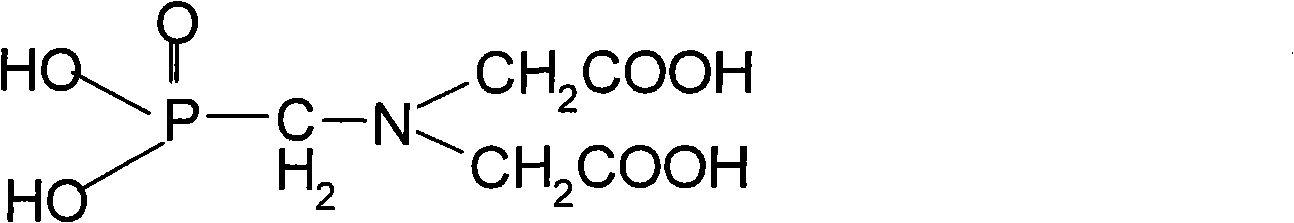

Comprehensive processing method of N-phosphonomethyliminodiacelic acid mother liquor

A comprehensive treatment, bis-glyphosate technology, applied in the field of comprehensive treatment of mother liquor containing sodium chloride, can solve the problems of environmental pollution, waste of resources, and insufficient comprehensiveness, and achieve the effect of low energy consumption and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1000 kg of mother liquor containing 1% diglyphosate and 16% sodium chloride produced in the production process of diglyphosate was pretreated with a precision filter device to remove impurities and colloids.

[0025] The pretreated mother liquor enters the nanofiltration system and is divided into two sections. The thick side is 96kg of concentrated liquid rich in diglyphosate, of which the concentration of diglyphosate reaches 9.5%, and sodium chloride is 17.3%. Phosphine 0.04%, sodium chloride 15.8%, operating pressure 3.0Mpa.

[0026] The dope with a diglyphosate concentration of 9.5% is fed into the diglyphosate synthesis system to recover the diglyphosate.

[0027] The effluent from the light side of the above-mentioned nanofiltration system enters the five-effect evaporator, the operating pressure of the series process is -0.05~0.15MPa, the steamed water directly enters the biochemical system, and the concentrated solution is centrifuged to obtain crude sodium chl...

Embodiment 2

[0032] Get the thick sodium chloride that obtains according to the embodiment 1 method, wherein contain sodium chloride 97.1%, total organic carbon 150ppm, total phosphorus 450ppm, total nitrogen 360ppm.

[0033] After the above crude sodium chloride was incubated at 1100° C. for 2 hours, the sodium chloride content was 98.1%, the total organic carbon was 6 ppm, the total phosphorus was 416 ppm, and the total nitrogen was 18 ppm.

[0034] Add water to dissolve the roasted sodium chloride and prepare salt water to make the sodium chloride content reach 20%, adjust pH=10.5 with 10% sodium hydroxide, add calcium chloride with 2.0% weight of salt water, and keep warm for 2.0hr at 20-30°C At the end of the heat preservation, add 0.5% PAM polymer flocculant by weight of brine, continue stirring for 0.5 hr, and filter and separate. The filtrate contains 0.8 ppm of total phosphorus, 0.6 ppm of organic carbon, and 1.6 ppm of total nitrogen.

[0035] After the above steps, the refined b...

Embodiment 3

[0037] Get the thick sodium chloride that obtains according to the embodiment 1 method, wherein contain sodium chloride 97.1%, total organic carbon 150ppm, total phosphorus 450ppm, total nitrogen 360ppm.

[0038] After the above crude sodium chloride was incubated at 1100° C. for 2 hours, the sodium chloride content was 98.1%, the total organic carbon was 6 ppm, the total phosphorus was 416 ppm, and the total nitrogen was 18 ppm.

[0039] Add water to dissolve the thick sodium chloride after the above-mentioned roasting and prepare salt water, so that the sodium chloride content reaches 20%, adjust the pH=10.5 with 10% sodium hydroxide, add magnesium chloride with 1.5% weight of salt water, and keep the temperature at 20-30°C for 4.0hr. At the end of the heat preservation, add 0.3% PAM polymer flocculant by weight of brine, continue stirring for 1 hr, filter and separate, and the filtrate contains 1.1 ppm of total phosphorus, 0.7 ppm of organic carbon, and 2.4 ppm of total nitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com