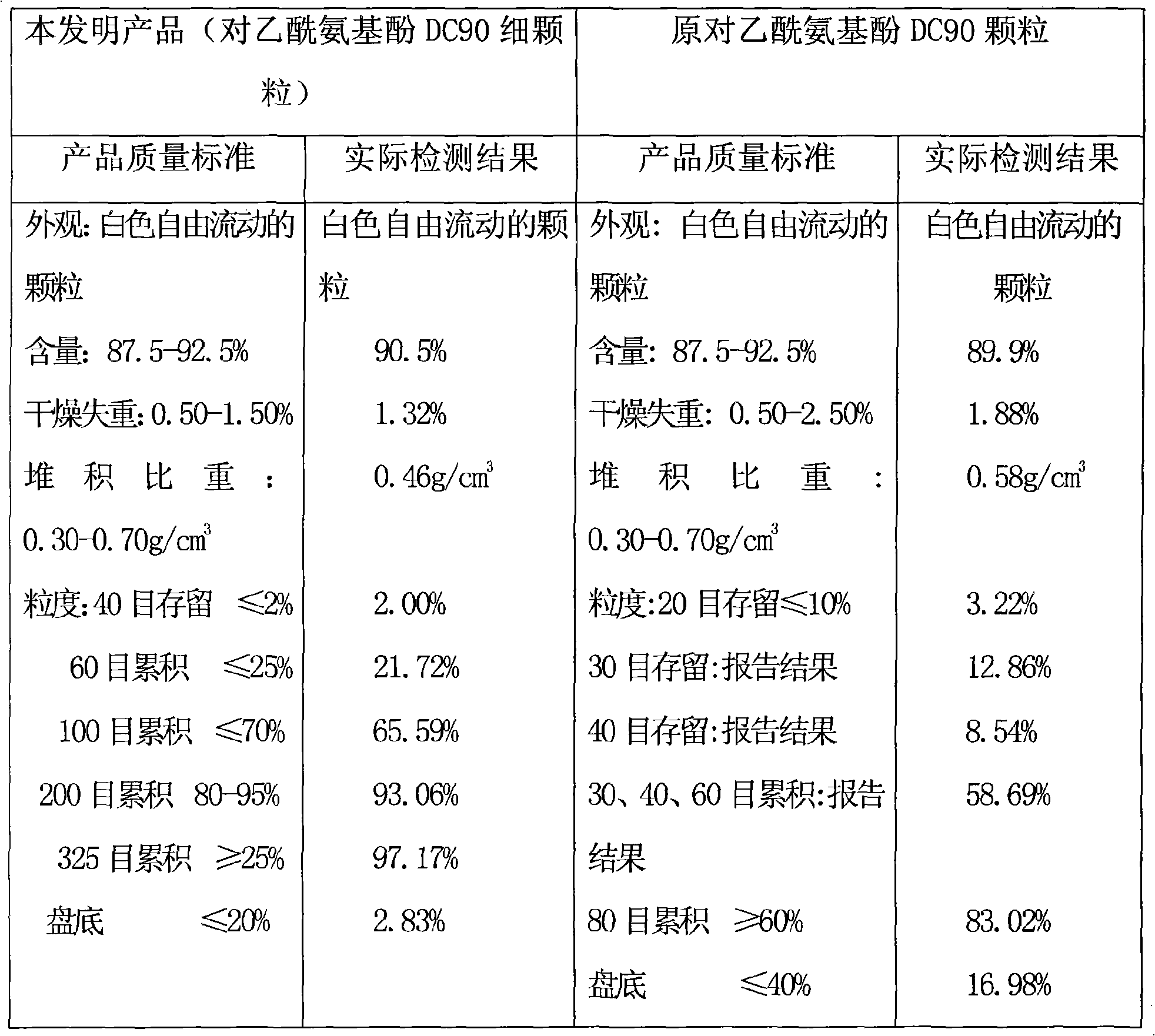

A technology of acetaminophen and fine particles, which is applied in the direction of pharmaceutical formulations, medical preparations containing active ingredients, and drug combinations, etc. It can solve the problems of uneven content of active ingredients, difficulty in mixing uniformly, and large accumulation ratio to achieve flow Good resistance, good compressibility, and small bulk specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] Embodiment: material proportioning:

[0037] Acetaminophen 310kg;

[0038] Corn starch 12.05kg;

[0039] Pregelatinized starch 12.05kg;

[0040] Povidone 6.90kg;

[0041] Crospovidone 1.72kg;

[0042] Stearic acid 1.72kg.

[0043] Preparation method: the specific process steps are as follows:

[0044] a) Ingredients: 310kg of acetaminophen and 12.05kg of cornstarch are packed into a batching tank and mixed evenly;

[0045] b) Feed material: Turn on the induced draft fan, set the inlet air temperature to 55°C and the air volume to 10000m 3 / h, spray pressure 2.0bar, suck the material from the batching tank into the material tank of the granulator;

[0046] c) Fluidized mixing: when the air inlet temperature is 55°C, the air volume is 1000m 3 / h, under the condition of spray pressure 2.0bar, fluidized and mixed for 5 minutes, stand-by;

[0047] d) Slurry preparation: add 12.05Kg of pregelatinized starch and 6.90Kg of povidone in sequence into the slurry tank of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com