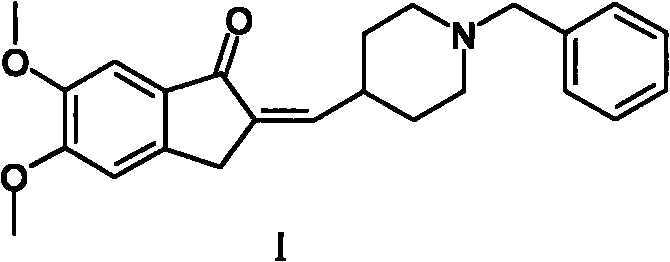

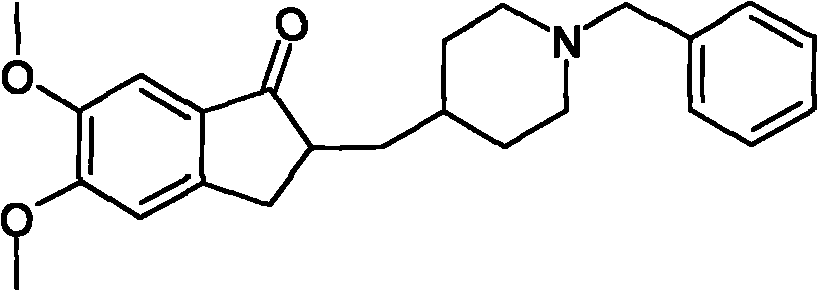

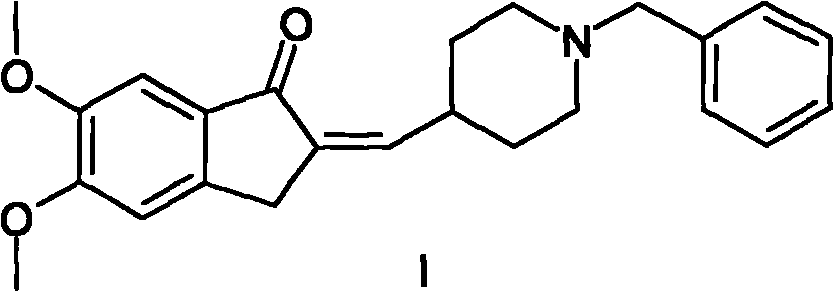

Fine purification method for key intermediate of Donepezil Hydrochloride

A technology of donepezil hydrochloride and a purification method, applied in directions such as organic chemistry, can solve problems such as being unfavorable to industrialized operation, complicated and difficult to operate, and difficult to treat three wastes, achieving production cost and environmental protection advantages, simplifying industrial operation, and reducing impurity content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Add 300ml of toluene and 15g of crude compound (I) to a 500ml reaction flask, add 2.3g of potassium hydroxide under stirring, heat to reflux at 110°C, react for 20 minutes, cool and filter the precipitated solid, then add the solid to 150ml of methanol and stir well , filtered to obtain a white solid, dried at 50°C to obtain 11.3g of a white solid, purity: 96.28%, yield: 75.3%.

Embodiment 2

[0031] Add 150ml of toluene and 15g of crude compound (I) to a 250ml reaction flask, add 2.3g of potassium hydroxide under stirring, heat at 60°C for 3 hours, cool and filter the precipitated solid, then add the solid to 150ml of methanol and stir evenly, and filter to obtain White solid was dried at 50°C to obtain 12.3g of white solid, purity: 97.13%, yield: 82%.

Embodiment 3

[0033] Add 200ml of toluene and 20g of crude compound (I) to a 250ml reaction flask, add 5.0g of potassium carbonate under stirring, heat to reflux at 110°C, react for 18 hours, cool and filter the precipitated solid, add the solid to 200ml of dichloromethane and stir for 5 Minutes, 100ml of water was added to separate layers, and the lower layer was concentrated to obtain a light yellow solid, then the solid was added to 50ml of methanol and stirred evenly, filtered to obtain a white solid, dried at 50°C to obtain 16.7g of a white solid, purity: 97.44%, yield: 83.5% .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com