Method for producing fermented feed using kitchen waste dry powder

A technology of food waste and fermented feed, which is applied in animal feed, animal feed, applications, etc., can solve the problems of inability to fully exert the beneficial effects of fermented feed, damage to live bacteria and active substances, and consume huge heat energy, so as to improve the quality of livestock and poultry. Product quality, enhanced immunity, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

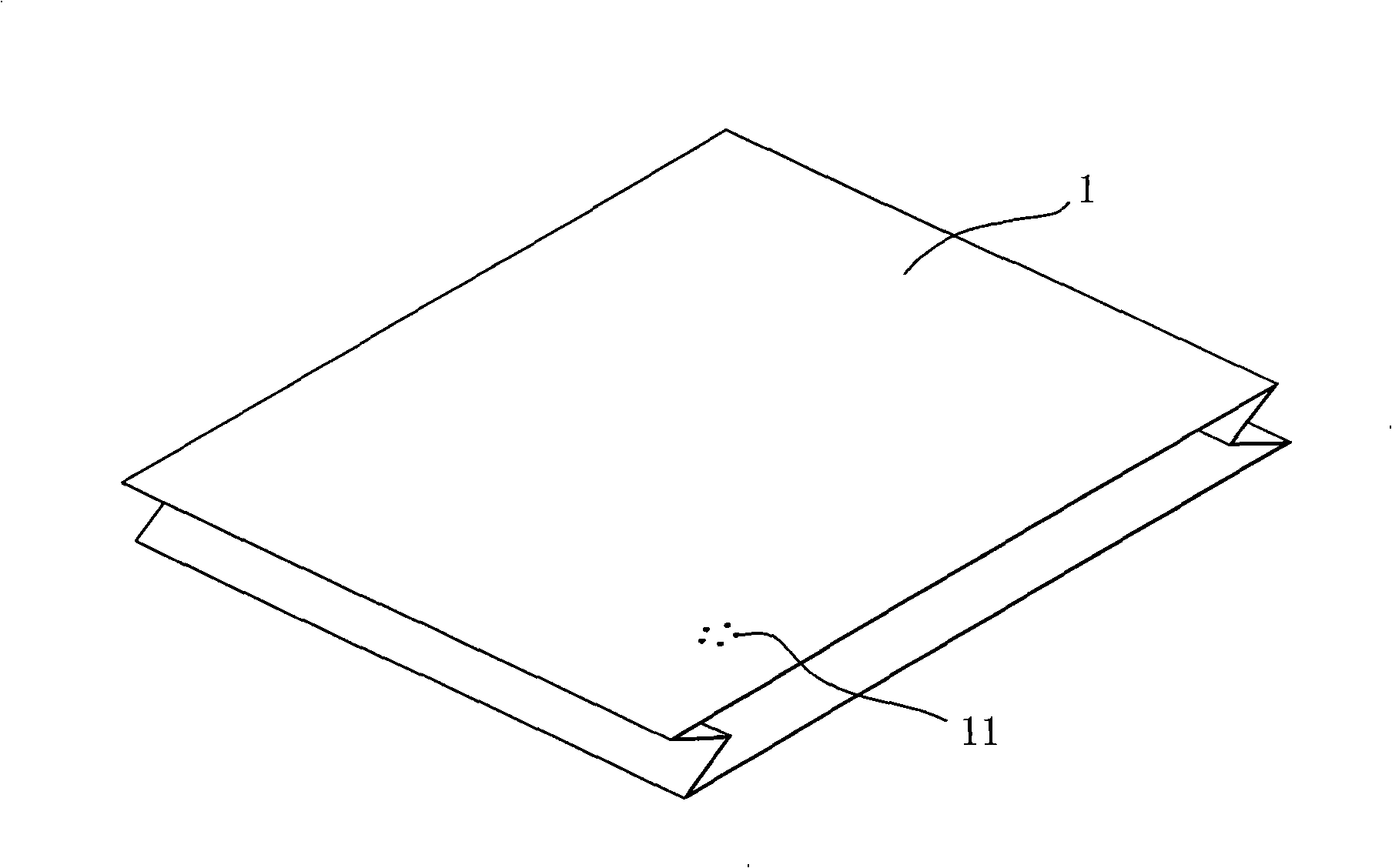

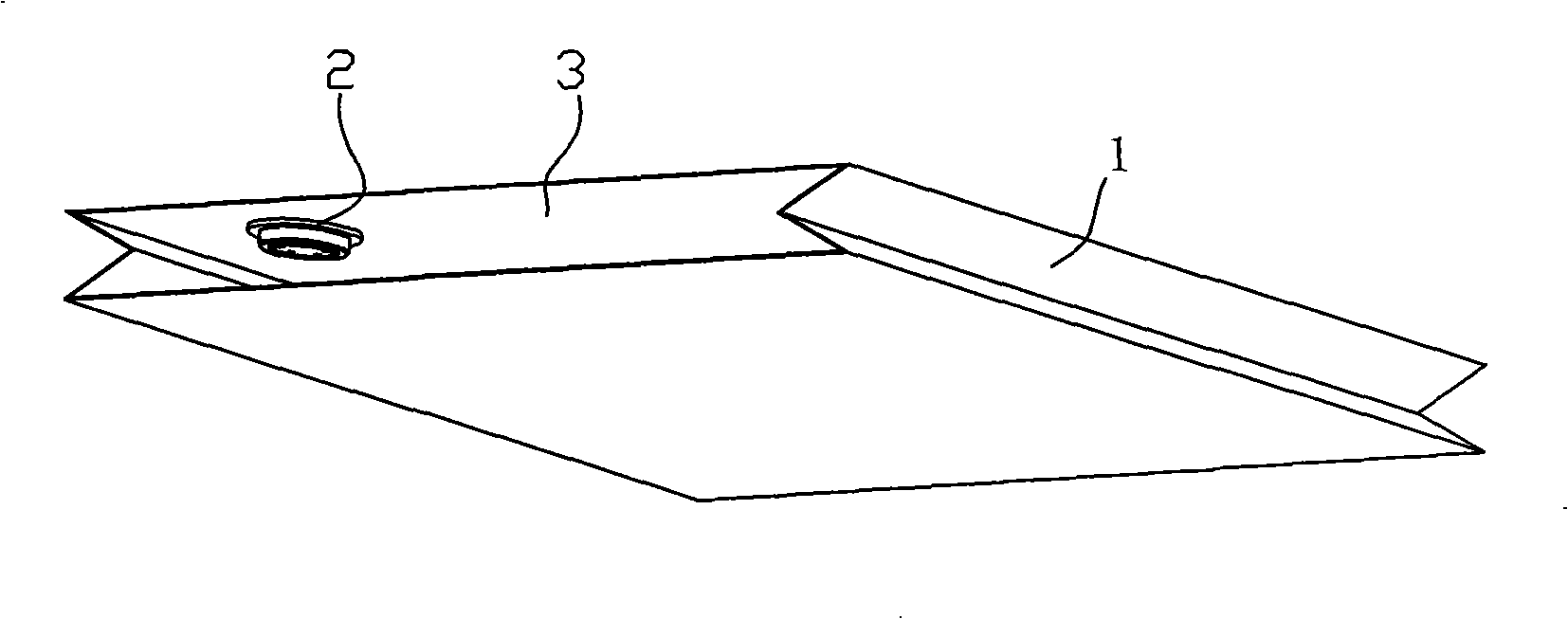

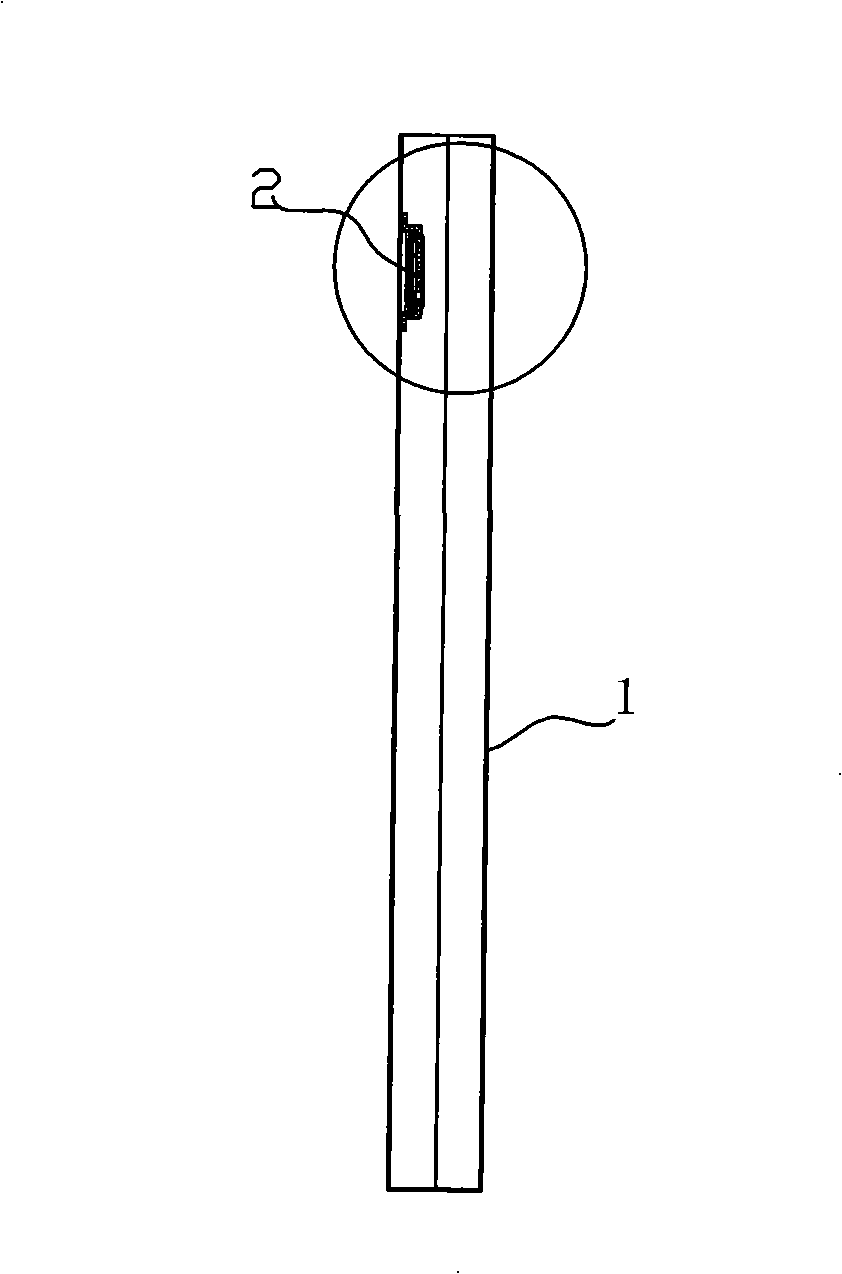

[0036] See Figure 1-3 , The one-way breathable valve 2 allows gas molecules to pass through in one direction, which can maintain the quality of the items in the bag for a long time. Through the technical improvement of the one-way breathable valve and packaging container materials, an anaerobic fermentation bag that can isolate oxygen and maintain anaerobic state is produced. Its structure includes a bag body 1 made of materials such as nylon, adhesive resin, enol copolymer, and a one-way ventilation valve 2 is installed on the surface of the bag body 1, and one end of the bag body 1 is temporarily open 3, when the inoculated After the food waste dry powder is loaded, it can be sealed and connected by thermal fusion technology. After the gas produced in the fermentation process reaches the set pressure, it is discharged through the one-way ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com